The YPWLC finalists normally gather in the city where the final is to be held ahead of time, to have the opportunity to get to know each other and exchange experiences. They also have a programme of technical, cultural and social visits based around the competition, so that they get to know something of the country they are visiting and experience its culture and industry.

The IOM3 Young Persons' World Lecture Competition has been held annually in different locations around the globe since 2005. Past events have taken place in the UK, Malaysia, Singapore, the US, Brazil, Hong Kong and Australia.

Winner - South Africa

Sebasa Theresa Ramahlare

2nd Place - FEMS

Oliver Marian Preuß

3rd Place - Malaysia

Jerome Liew

Hong Kong

Sihao Yu

Winner - South Africa

Sebasa Theresa Ramahlare

Sebasa is from Mohodi ga Manthata, a village in the Limpopo province, South Africa. She has a BSc in Chemical Engineering from the University of Witwatersrand and is currently working at the Council for Scientific and Industrial Research (CSIR) in the Pretoria Gauteng province. She is on a 3-year graduate-in-training programme in the Advanced Polymer and Composites (APC) group in the Chemicals cluster, currently working on a project titled 'Biodegradable films: Potential Environmentally Friendly Alternative for Agricultural Mulching'.

Sebasa hopes to pursue my postgraduate MSc in Chemical Engineering in 2025.

Biodegradable Mulch Biofilms Potential Environmentally Friendly Alternative for Agricultural Mulching

Plastic mulching materials are used in agriculture, providing advantages to crop production. Conventional plastic mulch presents challenges with disposal, increasing pollution, and breakdown into microplastics, leading to ecological problems. The current materials are synthetic and nondegradable, raising environmental concerns. This work was conducted to develop biobased plastic materials from biopolymers and biomass waste residues. Local biomass was used to modify biodegradable polymers to tailor biodegradability to suit the mulching of different lifecycles.

The physical and chemical properties of the materials were studied. The optimized mulch plastics were taken for laboratory and agricultural field trials to test the value proposition and practicality of use. The results revealed good properties comparable to conventional nonbiodegradable mulch plastics, with the added advantage of 100% biodegradability. These offer a sustainable alternative to traditional plastic mulch, which reduces plastic pollution.

2nd Place - FEMS

Oliver Marian Preuß

Oliver studied Materials Science at the Technical University of Darmstadt, Germany. After investigating the mechanical properties of diamond coatings during his Bachelor's thesis, he did his Master's thesis in the field of dislocations in ceramics in 2021, under the supervision of Dr Xufei Fang. Continuing this topic, he started a PhD on dislocation-based toughening in ceramics co-supervised by Prof Dr Jürgen Rödel and Dr Xufei Fang.

Oliver attended 3 international (incl. USA and Japan) and 5 national conferences and was the winner of the 2024 FEMS Master Thesis Award. His first paper achieved 'Editor’s Choice' by the American Ceramic Society and he also won three prizes in the ceramographic competition of the American Ceramic Society, including the Roland B Snow award for best-of-show. In his free-time, he practices luthiery and builds his own guitars.

Dislocation-Based Toughening and Damage-Tolerance in Oxide Ceramics

The growing research interest in dislocation tuned functionality in ceramics is evident, with the most recent proofs of concept for enhanced ferroelectric properties, electrical conductivity, and superconductivity via dislocations. In this study, we focus on dislocation-tuned mechanical properties and demonstrate that, by engineering high dislocation densities (up to 1014 per m2) into KNbO3 at room temperature, the fracture toughness can be increased by a factor of 2.8 compared to the reference.

A strong interaction between the dislocations and the ferroelectric domains was found, whose effect on the toughness is ruled out by a high-temperature indentation experiment. By an improved deformation technique, the dislocation density in MgO can reach over 1015 per m2, which leads to full crack suppression.

3rd Place - Malaysia

Jerome Liew

Jerome Liew is a PhD candidate at Universiti Malaya (UM) studying Doctor of Philosophy in Physical Science. He is zealous in his research in energy storage devices and has participated in numerous exhibitions, competitions, and conferences with awards. He won top 3 in Faculty of Science 3-Minute Thesis at UM twice consecutively, and actively took part in International Invention, Innovation & Technology Exhibition (ITEX’23 & ITEX’24).

He and his group won a Gold Award and a special award in ;Technology Reversing Climate Change' in ITEX’23. Recently, he received a scholarship to attend Green Chemistry Summer School in Venice, Italy. He aspires to make technological advancements in the field of energy storage devices and desires to bring breakthroughs in electrified vehicles in the advent of Electric Vehicles.

MXene: Pursuing Fast-Charging Battery

The presentation exploits the properties of MXene in its incorporation with silicon-based anodes. Various MXene synthesis methods were examined for the best MXene without the direct usage of hydrofluoric acid. Silicon anode faces the issue of massive volumetric changes during charging and discharging that cause its pulverisation, limiting its practical applications.

By electrostatic assembly of MXene and silicon and the coating of the composite thereof, the exorbitant aspect ratio of MXene provides extra active sites for redox reaction, and the 3D matrix formed by MXene establishes electronic transport pathways and promotes carrier transfer, increasing rate performance. The matrix also provides mechanical integrity to the composite, confining silicon nanoparticles from pulverising, and improving the longevity of silicon anodes. This concurrently addresses the restacking phenomenon of MXene due to the intercalation of silicon nanoparticles, demonstrating the synergistic effects of the composite.

UK

Emilia Russell

Emilia Russell is a 2nd year PhD student in the Department of Engineering at Durham University, currently investigating the impacts of mechanical strain on the electrical properties of 2-dimensional semiconductors. In her free time, she enjoys sailing and organising seminars from industry speakers with the Women’s Engineering Society at Durham.

Why strained semiconductors are like crinkle-cut crisps

When applying strain to 2-dimensional transition metal dichalcogenides, it has been observed that the bandgap changes. The bandgap is the potential difference between the highest energy bounded (immobile) electrons and the delocalised (mobile) electrons.

Crinkle cut crisps taste better because they hold more salt, crinkle cut semiconductors insulate better because they hold more electrons.

This effect could be exploited in the next generation of synthetic skin. It could also be used to design flexible acetylene detectors to monitor food expiration, reducing food waste. To date, the relationship between mechanical strain and electronic properties has predominantly been shown through computational modelling. This research focuses on overcoming the issues that have hindered the realisation of these devices, such that the effects of strain on other semiconductor properties can be investigated. In turn, this will lead to a better understanding of the electrostatics and charge transport of these novel 2-D materials.

Hong Kong

Sihao Yu

Sihao is a 2nd year PhD student in the Department of Earth Sciences at the University of Hong Kong, under the supervision of Prof Louis Wong. He earned his BEng (2020) in Civil Engineering from Southeast University, China, followed by an MPhil (2023) in Geotechnical Engineering from Tongji University, China. His current research focuses on the application of artificial intelligence in geotechnical engineering practice, particularly advanced computer vision techniques.

In his spare time, Sihao enjoys outdoor activities like hiking and ball games

A deep learning-based framework for automatic rock core logging

Rock core logging plays a crucial role in obtaining geological and geotechnical information such as lithology and Rock Quality Designation (RQD). However, traditional rock core logging procedures are often tedious and time-consuming, especially for highly fractured rock cores. Have you ever imagined that such domain-professional work could be aided by artificial intelligence? Prof Louis Wong and his research team at HKU have developed an autonomous framework for performing core logging that mimics human processes.

This presentation will showcase ongoing research to further improve automatic lithology classification and RQD estimation. A deep learning-based framework has been trained to classify rock cores into different categories. Moreover, this framework can also segment cores at a high accuracy, allowing the subsequent automatic RQD calculation. Upon further verification, the plan is to update the framework and integrate it into a publicly accessible website for widespread use.

