An elastomer-based 3D ink can be stretchy and rigid

An elastomer-based ink for 3D printing objects with locally changing mechanical properties negates mechanical joints, say inventors at EPFL, Switzerland.

A team from the Soft Materials Laboratory at EPFL have developed 3D-printable, double network, granular elastomers (DNGEs), which they report can vary their properties to an unprecedented degree.

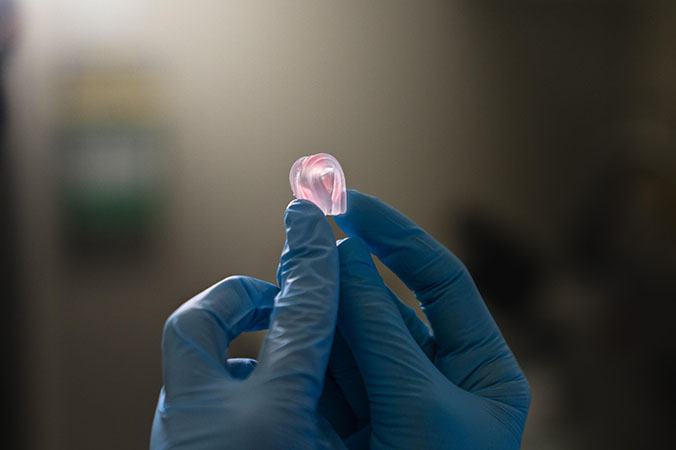

PhD student Eva Baur has printed a prototype 'finger' with rigid 'bones' from DNGEs. The finger deforms in a pre-defined way, demonstrating the technology's potential to manufacture devices that are sufficiently supple to bend and stretch, while being firm enough to manipulate objects.

The key to DNGEs' versatility is in engineering two elastomeric networks, reports the team.

Elastomer microparticles are produced from oil-in-water emulsion drops and these are placed in a precursor solution, where they absorb elastomer compounds and swell up. These are used to make a 3D printable ink, which is loaded into a bioprinter to create a desired structure. This is polymerised within the structure to create a second elastomeric network that makes the entire object rigid.