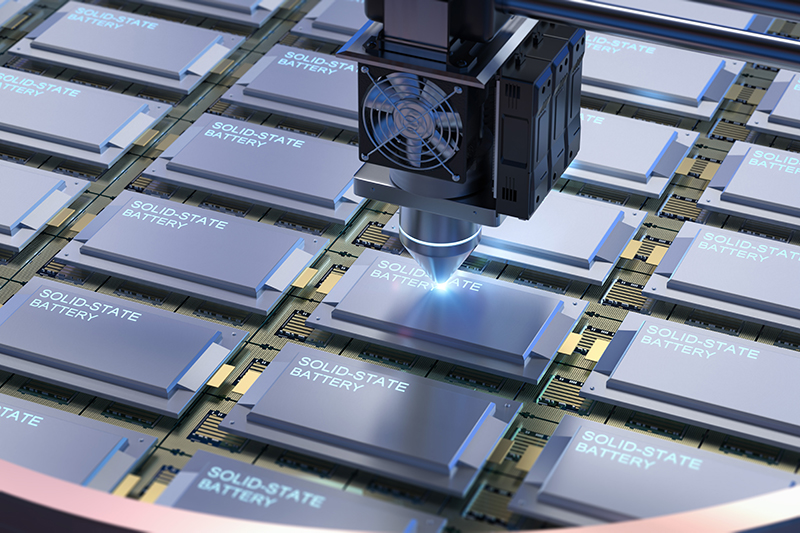

Solid electrolyte battery materials

A patent for a solid electrolyte material for secondary batteries used for energy storage.

Secondary or rechargeable batteries have an important role to play in the global transition towards more sustainable sources of energy. Not only can batteries be used to power consumer devices, large-scale batteries can also be used to store renewable energy for load-levelling and maintaining the stability of electricity grids.

Much work is therefore ongoing to develop improved battery designs, as well as new and optimised materials for electrodes, current collectors and electrolytes.

An important class of secondary batteries are those that use a solid electrolyte to provide ionic conduction between electrodes.

Solid-state batteries can, in principle, provide a higher energy density than devices using liquid or gel polymer electrolytes. Solid electrolyte lithium-ion batteries, in particular, are also less flammable, and so safer to operate, than their liquid-electrolyte counterparts, which typically contain volatile organic solvents.

However, manufacturing solid-state electrolyte materials that can balance high lithium-ion conductivity, volumetric energy density and power density with reliable physical and chemical stability is not straightforward.

Various types of materials have been proposed, including inorganic solid electrolytes (such as oxides, sulphides, phosphates, nitrides, hydrides and halides) and solid polymer electrolytes (i.e. solvent-free salt solutions in a polymer host matrix).

While inorganic solid electrolytes tend to achieve higher ionic conductivities, they can also suffer from problems with stability. For instance, sulphide-based solid electrolytes have a tendency to decompose on exposure to air, forming hydrogen sulphide. Moreover, some halide-based electrolytes undergo structural phase transformations within the standard operating temperature range of batteries (-30°C to 80°C).

Recently, however, Panasonic Intellectual Property Management Co. Ltd. (an IP subsidiary of Panasonic) has been granted European Patent EP3736830B1, entitled Solid Electrolyte Material and Battery. This describes halide-based solid-state electrolytes combining high ionic conductivities with structural stability at typical battery-operating temperatures.

In particular, the patent claims protection for a material represented by the compositional formula Li₃YX₆, where X is two or more kinds of elements selected from the group consisting of chlorine (Cl), bromine (Br) and iodine (I).

Protection is also claimed for a battery in which at least one of a positive electrode, a negative electrode and an electrolyte layer includes this solid electrolyte material.

According to the patent, electrolyte materials falling within the claimed definition exhibit room-temperature lithium-ion conductivities at not less than 1x10-4 S/cm, are stable under typical battery-operating conditions and avoid the use of sulphur.

The inventors posit that the advantageous properties of the claimed material result from its crystal structure. In particular, the underlying crystal structure is believed to be that of LiX (where X is two or more kinds of elements selected from Cl, Br and I). This structure is then modulated by doping with Y3+ cations which, due to their differing valence from Li+, induce the formation of vacancies. Lithium ions can be conducted rapidly through the vacancies in the crystal structure.

The patent includes various experimental examples that highlight the advantages of the claimed electrolyte. For instance, some of the examples illustrate specific compositions that achieve ion conductivities as high as 21.7 x 10-4 S/cm (Li₃YCl₄BrI), or 33.0 x 10-4 S/cm (Li₃YCl₂Br₂I₂) at room temperature, without exhibiting any phase transitions up to 80°C.

In contrast, compositions falling outside the claimed invention (such as Li₃InBr₆ and Li₂FeCl₄) exhibit ion conductivities that are orders of magnitude lower, and some (such as Li₃InBr₆) undergo a phase transition, indicated by a sudden change in conductivity as a function of increasing or decreasing temperature.

Preferred compositions claimed in the patent include Li₃YBr₆-xClx (where 0.5 ≤ x ≤ 5.5), Li₃YBr₆-xIx (where 0.5 ≤ x ≤ 5.5), and Li₃YCllBrmIn (where l + m + n = 6).

The inventors explain that the claimed solid electrolyte material can be produced by blending binary halide raw material powders to a target composition, and then subjecting the blend to mixing and grinding using a mechanochemical milling method, or mixing followed by sintering in a vacuum or inert atmosphere.

The resultant material can be provided in the form of particles (which may be acicular, spherical or elliptical), pellets, or a plate shape formed by pressurised particles, and it may include a crystal phase or an amorphous phase.

According to the patent, the material can be used in the positive electrode, negative electrode or electrolyte layer. Experimental examples are included that show how secondary batteries including both a positive electrode and electrolyte layer incorporating this material achieve significantly higher initial discharge capacities than comparative example batteries that use Li₂FeCl₄ as the solid electrolyte material.