2024 - online

2024 - online

Winner - South Africa

Sebasa Theresa Ramahlare

2nd Place - FEMS

Oliver Marian Preuß

3rd Place - Malaysia

Jerome Liew

Hong Kong

Sihao Yu

Winner - South Africa

Sebasa Theresa Ramahlare

Sebasa is from Mohodi ga Manthata, a village in the Limpopo province, South Africa. She has a BSc in Chemical Engineering from the University of Witwatersrand and is currently working at the Council for Scientific and Industrial Research (CSIR) in the Pretoria Gauteng province. She is on a 3-year graduate-in-training programme in the Advanced Polymer and Composites (APC) group in the Chemicals cluster, currently working on a project titled 'Biodegradable films: Potential Environmentally Friendly Alternative for Agricultural Mulching'.

Sebasa hopes to pursue my postgraduate MSc in Chemical Engineering in 2025.

Biodegradable Mulch Biofilms Potential Environmentally Friendly Alternative for Agricultural Mulching

Plastic mulching materials are used in agriculture, providing advantages to crop production. Conventional plastic mulch presents challenges with disposal, increasing pollution, and breakdown into microplastics, leading to ecological problems. The current materials are synthetic and nondegradable, raising environmental concerns. This work was conducted to develop biobased plastic materials from biopolymers and biomass waste residues. Local biomass was used to modify biodegradable polymers to tailor biodegradability to suit the mulching of different lifecycles.

The physical and chemical properties of the materials were studied. The optimized mulch plastics were taken for laboratory and agricultural field trials to test the value proposition and practicality of use. The results revealed good properties comparable to conventional nonbiodegradable mulch plastics, with the added advantage of 100% biodegradability. These offer a sustainable alternative to traditional plastic mulch, which reduces plastic pollution.

2nd Place - FEMS

Oliver Marian Preuß

Oliver studied Materials Science at the Technical University of Darmstadt, Germany. After investigating the mechanical properties of diamond coatings during his Bachelor's thesis, he did his Master's thesis in the field of dislocations in ceramics in 2021, under the supervision of Dr Xufei Fang. Continuing this topic, he started a PhD on dislocation-based toughening in ceramics co-supervised by Prof Dr Jürgen Rödel and Dr Xufei Fang.

Oliver attended 3 international (incl. USA and Japan) and 5 national conferences and was the winner of the 2024 FEMS Master Thesis Award. His first paper achieved 'Editor’s Choice' by the American Ceramic Society and he also won three prizes in the ceramographic competition of the American Ceramic Society, including the Roland B Snow award for best-of-show. In his free-time, he practices luthiery and builds his own guitars.

Dislocation-Based Toughening and Damage-Tolerance in Oxide Ceramics

The growing research interest in dislocation tuned functionality in ceramics is evident, with the most recent proofs of concept for enhanced ferroelectric properties, electrical conductivity, and superconductivity via dislocations. In this study, we focus on dislocation-tuned mechanical properties and demonstrate that, by engineering high dislocation densities (up to 1014 per m2) into KNbO3 at room temperature, the fracture toughness can be increased by a factor of 2.8 compared to the reference.

A strong interaction between the dislocations and the ferroelectric domains was found, whose effect on the toughness is ruled out by a high-temperature indentation experiment. By an improved deformation technique, the dislocation density in MgO can reach over 1015 per m2, which leads to full crack suppression.

3rd Place - Malaysia

Jerome Liew

Jerome Liew is a PhD candidate at Universiti Malaya (UM) studying Doctor of Philosophy in Physical Science. He is zealous in his research in energy storage devices and has participated in numerous exhibitions, competitions, and conferences with awards. He won top 3 in Faculty of Science 3-Minute Thesis at UM twice consecutively, and actively took part in International Invention, Innovation & Technology Exhibition (ITEX’23 & ITEX’24).

He and his group won a Gold Award and a special award in ;Technology Reversing Climate Change' in ITEX’23. Recently, he received a scholarship to attend Green Chemistry Summer School in Venice, Italy. He aspires to make technological advancements in the field of energy storage devices and desires to bring breakthroughs in electrified vehicles in the advent of Electric Vehicles.

MXene: Pursuing Fast-Charging Battery

The presentation exploits the properties of MXene in its incorporation with silicon-based anodes. Various MXene synthesis methods were examined for the best MXene without the direct usage of hydrofluoric acid. Silicon anode faces the issue of massive volumetric changes during charging and discharging that cause its pulverisation, limiting its practical applications.

By electrostatic assembly of MXene and silicon and the coating of the composite thereof, the exorbitant aspect ratio of MXene provides extra active sites for redox reaction, and the 3D matrix formed by MXene establishes electronic transport pathways and promotes carrier transfer, increasing rate performance. The matrix also provides mechanical integrity to the composite, confining silicon nanoparticles from pulverising, and improving the longevity of silicon anodes. This concurrently addresses the restacking phenomenon of MXene due to the intercalation of silicon nanoparticles, demonstrating the synergistic effects of the composite.

UK

Emilia Russell

Emilia Russell is a 2nd year PhD student in the Department of Engineering at Durham University, currently investigating the impacts of mechanical strain on the electrical properties of 2-dimensional semiconductors. In her free time, she enjoys sailing and organising seminars from industry speakers with the Women’s Engineering Society at Durham.

Why strained semiconductors are like crinkle-cut crisps

When applying strain to 2-dimensional transition metal dichalcogenides, it has been observed that the bandgap changes. The bandgap is the potential difference between the highest energy bounded (immobile) electrons and the delocalised (mobile) electrons.

Crinkle cut crisps taste better because they hold more salt, crinkle cut semiconductors insulate better because they hold more electrons.

This effect could be exploited in the next generation of synthetic skin. It could also be used to design flexible acetylene detectors to monitor food expiration, reducing food waste. To date, the relationship between mechanical strain and electronic properties has predominantly been shown through computational modelling. This research focuses on overcoming the issues that have hindered the realisation of these devices, such that the effects of strain on other semiconductor properties can be investigated. In turn, this will lead to a better understanding of the electrostatics and charge transport of these novel 2-D materials.

Hong Kong

Sihao Yu

Sihao is a 2nd year PhD student in the Department of Earth Sciences at the University of Hong Kong, under the supervision of Prof Louis Wong. He earned his BEng (2020) in Civil Engineering from Southeast University, China, followed by an MPhil (2023) in Geotechnical Engineering from Tongji University, China. His current research focuses on the application of artificial intelligence in geotechnical engineering practice, particularly advanced computer vision techniques.

In his spare time, Sihao enjoys outdoor activities like hiking and ball games

A deep learning-based framework for automatic rock core logging

Rock core logging plays a crucial role in obtaining geological and geotechnical information such as lithology and Rock Quality Designation (RQD). However, traditional rock core logging procedures are often tedious and time-consuming, especially for highly fractured rock cores. Have you ever imagined that such domain-professional work could be aided by artificial intelligence? Prof Louis Wong and his research team at HKU have developed an autonomous framework for performing core logging that mimics human processes.

This presentation will showcase ongoing research to further improve automatic lithology classification and RQD estimation. A deep learning-based framework has been trained to classify rock cores into different categories. Moreover, this framework can also segment cores at a high accuracy, allowing the subsequent automatic RQD calculation. Upon further verification, the plan is to update the framework and integrate it into a publicly accessible website for widespread use.

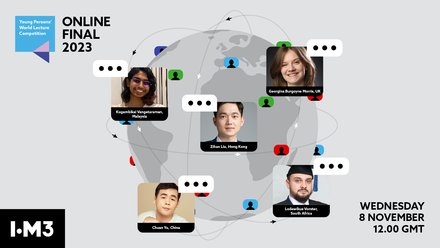

2023 - online

2023 - online

Winner - South Africa

Lodewikus Vorster

2nd place - Malaysia

Kugambikai Vangetaraman

3rd place - UK

Georgina Burgoyne Morris

Hong Kong

Zihan Liu

China

Chuan Yu

Winner - South Africa

Lodewikus Vorster

Lodewikus is a first-year master's student in the field of physical chemistry and electrochemical analysis. In 2022, He achieved his honours degree, leaving an indelible mark with a project that sought to revitalize the green hydrogen production initiative in South Africa. This endeavour was about making clean energy solutions accessible to all by enhancing efficiency and reducing costs. In 2023, Lodewikus embarked on an exciting journey as a research student at eNtsa. This experience has been nothing short of transformative, igniting a fervent passion for the world of engineering and materials research.

