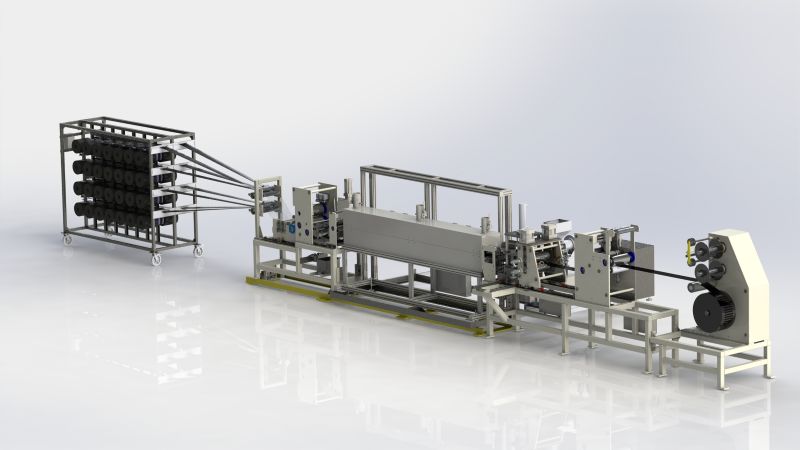

UK's first open-access, fibre-reinforced, thermoplastic tape capability

The Advanced Manufacturing Research Centre (AMRC) claims it will accelerate innovation in sustainable composites.

The hybrid line will be installed at the AMRC’s Factory of the Future facility, where businesses and researchers can develop new processing methodologies for thermoplastic composite intermediate tapes on a small industrial scale with support from the AMRC.

The line and tape slitter will be installed towards the end of 2025 and will operate from early 2026.

The research platform will feature a dual-mode thermoplastic processing line, designed and built by fibre handling and converting technology specialist Cygnet Texkimp of Northwich, UK, to provide direct melt and slurry-based processing capability for a wide range of polymers and applications.

The line also incorporates Cygnet Texkimp’s Flatline creel and fibre spreading technologies, which AMRC says is aimed to maximise the range of fibres that can be processed, and to facilitate the development of new composite tapes for downstream processing into composite components for industry.

The AMRC states the dual-mode line allows industrial-grade polymers such as polypropylene, nylons and PEEK to be processed from pellets using Cygnet Texkimp’s direct melt impregnation technology, or powdered polymers to be processed using water-based slurries.

The AMRC says the line is modular in design and allows rapid conversion between these two operating modes.

The integration of Cygnet Texkimp’s Flatline creel and fibre spreading technologies enables processing of a range of fibres, including carbon, glass, recycled and natural fibres.

It can also be configured to produce composite tapes in a variety of widths from 45mm up to 180mm, and with a specific fibre and polymer weight per metre.