Test facility to combat space junk

A Glasgow basement facility will test the structural integrity of materials 3D printed in space.

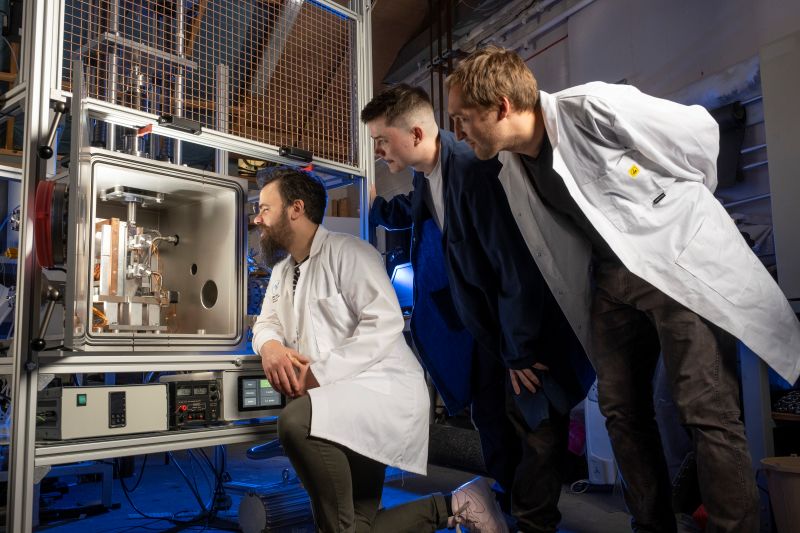

Researchers at the University of Glasgow’s James Watt School of Engineering have built the NextSpace Testrig in partnership with The Manufacturing Technology Centre, supported by £253,000 from the UK Space Agency.

The facility uses a specially-constructed vacuum chamber capable of generating temperatures between -150°C and +250°C to create space-like conditions on Earth.

Space manufacturing aims to radically change how objects and materials are sent into orbit. Instead of carrying complete devices like solar reflectors into space on rockets, specially designed 3D printers could create structures more cheaply directly in orbit instead.

Several experiments have already sent prototype 3D printers into orbit, and metal parts have been 3D printed by astronauts aboard the International Space Station.

Previously, no research facility has been dedicated to ensuring polymers, ceramics and metals printed in orbit can withstand the space’s extreme physical strains.

The testing facility features a unique magazine system that can autonomously test multiple samples in a single cycle, reportedly making it more efficient than traditional testing methods.

The system can apply up to 20 kilonewtons of force (equivalent to 2,000kg) to break samples and analyse their properties in the vacuum conditions it can generate, as well as subject samples to cycles of extreme temperatures.

Imperfections such as tiny bubbles or poorly melted sections that might be inconsequential on Earth can behave differently in space.

Such flaws could cause 3D-printed objects to shatter, scattering dangerous fragments into orbit as ‘space junk’.

Dr Bailet says the NextSpace TestRig is open to academic colleagues, researchers and commercial clients from around the world, with the aim to help them ensure any materials they plan to 3D print in space will work safely.