Beyond the laboratory, Lodewikus is an enthusiast of renewable energy and its possibility to improve the lives of everyone. His spare time is often spent expanding his skill set to enter industry where he can start making his mark.

Cyclic potentiodynamic polarization testing of TIG welded 316L stainless steel for characterization of pitting corrosion

This presentation focuses on the characterization of pitting corrosion in 316L stainless steel in response to Tungsten Inert Gas (TIG) welding parameters. The presentation will begin by providing a concise overview of pitting corrosion theory before introducing the results of the investigation. Cyclic potentiodynamic polarization testing was conducted to measure the susceptibility of the three different weld zones (base metal, heat affected zone, weld root) present in welded 316L stainless steel to pitting corrosion under different welding conditions.

The presentation will also discuss microstructure analyses of both heat-treated and untreated samples through Scanning Electron Microscopy / Energy Dispersive Spectroscopy (SEM-EDS), offering insights into the material's structural responses. The presentation will conclude with the introduction of a full factorial experimental setup designed to evaluate pitting corrosion in relation to TIG welding variables.

2nd place - Malaysia

Kugambikai Vangetaraman

Kugam is currently pursuing her fast-track doctorate programme in Biomedical Engineering upon completion of her degree programme with first class honours in the year 2022. Kugam’s passion in research works instigated her to further improve on her degree project in developing vascular patch. Her research interest covers biomaterials and mainly focuses on electrospinning of polymers. Kugam had shared her research innovation during the IJN-UTM Research Convention 2023 and secured third place in the Innopitch Competition held during the 5th International Innovation Day 2023 in UTM. She sincerely envisions making healthcare accessible to all and believes research and innovation is one of the medium to achieve so. Besides research, her side interests would be weightlifting, yoga and she enjoys witticism.

Band aids for blood vessels: Co-electrospinning of polyurethane/chitosan & polyvinyl alcohol/elastin for vascular patch development

Coronary heart diseases build up fatty deposits occluding blood vessels and restricting blood flow. Surgical treatment is required to substitute the defective tissues with vascular patches. However, current commercialized synthetic vascular patches are non-biodegradable and lead to thrombosis. Therefore, there is a need for biodegradable synthetic polymers such as polyurethane (PU) and polyvinyl alcohol (PVA) for the development of vascular patches. The blending of natural polymers such as chitosan (CS) and elastin (EL) in the matrix of biodegradable polymers strongly enhances the mechanical and biological properties. Electrospinning is a prominent technique for the fabrication of fibrous vascular patches, as it enables polymer to be blended in achieving the desired properties mimicking native vessels.

Thus, this lecture emphasizes the introduction of PU/CS and PVA/EL co-electrospun vascular patch, which exhibits biodegradability, elasticity and anti-thrombogenicity, besides being biocompatible and biofunctional to support its implementation as a vascular patch.

3rd place - UK

Georgina Burgoyne Morris

Georgie is a first year PhD student at the Department of Materials Science & Metallurgy at the University of Cambridge, where she stayed having completed her undergraduate degree in Natural Sciences, specialising in Materials Science. Her research, within the Photoactive Materials group, surrounds the development of self-healing polymeric hosts for triplet-triplet annihilation upconversion – a process by which the efficiency of solar cells could be boosted through the ability to usefully harvest sub-bandgap photons.

When she’s not in the lab, Georgie enjoys cooking, playing music, and going to pub quizzes.

Stimuli-responsive polymers as self-healing materials

The ability to autonomously repair damage can lead to significant improvements in lifetime and recyclability of polymeric materials, reducing both waste and production costs. This may be achieved either extrinsically, through the release of healing agents encapsulated in the polymer matrix, or intrinsically, as a result of dynamic interactions between the polymer chains themselves. The latter systems have the advantage that their healing ability is not reliant upon the presence of a secondary reactive species, giving potential to repair more extensive or repeated damage.

This talk will discuss how, through tuning their chemistry, polymers can be made to intrinsically self-heal under ambient conditions, or in response to external stimuli such as heat or light. It will also explore the variety of applications for these materials, from healable protective coatings to recyclable thermoset resins.

Hong Kong

Zihan Liu

Zihan is a 2nd year PhD student in the Department of Earth Sciences at the University of Hong Kong, under the supervision of Dr Louis N Y Wong. He completed a BEng (2019) and MPhil (2022) in Civil Engineering at China University of Geosciences and Shanghai Jiao Tong University, respectively. His research mainly focuses on rock mechanics. His works have been published in journals like Rock Mechanics and Rock Engineering. Zihan tries to understand the complex thermal response of rock materials through experimental and numerical methods. He believes this fundamental research can further expand the knowledge of geotechnical engineering disciplines and promote the development of deep underground space and energy.

In his spare time, Zihan likes playing basketball, running, and swimming. He also enjoys travelling, where he can learn and experience different cultures and lives.

How does thermal shock affect rocks?

Have you ever wondered how ancient civilizations break giant rocks without drilling tools or explosives? They harnessed the power of thermal shock by heating rocks first and then cooling them rapidly. Rocks are composed of various minerals with different thermal expansion coefficients and thermal conductivity. When rocks experience rapid heating or cooling, temperature change-induced thermal deformation differs among adjacent mineral grains and thus creates intragranular and intergranular microcracks. Thermal shock sometimes changes the microstructure of rocks and thus permanently alters the physico-mechanical properties of rocks.

Through theoretical and experimental investigation, the mechanical response of rocks under thermal shock loading and influencing factors of thermal shock can be comprehended. Thermal shock has been applied in thermal spallation drilling for excavation and thermal stimulation for reservoir penetration enhancement.

This presentation will provide an overview of the mechanism, influencing factors, and applications of thermal shock in civil engineering.

China

Chuan Yu

Chuan is a graduate of Queen Mary Engineering School where he obtained his bachelor’s degree in Polymer Materials and Engineering. Under the supervision of Dr. Han Zhang and Prof. Guangcheng Zhang, his final year project focused on the 3D Printing of polymer composite and its application in energy absorption structure design. After completing his undergraduate program, Chuan is now pursuing a Master’s degree in the School of Biomedical Engineering at McMaster University where he studies the application of polymer material in health-related fields.

In his personal life, Chuan enjoys reading, baking and doing outdoor sports. He also likes music and is often found relaxing himself with Blues or light music.

Novel Energy Absorption Structure based on 3D Printed Polymer Blend System

Energy absorption structure (EAS) is a type of material system designed to absorb high kinetic mechanical energy through irreversible deformation, which is widely used in many applications. This research project selected Fused Deposition Modelling (FDM) method to build up different EAS with a TPU-PVDF polymer blend system. Totally, there are two design strategies used in this project: the gradient configuration design where the EAS is given a gradient structure and the hierarchical design where multi-scale pores are introduced into the EAS.

The success of the two designs in this project strongly depends on the application of FDM 3D printing method whose specific processing procedure will be given in this presentation, together with the performance of the EAS created to evaluate the design strategies used.

