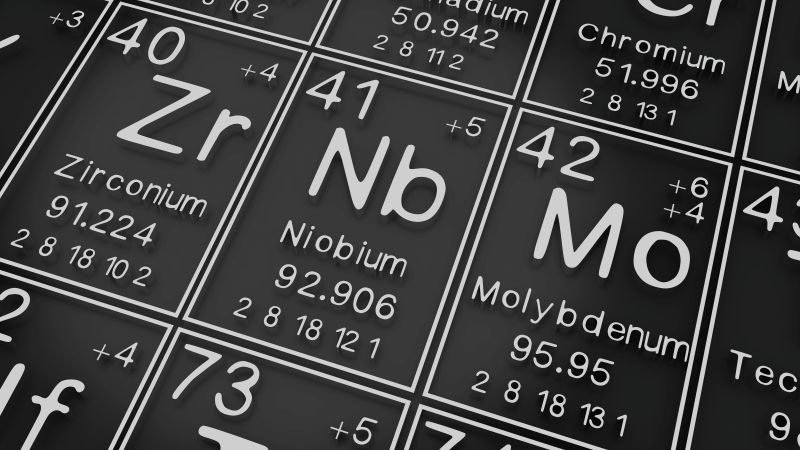

Boosting future supply of niobium

University of Birmingham, UK, and Brazil-based CBMM, partner to improve production and reduce the cost of niobium compounds.

Niobium, though non-critical, is rare and an important metal and essential component for carbon recycling technology.

The project is related to a technology that uses niobium-based perovskites to turn the CO₂ emitted from industrial processes into carbon monoxide (CO), which is then fed back into the process, creating a closed carbon loop.

The niobium-based perovskite has a 100% selectivity for CO production, meaning CO₂ passing through the material is transformed only into CO.

This type of perovskite was used when Birmingham researchers modelled an adaptation for existing blast furnaces to reduce steel-making emissions by up to 90%.

An advantage of this closed-loop carbon-recycling approach, say researchers, lies in its applicability to retrofit existing industrial processes, facilitating large-scale adoption and minimising the stranded assets.

Birmingham also claims the perovskite technology operates at a lower temperature compared to conventional alternatives.

It is hoped the outcomes will help advance commercialisation of the decarbonisation technology through PeroCycle, a spin-out backed by the University of Birmingham and Anglo American, with venture-building led by Cambridge Future Tech.

CBMM's involvement will ensure the necessary support for future scalability of niobium-based perovskite production.