Matthew Thornton

Commercial Manager , The Bridge University of Lincoln

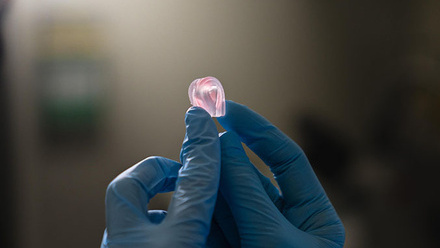

Prior to joining the University of Lincoln as the Commercial Manager for The Bridge in February 2023, Matthew was the Chief Innovation Officer for Polymateria Ltd based in London, where he was responsible for new product development in partnership with commercial customers to ensure that the companies research is commercially focussed and meets the requirements of our customers to deliver value for the business in the short, medium, and long-term, with a focus on strategic direction and innovation.

Matthew has a BSc (Hons) in Chemistry with Chemical Engineering from the University of Huddersfield, UK (2001) and a PhD in Materials Science and Engineering from the University of Nottingham, UK (2005). Following his studies Matthew spent 18 months as a KTP Associate at the University of Reading, researching novel materials for the removal of mercury from crematoria flue gases, before spending 7 years at the Institute of Materials, Minerals and Mining as both a Materials Advisor and the Polymer Sector Leader for the Materials Knowledge Transfer Network. He joined NetComposites Ltd in August 2013 as a Project Manager and was responsible for the management of several UK Government and EU funded collaborative research and development projects. In April 2016, Matthew joined Haydale Composite Solutions as UK Site and Innovation Director and was responsible for both the Haydale Group Innovation Department and the Resins, Polymers and Composites Business Unit.

Matthew is a Fellow of the Institute of Materials, Minerals and Mining, a Chartered Environmentalist, and a Leadership Team Member of both the Elastomer Group and the Polymer Group of the IOM3. He has a Postgraduate Diploma in Business Administration from the Open University, UK (2022), and is the Secretary-General for the International Rubber Conference Organisation.