2022 - online

2022 - online

Winner - Malaysia

Rathosivan Gopal

2nd place - UK

Lauren Eggleton

3rd place - Canada

Kate Fraser

South Africa

Shane de Beer

China

Tianyi Li

Hong Kong

Danning Li

Winner - Malaysia

Rathosivan Gopal

Rathosivan graduated in Bachelor of Engineering (Bio-Medical) from Universiti Teknologi Malaysia (UTM) with first class distinction in the year 2019. He was then offered to pursue fast-track doctorate programme in School of Biomedical Engineering and Health Sciences and managed to secure financial aid from student excellence program by Malaysia public service department (PPC-JPA) to further his studies. His research focuses on utilisation of biomaterials especially polymers and hydrogels as an implant material and has skilled in operating several high-end analysis instruments as well as performing in-vitro analyses. He is currently completing his six months training attachment at Laval University, Canada funded by the Canadian government. Ratho has presented his preliminary research work in Quebec, Canada at the QCAM student symposium 2022 and virtually at Japan in the 8th ICCME 2021 conference in the field of biomaterials, polymer and mechanics. Recently, he won the 3 Minute Thesis competition in UTM and represented the university to the national level. He also has been the organising committee for 8th and 9th IGCESH (2020, 2022) conference and gained valuable experiences in managing hybrid big-scaled events.

Apart from academic relations, Ratho has led several student associations during his doctorate study such as postgraduate student society (PGSS 2019/2020) and residential college student committee (JKM 2020/2021). Together with his team members, Ratho has organised variety of programs to engage students actively participate in activities outside their academic field and cope with the pandemic while excelling in their studies and research. As a graduate engineer and a researcher, he is keen in giving back to the community to raise awareness and help young students and kids to engage in STEM programs. He enjoys participating in charity programs and always willing to lend a helping hand to develop the community.

Immobilisation of factor VII through polydopamine grafting of polycaprolactone membrane for cardiac bleeding

The repair of cardiac bleeding is one of the processes in the treatment of cardiovascular diseases. Nevertheless, postoperative bleeding is still an issue following the implementation which derange the resources and cost. Oral administration of blood coagulation protein called Factor VII (FVII) has been effective to stop the bleeding. However, the short half-life may loss its effectiveness and frequent intake may distress the patient. Alternatively, synthetic polymers such as polycaprolactone (PCL) is used in drug delivery and wound dressing applications due to its favorable properties. Therefore, this study immobilises FVII on PCL membrane through polydopamine grafting using dropcasting technique to seal the bleeding at its maximum region and accelerate blood coagulation. The PCL membrane was used to graft a thin polydopamine film as the intermediate layer to enhance the surface compatibility and provide a platform for immobilisation of Factor VII afterwards.

The physio-chemical properties of the thin PCL membranes were characterized using several analyses. While the cytocompatibility of the membranes was evaluated with fibroblast and blood cells. Initial characterisation studies showed the success of FVII immobilisation through polydopamine grafting and the presence of FVIImolecules on the PCL membrane with enhanced surface roughness and hydrophilicity. While the biocompatibility tests showed increased cell viability and coagulation and the lowest haemolysis ratio on FVII immobilised PCL membrane. This validates the biocompatibility of the membrane and its ability to accelerate blood coagulation and potential application as cardiac bleeding sealant. Future works will focus on the mechanical strength and incorporation of adhesive component to the membrane.

2nd place - UK

Lauren Eggleton

Lauren is a second year PhD student in the Materials Science and Engineering Department at The University of Sheffield. She developed a passion for research during her Masters in Materials Science and Engineering, which specialised in biomaterials. During this time, she undertook a year in industry at Philips Research UK, working in oral healthcare on whitening and hypersensitivity. Upon returning, she channelled her love for research and nature into her master’s project on snail and slug locomotion in the Natural Materials Group, and has never looked back. Her EPSRC funded PhD focuses on understanding and bridging the gap between structure and function in snail and slug mucus.

Within the department and faculty, she is an active member of the postgraduate research community: supporting fellow students as part of the postgraduate research committee, helping teach undergraduates, and sharing research stories over arts and crafts lunches. Outside of the lab, she is a keen communicator and advocate for inclusion and diversity in STEM subjects, volunteering for outreach programmes and school events at both the local and national level. Through her work with the Bioladies Network and Natural Materials Association, she hopes to inspire people across all ages and backgrounds to discover the scientific wonders found in nature.

In her free time, Lauren enjoys exploring the Peak District, medieval re-enactment and has recently taken up ice skating. Though she can often be found at home curled up with a good book and her two cats.

A sticky situation: The contradictory material properties of snail mucus

Nature has evolved a vast range of 'smart' materials and is currently an untapped resource for novel biomedical and engineering applications. A surprising example is snail mucus. Embodying two contradictory properties, adhesion and lubrication, this material can switch seamlessly between them whenever the functional need arises. But how does it do this and can we replicate it?

In the search to understand these unusual flow properties, our creation of a snail locomotion translation device demonstrates how a more holistic approach to analysing natural materials can reveal more about their true nature. Discovering that like many industrial materials, snail mucus crystallises, but controlling this is via an elegant means of changing its salt concentration. Showing that we can find inspiration for tomorrow's advanced materials everywhere, even at the bottom of our garden.

3rd place - Canada

Kate Fraser

Kate is a PhD candidate in the Department of Chemistry at Simon Fraser University, supervised by Dr Steven Holdcroft. After completing her Bachelor’s and Master’s in Chemistry at Lancaster University in the UK, she moved to Vancouver, Canada to pursue her PhD. Her research field works to develop and improve devices to make hydrogen a viable replacement for fossil fuels. Kate’s research interests within this field lies in the design, synthesis, and characterisation of novel polymer electrolytes and binders for integration into alkaline electrolyzers and fuel cells. The main focus of Kate’s PhD is to develop a highly conductive polymer that can withstand the highly caustic, high temperature environments of the alkaline devices.

Within the Department Kate is an active member of the Chemistry Graduate Student Caucus and works to support and connect the students through weekly social events. Outside of the department Kate is part of the Electrochemical Society Student Chapter and has organised virtual and in-person symposiums which included speakers and attendees from various places in North America.

In her personal life, Kate is often found road biking around the Vancouver Lower Mainland and the various islands. And when the winter comes, Kate likes to ski at the nearby mountains.

Plastics for renewable energy devices

Plastics, also known as polymers, are long molecular chains that interweave with themselves to form complex structures like that of felted wool. These materials have proved to be essential in achieving a net-zero carbon economy through their usage in energy storage and conversion devices.

Hydrogen has the ability to store a large amount of energy, much like gasoline. However, unlike fossil fuels which release greenhouse gases, hydrogen only produces water when combusted. An Electrolyser uses excess renewable energy to create hydrogen fuel which stores energy. Fuel Cells then use hydrogen to generate energy and power transportation devices. Specific polymers have been developed to replace caustic liquids within the devices, creating systems that are safer, more compact, and more efficient. However, strongly basic solutions destroy the polymer structure resulting in material degradation and device failure. Here, polymers have been developed to withstand such conditions whilst maintaining high device efficiencies.

South Africa

Shane de Beer

Shane is an aspiring academic in the field of theoretical and computational chemistry. He is currently in his second year of PhD at Stellenbosch University after completing his BSc and MSc studies at the University of Pretoria. His research interests include investigating the quantum mechanical nature of materials and using this insight as a basis for developing novel materials, especially catalysts. During his previous studies, he explored chemical bonding in molecules using atomistic theoretical techniques and is now seeking to understand bonding in solid-state materials on a similar basis, as well as supplementing theoretical insights with experimental results from spectroscopy and x-ray diffraction. During his PhD, he is developing theoretical models on adsorption and photocatalysis in the solid-state to capture and convert unwanted products into more useful reagents. Shane has presented his work at ISXB4, ePCCr, AfPS-2021 and the 15th CHPC National Conference. He also published the first step in his journey in the Journal of Computational Chemistry. In future, he aspires to develop theories and techniques to further investigate the quantum behaviours of materials.

When Shane is not working, he can be found in the world of a thriller novel or enjoying the company of his two dachshunds. Otherwise, he is trying his hand at a new recipe or a new language.

