Goodbye one and all

Fred Starr FIMMM pens his final column for Materials World.

In future, certain readers will no longer be choking over their breakfast cornflakes, when they get to Fred Starr’s latest strictures on nuclear energy. Or, these days, do they hurl the laptop through the conservatory windows?

This is, in fact, the very last of Fred Starr Recollects. Notwithstanding, I cannot leave nuclear, which brought me a gold medal from the Institute, without a final line on the subject. Within the last month, I heard one of the apologists for nuclear power state, without a trace of embarrassment, that our Small Nuclear Reactor will have an output of 470MW – in real money, enough to power Manchester. This is a long way from what was initially floated, where it seemed there would be a reactor in every neighbourhood, giving us district heating as well as electricity.

Why am I handing in my cards, so to speak? When I began work, fossil fuel power generation, nuclear, heavy engineering and the aircraft sector were supreme. Times have changed. We have renewable power, and modern life and communications reflects its dependence on the manipulation of materials at the atomic scale. At some point, we will have to switch to plastics that biodegrade. Materials World needs to be in the vanguard of the revolution, not held back by moaning antediluvians.

Change in life

Moreover, my adventures as a metallurgist were on the wane by the 1980s. Anecdotes from the following years wouldn’t be of much interest. But for me, the change was adventitious, opening up the Continent, North America and New Zealand. It eventually landed me a retirement job at the EU’s Energy Centre in the Netherlands. While there, I did the basic design for a carbon capture, coal-based plant, making hydrogen and electricity. It then seemed the hydrogen economy was just around the corner. I now know it’s vastly over-hyped. Like nuclear once was.

My switch from metallurgy began when British Gas (BG) pulled the plug on coal and oil gasification. It was the biggest mistake ever made in the British energy sector. If BG had kept on with its supremely successful programmes, the British chemical engineering sector would have been five times the current size, we would have been building our own industrial gas turbines, and the British would be world leaders in carbon capture and storage. The Miner’s Strike, which still blights the North, would have been completely unnecessary.

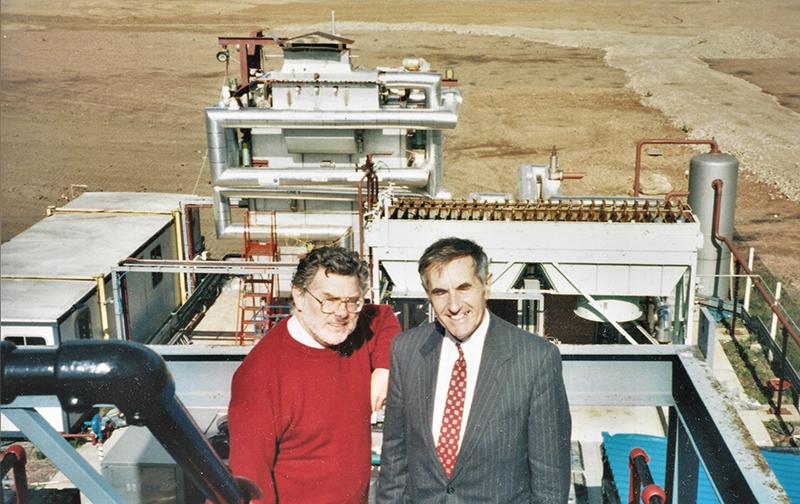

That is in an alternate universe. At BG, I was encouraged by Grev Gibson, an Assistant Director where I worked, to come up with proposals where gas was to be used as a fuel for generating electricity. So was born the idea of advanced gas turbines, initially based on molybdenum, which we had found was the only material resistant to corrosion in gas hydrogenators. In retrospect, my early ideas were pretty naïve. But I eventually arrived at the closed cycle gas turbine, a concept that had legs enough to build a demonstrator. The picture above shows Grev and myself looking over the plant. It boasted the world’s highest temperature metallic heat exchanger, and the fi rst ever high-temperature, printed, circuit heat exchanger.

The perils of Stirling Engine Domestic CHP

Technical arguments can get heated, but the only time I saw a delegate punching a lecturer was at a Stirling Engine Conference, after the Q&A session began. It was explained to me, by a fellow attendee, that the Stirling Engine was, eff ectively, a cargo cult to some individuals, and one needed to be careful with what one said.

The Stirling Engine, which had been kicking around as a never-quite-made it prime mover since 1850, was crying out for novel high-temperature alloys – giving scope for our team of metallurgists. Through good contacts and fortunate accidents, our ideas evolved into ‘Stirling Engine Domestic CHP (Combined Heat and Power)’. The idea was to incorporate a Stirling Engine driving a kilowatt-sized generator within a modifi ed gas boiler. When hot water was needed for washing or for heating radiators, the engine would fi re up, generating electricity. The power would be used in the house, but any surplus would be sent back though the mains to be used by some other household. The hot water came from the engine cooling system. Domestic CHP promised to extend the life of Britain’s gas supplies, as almost all the energy was usefully used.

Starr’s rules of invention

Our Stirling Engine CHP project was sneered at, until mass redundancies hit a privatised BG – domestic cogeneration, to give it the more general name, became a lifeboat where everyone wanted to climb aboard. The programme gradually slipped away from me. Nevertheless, as the originator, I would be the fall guy when things went wrong. It seemed advisable to take the golden handshake of redundancy and move to an organisation where I would be more appreciated.

However, in my last years with BG, I had to deal with many outfi ts promoting equipment potentially useful for domestic cogeneration. From this, I formulated the 30-30-40 rules in weighing up the truth of their claims. Here they are:

1. 30% is true

2. 30% is true but doesn’t apply to what is offered. Whether the inventors know this or not is arguable

3. 40% is lies

Experience is knowing in which category to put the assertions. Works for politics too!

Finally, I would like to thank the readers who have stayed the course, and especially those who have taken the time to make contact. Then there are the editors who have given unfailing assistance, and Katherine Williams (IOM3 Head of Content) who thought of Fred as a columnist, way back in 2012.