NCC reveal new automated fibre placement-automated tape lay up tool

National Composite Centre's new system intended for medium to large scale manufacturing.

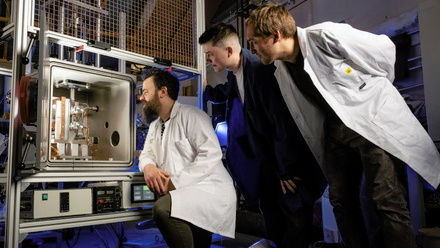

The National Composites Centre, UK, has unveiled a new Automated Fibre Placement-Automated Tape Lay Up cell.

The cell, created in partnership with Electroimpact, UK, combines both AFP and ATL in a single system. The dual system can be used individually or together to collaborate and create large, complex structures with minimal downtime. The robot is intended for medium to large scale manufacturing with high performance and accuracy robotic motion platform.

The AFP process head utilises x 8 tows, each measuring 12.7mm wide, with either an infrared heater to manufacture thermoset composites, or the novel humm3 flash technology, developed by Heraeus Noblelight Ltd., UK, and tested at the NCC for to manufacture thermosets of low temperatures (30-60°C) and high temperature thermoplastics or bindered dry fibre (100-300 °C).

The ATL head can deposit tapes of 75, 200 or 300mm widths using the same heating systems and material processing capability as AFP.

Vertical and horizontal rotators allow for complex tools to be used to create geometries such as convex and concave panels, large scale diameter pipes, spars or barrel/tower structures. The rotators enable components of up to 4.6m diameter, and 7m in length to be manufactured. The cell's flat tables also allow for smaller scale analyses such as material testing or prototype trials to de-risk programs and build knowledge prior to larger scale projects.

Eva Sastres Collardo, Automation Manager at the NCC said, ‘The NCC's AFP-ATL capability is a perfect test bed for automated composite manufacturing at a medium to large scale level. The system will enable new and existing markets to build up their innovation platforms from the ground up, from small scale prototyping and material testing through to full scale demonstrators and data analytics. The output for customers will be the enabling of high-performance products, created at high volume with reduced cost and waste to achieve step change technology in their field.’