Overcoming limitations on computational adsorption modelling for flexible materials

Experiments to determine sorption isotherms can take up to weeks to complete whereas computational modelling of sorption isotherms only takes a few hours. The software available limits the adsorbing materials to rigid structures, whereas modern research has shown that many materials of interest undergo structural changes upon guest adsorption.

There are many applications in gas separation, gas storage and catalysis that can utilize this flexibility. However, modelling the isotherm of a flexible material as a rigid structure can lead to inaccurate isotherm models. Here a stepped method is developed to model the isotherms of flexible materials accurately, utilizing the Materials Studio sorption module as well as the CASTEP software. The predicted isotherm for CO2 adsorption onto the MOF-508 material is then tested against the experimental isotherm to validate the proposed method. This, furthermore, gave fundamental insights into the mechanism for the adsorption of CO2 onto MOF-508.

China

Tianyi Li

Tianyi is now a Master's student in the state key laboratory of polymer material engineering in Sichuan University, supervised by Prof Zhongming Li. His research is focused on the advanced polymer processing technology by machine learning. Prior to this, he obtained his Bachelor's degree in Engineering in polymer material science and engineering with first class from Queen Mary University of London and Northwestern Polytechnical University under the supervision of Dr Han Zhang and Prof Yanhui Chen. His dissertation investigated the aerogel which can be used as EMI shielding material.

Tianyi is also an active member in the field of swimming.He has been taking professional training from 10 years old and became champion in the provincial college students' competition in 2019. He now works as the referee in swimming competitions.

MXene/rGO@PI aerogel with excellent EMI shielding performance

With the requirement to fabricate polymer aerogel that can be able to use in high EMI shielding, lightweight and heat resistance application, MXene/rGO@PI aerogel composite have been fabricated in a facile method combined dip-coating and direct foaming process to ensure the structural integrity and MXene adsorption, with an average shielding effectiveness of 25.37 dB and absorption coefficient (A) of 75% successfully achieved by 6.14 wt% rGO filling and 12.33 wt% MXene filling. The structure was strengthened by chemical and physical interaction between filler and matrix, and inner conductive network improved the thermal conductivity to enable better heat resistance. The fabricated aerogel offers potential uses in next-generation communication technology, miniaturised portable electronic devices and aeronautics and astronautics.

Hong Kong

Danning Li

Danning is a PhD candidate in the Department of Civil and Environmental Engineering at the Hong Kong Polytechnic University, supervised by Dr Leng Zhen. His research interests focus on sustainable pavement materials and technologies, especially the rubberized asphalt material. His PhD dissertation topic is “Multiscale Investigation on the Aging and Recycling Mechanisms of Asphalt Rubber Pavement”. With a good command of rheological, mechanical, and chemical analysis methods, he aims to interpret the intricate aging mechanism of asphalt rubber binder and develop customized rejuvenation methods for reclaimed asphalt rubber pavement to further promote the application of asphalt rubber pavement and disposal of waste tire rubber. Danning has presented his work at Transportation Research Board Annual Meeting, International Association of Chinese Infrastructure Professionals Conference, and International Transportation PhD Student Symposium. His works have been published in journals including the Journal of Cleaner Production, Materials & Design, and Resources, Conservation & Recycling.

In daily life, Danning has always been praised as versatile thanks to his proficient skills at playing the piano and basketball. His passion for these two hobbies is the power source of his life and always fuels his pursuit of research.

Investigation on the aging mechanism of asphalt rubber binder prepared with waste tire rubber

Asphalt Rubber (AR) is a sustainable paving material composed of bitumen and crumb waste tire rubber. AR presents enhanced pavement rutting and cracking resistance, and considerable environmental benefits including reduced tire-road noise and waste tire disposal. However, the aging mechanism of AR binder remains unclear due to the intricate rubber-bitumen interaction, which complicates the recyclability of reclaimed AR pavement (RARP).

Aiming at a deeper understanding on the aging mechanism, this presentation investigates the compositional and mechanical evolution of AR binder through experimental methods and micromechanical modelling. As a multiphase material, AR binders at different aging conditions were phase-separated to reveal the structural change during aging. Chemical tests were conducted to observe the rubber absorption behaviours during aging. Rheological tests and micromechanical evolution of AR binder and its components. The findings can provide theoretical support for the recycling and rejuvenation design of RARP.

2021 - Online

2021 - Online

The World Final took place virtually on 12 November.

Winner - Canada

Hannah Ramsay

2nd place - Malaysia

Farah Hannan Abd Nasir

3rd place - China

Juncheng Fan

UK

Mia Maric

Hong Kong

Dio Brian Billi

Russia

Ivan Perepletkin

South Africa

Shane de Beer

Winner - Canada

Hannah Ramsay

Hannah is currently an MD/PhD Candidate at Queen’s University, studying Chemistry. Previously, she obtained her BSc in Life Sciences and BEd in Secondary Education, also at Queen’s as part of the Concurrent Education program. Her research focuses on the applications of silver clusters, which are nanosized particles of silver that can be used for the combined diagnosis and treatment of disease. She is excited about helping realize the clinical applications of this material, and moving forward with this research in her role as a future clinician-scientist. Hannah’s research is supported by the Alexander Graham Bell CGS Doctoral Award, and has been published in several scientific journals, including Nanoscale.

Hannah is passionate about science and teaching, and helping others use science to understand the world around them. This has been recognized by several teaching awards, and Hannah was recently named a Top 50 graduate in 50 years at the Queen’s Faculty of Education. In her spare time, you can find Hannah performing in Chemistry magic shows, on the soccer field or hitting the ski slopes!

Silver Clusters: Small Material, Big Potential

Silver has been used since prehistoric times- in fact, it is one of the first five metals discovered by humans! What we commonly recognize as silver, for instance the silver in our jewelry, has all the properties of a bulk metal; it is conductive, shiny and malleable. As we look at silver on a smaller and smaller scale, its properties actually change. At nanoscale sizes, silver starts to look red or even yellow in colour. We can use these tiny molecules of silver to do a ton of interesting things, from looking at new drug therapies, to biological imaging to producing solar energy. By controlling the exact size and composition of these molecules, you can target specific cells and binding sites in the body. The goal of my research is to deeply understand this material and investigate how these really small particles can lead to big opportunities.

2nd place - Malaysia

Farah Hannan Abd Nasir

Farah Hannan Abd Nasir graduated with a Bachelor of Science (Hons) Applied Chemistry from International Islamic University Malaysia (IIUM) in 2017. She is currently a Graduate Research Assistant pursuing her doctoral studies at the Low Dimensional Materials Research Centre (LDMRC) at the Faculty of Science, Universiti Malaya. Her research interests include organic electronics particularly organic light-emitting diodes (OLEDs), computational and theoretical chemistry and doping mechanisms in organic semiconductors. She is also interested to incorporate machine learning and artificial intelligence as an application to design more efficient organic light-emitting diodes. In her spare time, she likes baking, playing indie video games, learning to code, playing the viola (not the violin!) and the piano. She thinks that science communication is an important skill to have, particularly now with the impending rise of fake news and misinformation.

Traps in Organic Semiconductors

Organic semiconductors are organic (carbon-based) materials that can conduct electricity. Their ability to sustain deformation without affecting its conductivity makes them the ideal choice for flexible electronics, thus enabling seamless human-device design interface, opening up various applications in healthcare, the internet of things, and information processing. However, despite their potential, the performance of these organic electronics is still not on par with devices made of inorganic semiconductors. In this lecture, we introduce some organic electronic materials, as well as their benefits and their current limitations. One such drawback is the prevalent presence of charge carrier traps, which is virtually unavoidable in organic semiconductors. Traps can capture and retain charge carriers, preventing them from being involved in the conduction of electricity, thus acting as a hindrance to an efficient charge carrier transport. We attempt to remedy this issue by adding dopants to the material, thereby filling the trap states. The addition of dopants has been shown to lead to a higher electron current for our chosen material. We believe this increase in electron current will lead to the fabrication of more efficient organic electronic devices.

3rd place - China

Juncheng Fan

Juncheng Fan is a graduate of BEng in Polymer Materials Science and Engineering from Queen Mary University of London and an incoming MPhil student in Micro and Nanotechnology Enterprise at the University of Cambridge. Juncheng has been participating in many research projects during his undergraduate years, focusing on improving people’s health and supporting environmental protection, including developing new materials for medical devices to improve their performance and durability. He designed a bioactive coating for orthopaedic implants that can facilitate bone regeneration and can exhibit antimicrobial ability if given certain stimuli during his undergraduate final-year project.

Juncheng enjoys intercultural communication and has been a volunteer at Queen Mary University of London Language Centre helping Chinese language learners improve their speaking skills since February 2021. During his leisure time, he always explores different kinds of food and goes hiking, and he is a shutterbug!

Polydopamine-based Antibacterial Coatings: Mussel-inspired Smart and Versatile Platforms for Orthopaedic Implants

Titanium and its alloys are probably the most popular materials for orthopaedic implants. However, titanium orthopaedic implants are vulnerable to bacterial adhesion due to opportunistic pathogens and may end up with failure. In addition, the incidence of bacterial adhesion can be exacerbated by their poor integration with human tissues. Introducing bioactive coatings on their surfaces is an effective approach to improve implants’ interactions with the human body and resistance to bacteria.

Inspired by mussels, polydopamine was found to be able to adhere to almost any solid surfaces. It possesses good antimicrobial activity, and can bond a range of chemicals to achieve many purposes like facilitating the formation of bones. More interestingly, polydopamine exhibits responsive behaviours to many in vivo and in vitro stimuli, such as pH and light. Therefore, polydopamine can be utilised to design smart platforms for more effective infection prevention for the next generation of orthopaedic implants.

UK

Mia Maric

Mia is a third year international PhD student studying Materials Science at the University of Manchester. She completed her undergraduate degree at the University of New South Wales in Sydney Australia, where she won the university medal for the top performing student in Materials Science and Engineering. Mia conducted an internship at the Australian Nuclear Science and Technology organisation, where her passion for nuclear materials and their useability within the nuclear power industry was developed. During her studies, she has been thoroughly involved in an array of outreach activities particularly focusing on equity, diversity and inclusion work. Earlier in 2021, Mia was selected to attend the global young scientist symposium where her passion for encouraging females within science and technology to pursue and excel in research related careers was enhanced.

Outside of research, Mia enjoys playing hockey, running and hiking. When not doing sports, she can be found volunteering at the local cat shelter and trying to bake the perfect chocolate chip cookie.

How do Hexagonal Materials Recrystallise?

Recrystallisation of Hexagonal alloys is extensively utilised within both industrial and research applications as a means of microstructural development and mechanical property refinement. However, the multifaceted nature of this process has meant that the mechanistic drivers for the microstructural as well as textural evolution that occurs during heating is not yet understood. Here, a range of experiments combined with computational modelling techniques have been able to highlight that the deformation imparted onto the alloy prior to recrystallisation strongly dictates its behaviour during heating.

In this study we have developed a model to correlate the deformed microstructure to the strong orientation dependent texture change that is seen in hexagonal alloys during recrystallisation. Therefore, an understanding of the relationship between deformation and recrystallisation is essential if heat assisted texture control is to be utilised as a cost-effective method for mechanical property enhancement of hexagonal alloys.

Hong Kong

Dio Brian Billi

Dio Brian Billi is a Final Year Undergraduate student studying Materials Engineering at City University of Hong Kong. Originally from Indonesia, Dio has worked on several projects including developing project prototypes for smart city applications and sustainability in protecting the environment. During his 3-year study program, he was able to complete his Final Year Project in CityU to fabricate and innovate in the field of food and material science; a prototype that holds potential in replacing plastic inner-lining in food packaging.

Currently undergoing his own entrepreneurship journey through the CityU flagship HKTECH300 program for start-ups, Dio and his team at OceanVoice HK are looking to protect the ocean environment and safeguard marine ecosystems for the future.

Apart from hunting for Hong Kong's best dessert spots and playing sports during the weekends, Dio enjoys reading fiction novels and talking with his team at OceanVoice.

Design of Edible bi-wax coating on nanocellulose-added bagasse paper for Green and Waste-reducing Food Packaging

To solve issues regarding wide use of plastics and food packaging contamination during recycling, my project incorporates widely available and bio-degradable materials to create a lightweight and sturdy paper packaging. It is composed of bagasse fibres with nanocellulose fibre addition and lined with an inner coating made of beeswax and carnauba wax. The research yielded positive results; with incorporated nanocellulose improving the tensile and flexural strength of the paper substrate packaging, and the bi-wax mixture inducing super hydrophobicity for food waste reduction and anti-frosting properties for longer shelf life.

Using characterization methods such as water contact angle tests, the ‘Lotus’ state was induced onto the waxed surface, causing food matter to slide easily and reducing food loss and microbial contamination. With further tuning of fabrication parameters and experimentation, the project shows promise in achieving a frozen or liquid-slurry food-safe packaging prototype that is environmentally safe and easy to recycle.

Russia

Ivan Perepletkin

Ivan Perepletkin is a graduate from Industrial University of Tyumen. Apart from studying, he is working as a specialist-geophysicist in the biggest scientific centre of ‘Rosneft’ Oil Company – Tyumen Petroleum Research Centre LLC, on the strategic project of geophysical exploration in North of Western Siberia (Gydan peninsula) at data interpretation direction. In his final thesis, he focused on electromagnetic methods integration together with seismic to refine the near-surface model in one of the gas-condensate fields in Eastern Siberia.

The technical aspects as well as practical results throughout the 3-year work on this project were presented in English at various scientific conferences, such as SPE Student Technical Congress (Aachen, Germany, 2019 and online, 2020), 7th SPE Annual Student Energy Congress (Zagreb, Croatia, 2020), EAGE Annual Conferences and Exhibitions (2018, 2020), XII SPE Scientific and Practical Congress ‘Oil & Gas Horizons’ (Moscow, 2020), and also published in peer-reviewed journals and proceedings. Apart from studying, since 2017, he has organized various international scientific events, such as conferences, workshops, field trips, etc. in the framework of the SEG Student Chapter team, where he used to be Vice-President and Scientific Committee Chair.

Integrated geophysical approach to clarify near-surface geological model in the permafrost zone

The presentation actualizes a kinematic inversion problem and the most competent electromagnetic methods combination (transient EM sounding and ultra-wideband georadar radiometry) for its solution – refining seismic data in the heterogeneous subsurface zone.

Given detailed theoretical review and empirical interconnections between analyzing parameters shows the complexing rationality. Considered examples of complexing sTEM with seismic data taken from Western and Eastern Siberia with different near-surface zone structure show the saturation forecast increase and correlation sTEM data with the well logging. Method has high horizontal resolution, but gives only averaged resistivity value vertically in particular horizon. Introducing the ultra-wideband GPR radiometry into a single set of methods allows neutralizing this problem and also expanding the studied electromagnetic parameters amount.

These arguments confirmed by the experimental realization while engineering-geological works. Recent technological breakthrough in ultra-wideband georadar radiometry allows already data quality increase in methods’ integrated use already in oil and gas fields’ areas introduction.

South Africa

Shane de Beer

Shane is an aspiring academic in the field of theoretical chemistry. He is currently undertaking his PhD studies at Stellenbosch University after completing his BSc and MSc studies at the University of Pretoria. His research interests include investigating the quantum mechanical behaviours of materials. During his previous studies, he explored chemical bonding using a computational approach and is now seeking to apply similar insights on the bonding in solid state materials. During his PhD, he is also learning experimental spectroscopic techniques to complement the theoretical models on the solid state. Shane has presented his work at the International Symposium on Halogen Bonding and published in the Journal of Computational Chemistry. In future, he aspires to develop theories and techniques to further investigate the quantum behaviours of materials.

Over the weekend, Shane can be found in the world of a thriller novel or enjoying the company of his two dachshunds. Otherwise, he is trying his hand at a new recipe or a new language.

Computational methods to investigate photocatalysis in metal-organic frameworks

Metal-organic frameworks (MOFs) are an increasingly important class of compounds in modern research. MOFs are able to absorb CO2 and various other gasses leading to their applications in gas purification. However, MOFs can also be utilised as catalysts. Aromatic ligands are common in MOFs which make them exceptional candidates for photocatalysis. In order to reduce the cost and labour invested in searching for photoactive MOFs, a computational approach can be followed. DFT and TDDFT models allow excited states to be studied to determine whether certain MOFs with the associated guest molecules are viable for photocatalytic reactions. The research here aims to develop the approach in order to identify host-guest pairs which are viable for photocatalysis. The hope is to provide a novel approach for designing reusable catalysts which can be applied to a wide range of reactions.

2020 - Online

2020 - Online

The World Final took place virtually on 12 November and was sponsored by Companhia Brasileira de Metalurgia e Mineração.

Winner - UK

Morgan Lowther

2nd place - South Africa

Bianca Gevers

3rd place - Australia

Anand Jyothi

Hong Kong

Wen Di Chan

Malaysia

Kai Xin Tan

Brazil

Mariana Alves Ribeiro

Russia

Andrey Polyakov

Winner - UK

Morgan Lowther

Having studied for an MSci in Natural Sciences at the University of Cambridge, UK, Morgan returned to his Midlands roots to work at the Manufacturing Technology Centre in 2016. As part of the National Centre for Additive Manufacturing, he spent time characterising the feedstocks used for metal powder bed printers. This led to a fascination with how powder, printing parameters and post-processing alter the behaviour of additively manufactured materials.

Now a final year PhD student at the University of Birmingham, UK, Morgan's research uses 3D printing to deliver antimicrobials from biomedical implants, hoping to tackle the increasing challenge of implant-associated infections. Engaging with science outreach since his undergraduate days, a highlight has been helping students become human 3D printers. In his spare time, Morgan is a (very) amateur baker, climber and badminton player

Head, shoulders, knees and microbes: 3D printing better implants

Over 100,000 joint replacement surgeries take place each year in the UK alone, accounting for 1 in 10 hospital admissions. But the prevalence of metallic implants belies that the human body is among the most challenging environments for materials design. Implants often fail not through mechanical means, but biologically, by failing to integrate with native tissues and being colonised by microbes. With the increasing prevalence of antimicrobial resistance predicted to kill more people than cancer by 2050, making previously simple surgeries life threatening, preventing implant-associated infection is a necessity.

Conventional approaches have relied on coatings and other secondary processing to modify implants after manufacture. However, in the past decade, advances in metal additive manufacturing (AM) have opened the possibility of radically new approaches to implant design and materials. How might AM simultaneously revolutionise the production of implants and help mitigate the threat of antimicrobial resistance?

2nd place - South Africa

Bianca Gevers

Bianca is a PhD student in the Department of Chemical Engineering at the University of Pretoria, South Africa. She is passionate about the environment, green technology and devising novel approaches to reduce society’s dependence on fossil fuels. Her work focuses on developing materials for renewable energy applications. She loves detail and seeks to understand the materials with which she works (currently layered double hydroxides, anionic clay) on a deeper level. As a result, she has spent most of her PhD investigating the mechanism whereby these materials interact with light and the implications of this on engineering the said materials for renewable energy applications. This has led to multiple publications and conference contributions. After completing her PhD, she hopes to pursue her research interests and (one day) head her own green technology company. When not disappearing into the ever-frequent rabbit holes of new research fields, she loves to look after her plant collection, play tennis, paint, play piano or violin, cook, bake, embroider, sew and host dinner parties.

Engineering photo-active materials for renewable energy generation

In a world where our lifestyle (unchanged) may result in self-destruction, the renewable generation of energy is ever more important. However, the development of renewable alternatives to fossil fuels is evolving too slowly to prevent some of the catastrophic effects of climate change. Many of these alternatives are based on limited natural resources and/or require large amounts of energy to produce or maintain – reducing their positive impact on the environment. In this lecture, a promising sub-category of these alternatives is explored – photo-active materials and their use in solar energy conversion. The mechanisms and applications of these materials are discussed, and their requirements and challenges explained. Layered double hydroxides – a specific class of these materials that can be produced in an environmentally friendly way – have shown promising results and exhibit potential for material engineering. These are used to illustrate the potential of the field and the challenges faced therein.

3rd place - Australia

Anand Jyothi

Anand is a design engineer at Worley, working on marine pipelines and subsea engineering. Anand did his Bachelor’s in Mechanical Engineering in India and completed his Master’s at the University of Western Australia. He was exposed to a broad range of industries during this time, including mining, wastewater management, biogas and bulk material transport. He has a passion for dancing and photography and has won competitions in the state level for both.

SSBC – Self-Regulating Suspended Biogas Collectors

The global biogas industry market is expected to double over the next decade with a value of $48.8bln (USD) by 2026. Conventional biogas capturing technologies present a number of problems such as limited access to the inside of the reactors, risk of damage to the cover that can cause complete loss of methane produced, and difficulty in retrofitting to existing open reactors. The Self-Regulating Suspended Biogas Collectors (SSBC) propose a new approach to capture gas from reactors. There are significant economic and social benefits for the Australian industry and community resulting from this new technology.

The SSBC can capture and retain produced biogas while floating on top of anaerobic lagoons or reactors. The system consists of a number of small floating biogas capturing modules that operate independently. The collectors have a system that control the internal pressures, which maintains the stability of the modules and stops them capsizing. SSBC's modular design negates the need to shut down the entire anaerobic system for maintenance. Desludging and crust removal operations of the anaerobic system have been shown to be much more accessible in contrast to current technologies. The patented SSBC method presents an opportunity for business to implement biogas energy generation with reduced maintenance costs and better production efficiency using a flexible system that can be retrofitted to current reactors.

Hong Kong

Wen Di Chan

Wen Di went to Hong Kong in 2016 to study Materials Engineering in City University. She was attracted by nanomaterials and their potential applications in a wide array of industrial sectors. After graduating, she joined Professor Lawrence Wu’s Research Group as a Research Assistant, focusing on biosensing and nanomaterials. She is currently in her first year of her PhD under the supervision of Professor Wu. Her research work involves using nanomaterials to improve the sensitivity and selectivity of biosensors. In her spare time, she plays Taekwondo Sport which she finds fun and challenging.

Molecular study on formation of multi-compartment structures by self-assembly amphiphilic terpolymer with dissipative particle dynamics (DPD) simulation

Efficient drug delivery, such as micelle and vesicles, plays a crucial role in disease treatment for cancer therapeutics. Current drug delivery research is moving from single compartment to multi-compartment structure to increase the capability of taking different drugs at one time. Dissipative particle dynamics (DPD) simulation at the molecular level was carried out to build micellar structures with more than one compartment. By monitoring the arm length of self-assembled amphiphilic star terpolymer, spherical, branched and cylindrical micelles and vesicles were obtained. Worm-like multi-compartment structures, which have a high potential for the uptake of several drugs, were obtained. Furthermore, evolution of the whole formation process can be clearly obtained and easily studied. DPD simulations have saved time and effort in developing new drug delivery mechanisms, and it is believed to be a powerful tool in driving development of the drug delivery system.

Malaysia

Kai Xin Tan

Kai Xin Tan graduated with a Bachelor’s degree in Metallurgical Engineering from Universiti Malaysia Perlis. She also holds a Diploma in Mechanical Engineering with first class honours from Politeknik Shah Alam Malaysia. She has participated in and won several medals in national and international competitions, namely iCompEx2017 (gold medal), ITEX2017 (gold medal) and Seoul International Invention Fair (bronze medal). She has been actively involved in students’ society and public speaking competitions. She loves sports in which she holds a black belt in WuShu martial arts. She has participated in several performances and a national singing competition. She enjoys singing and plays musical instruments.

Metastable phases and mechanisms in the dehydrogenation process of titanium hydride

Titanium hydride (TiH2), which is an intermediate product of titanium extraction, has great potential to be an alternative material to produce pure titanium powder. This research describes the characterisation of titanium powder after dehydrogenation using various techniques. Non-isothermal dehydrogenation up to 700°C has been carried out under a high-purity argon environment. High-temperature, in situ, x-ray diffraction and Rietveld refinement were used for characterisation. Cell parameters and phase changes that were determined through the Rietveld method proved that dehydrogenation occurs through heating. It was found that several metastable phases that shared the same crystal structures were formed during phase transformation. Lattice parameters increased under the influence of thermal expansion and reduced due to dehydrogenation. The effects of these two parameters on the phase transformation and crystal structures formed were studied. The non-isothermal dehydrogenation process had a sequence of phase transformations starting from δ-titanium to a final α-titanium phase.

Brazil

Mariana Alves Ribeiro

Mariana Alves Ribeiro is an undergraduate metallurgical engineering student at the Federal University of Minas Gerais. She studied Ferrous Metallurgy at the Montanuniversitaet Leoben in Austria and is also a Chemistry Technician. Since 2012, she has been working on mining, metallurgical and material science projects.

In 2017, she started an internship in a steelmaking group, accumulating around ten science projects, which won some academic and industry relevant awards. This included R&D around steelmaking reactors using water models and Computational Fluid Dynamics simulations. The last project has an environmental focus, using cleaner production concepts on greenhouse gases for steelmaking industry reduction. Her working passions are metals reduction and refining. In her spare time, she usually reads, watch some movies, and is now starting to do some abstract watercolour painting.

Greenhouse gas management and energy efficiency in an oxygen steelmaking plant

Carbon emissions and climate change are increasingly in focus. Several studies have been carried out on strategies to reduce the amount of greenhouse gases. According to the World Steel Organisation, between January 2019 and May 2020, 148,775,000t of steel were produced worldwide, demonstrating the expressiveness of the steel industry. Management of greenhouse gases must be carried out to reduce carbon dioxide emissions.

This presentation approaches the management of greenhouse gases for an oxygen steelmaking plant, under the standards of the Brazilian GHG Protocol. According to the results, carbon dioxide emissions in the melt shop have been reduced by 92% over the years. Pig iron consumption and gas recovery are variables with the largest impact on greenhouse gas emissions.

Russia

Andrey Polyakov

Andrey is a postgraduate student in the metallurgy department at Saint Petersburg Mining University. Before entering the postgraduate programme, Andrey received his Master’s degree at the School of Non-Ferrous Metals and Material Science in Krasnoyarsk, where he was part of a research unit involved in developing

high-amperage aluminium reduction cells. He continues his work dedicated to increasing energy efficiency and stability of aluminium electrolysis through designing new technological solutions. Andrey thinks that the sustainable production of aluminium is of great importance due to its constantly growing production rate and, as a result, environmental impact. Andrey likes to spend his leisure time playing the guitar, meeting his friends and travelling.

Primary aluminium production – how the wettability of carbon anodes influences energy efficiency

In 2019, almost 64Mt of primary aluminium were produced, exceeding the 2010 indicators by 40%. Primary aluminium production requires a huge amount of electrical energy, which is the reason why world producers apply much effort to reduce specific energy consumption. Due to the serious environmental issues the world is facing today, it is vital to use energy and resources sustainably. This lecture introduces aluminium reduction technology and ways to improve the energy efficiency of this process. It highlights the phenomena observed during the anode process – one of the most important parts of aluminium electrolysis – and how the wettability of carbon anodes influences the anode process and its connection to specific energy consumption. The presentation also discusses existing and potential technical solutions to improve the interaction between carbon anodes and cryolite-alumina melt, hence the energy efficiency.

2019 - London, UK

2019 - London, UK

Winner - South Africa

Tamlyn Naidu

2nd place- Malaysia

Jia Yong Lam

3rd place - Canada

Morgan Lehtinen

Brazil

Tiago Dos Santos Junior

Australia

Michael Max Brown

Singapore

Chuah Chong Yang

Hong Kong

Franklin To

Russia

Suleiman Khusnutdinov

Winner - South Africa

Tamlyn Naidu

Tamlyn is a PhD student in the department of chemical and metallurgical engineering at the University of the Witwatersrand in Johannesburg, South Africa. She has spent most of her postgraduate degree involved in water rehabilitation and waste beneficiation projects, aiming to promote sustainability in the water space. She is part of the Industrial and Mining Water Research Unit and is also affiliated with the Center of Water Research. She believes that the failure to address the unsustainable use of water now will mean greater struggles in the future to achieve goals in a myriad other areas. Outside of school she is an avid cat enthusiast, food eater and movie watcher.

Acid Mine Drainage remediation system using waste products from the steel manufacturing and sugar industries

According to the United Nations, Acid Mine Drainage (AMD) is classified as the second biggest environmental problem facing the planet, due to the amount produced worldwide as well as the high cost of treatment. Cost-effective remediation methods are thus strongly needed. The operation of a waste-beneficiation treatment scheme incorporating the use of two waste products; steel slag and sugarcane bagasse, is one such method. These products produced in many AMD-affected areas, can raise the pH of the AMD, enabling metal removal through precipitation and promoting sulphate removal through biological reduction. The slag is valorised through this process; hereafter being used in construction applications. The study confirmed the potential of these products in AMD treatment through a two-step chemical and biological process. Optimisation of the process could result in low cost AMD pre-treatment, or as a way for mines to recycle their acid water for use as process or agricultural water.

2nd place- Malaysia

Jia Yong Lam

Jia-Yong is a second year PhD student in the Faculty of Medicine and Health Sciences at Universiti Putra Malaysia. His doctoral research focuses on the development of biosensor to improve the current diagnostics for leptospirosis, an often neglected disease, but of global importance. He completed his Bachelor's degree in biomedical science at Universiti Tunku Abdul Rahman, where he studied on genetic polymorphisms associated to nasopharyngeal cancer in his research project. He also holds a Master's degree in molecular medicine and bioengineering from National Chiao Tung University, Taiwan. During his Master's studies, he worked on the discovery of antivirals against dengue virus from natural products. He was awarded honorary membership of the Phi Tau Phi Scholastic Honour Society of the Republic of China for his academic achievements during his two-year stint in Taiwan. Having worked on various scientific fields in his researches, he believes that a multidisciplinary approach in research is the key for a more creative and ground-breaking solution to a problem. Outside the lab, Jia-Yong is an avid home cook and a food enthusiast. To him, doing research is like cooking; you need to plan, get the right materials, optimise the method, enjoy the outcome and finally do the cleaning.

DNA biosensor based on optical fibre for the detection of pathogen: A novel approach

Silica-made optical fibres transmit light through the total internal reflection principle and were originally intended for the use in communications. However, studies eventually discovered their biosensing potential. When light is propagated through the fibre, a portion of the light penetrates the fibre wall into the surrounding medium, recognising the different refractive index in the evanescent field. Thus, immobilising biological recognition elements at the surface allows for the detection of the specific analytes. Tapered optical fibre utilises the special geometries of the fibre to enhance its biosensing potential.

This presentation describes the development of a tapered optical fibre DNA biosensor for the detection of Leptospira DNA, a pathogen responsible for a globally important disease, leptospirosis. Optical fibres are tapered and functionalised by immobilising a DNA capture probe on its surface. The research findings show that the biosensor demonstrated good sensitivity and specificity for detecting Leptospira DNA, and has great potential to be developed into a new model of diagnostic.

3rd place - Canada

Morgan Lehtinen