By design

Reducing the demand for critical materials

Unprecedented amounts of primary materials mined around the world are needed for the components and infrastructure underpinning the technological transformations involved in digitalisation, electrification and the energy transition.

Current geopolitical uncertainties bring the vulnerability of these critical materials supply chains to the fore.

The US and EU are prioritising self-sufficiency to varying degrees with different approaches. The UK, like many nations, has few domestic critical material resources and little strategic manufacturing capacity. There is therefore a growing list of minerals deemed critical to the UK economy and at risk of supply shortage.

The UK Government is appropriately concerned about future supply shortages, which could dramatically increase costs and disrupt the delivery of infrastructure and technology innovation as demand outstrips supply.

Beyond the economic incentives, we must also address the significant environmental and ethical concerns.

The core issue is resource extraction and consumption, which is a primary driver of the ‘triple planetary crisis’ of climate change, biodiversity loss and pollution. Simultaneously, domestic and international resource use continues to increase.

Yet our policy focuses only on one side of the equation, by working to secure a larger supply of these minerals through trade deals, and encouraging mining companies and the nations where they operate to increase extraction.

There is little focus on how we can use less material in the first place, find alternatives, and reuse and recycle them domestically. The potential consequences of supply chain failures mean we cannot afford to wait for market signals to change our design practices. Government, engineers and designers all have a duty to avoid harmful and self-destructive patterns of resource use.

Taking lithium as an example – if we reduce the size of the UK’s larger electric vehicle (EV) batteries by 30%, we could cut our lithium demand by 17%. This would save 75Mt of rock mined for lithium by 2040 – the equivalent of 19 Wembley Stadiums full of rock.

Many alternative design approaches can reduce demand for critical materials, including:

- Material substitution – where a critical material can be replaced by a more readily available alternative with similar properties. Sodium-ion batteries, for example, are being developed that could replace lithium-ion batteries in future, using more abundant sodium. However, sodium-ion batteries have lower energy efficiency and some require other critical materials such as nickel and manganese, highlighting the need for continued innovation in developing substitutes.

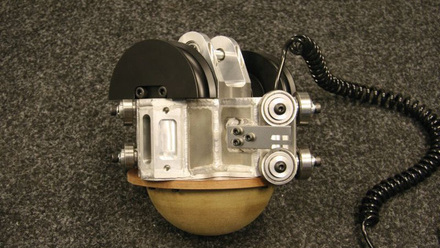

- Designing for repair/life extension – where products or infrastructure are designed for durability, modularity or repairability. Electric vehicle batteries in China are designed to be removed and swapped out for fully charged ones at charging stations.

- Designing for reuse – such as reusing lithium-ion batteries from EVs for electricity storage in solar energy systems with appropriate planning and design.

- Designing for recovery and remanufacture – design for disassembly can help overcome barriers and allow greater recovery of critical materials at end-of-life, by reducing time and cost of disassembly and simplifying the recovery process.

However, currently there are few incentives and often active disincentives to reduce critical materials use in any given design process. For example, epoxy glues in wind turbines hinder disassembly and recovery of rare neodymium magnets at the end of the turbine’s life.

The first step is to create incentives for efficiency. Long-term management also requires clear data on the composition of key technologies, which we currently lack.

The government should adopt a broader materials strategy to monitor the stock levels, sustainability, ethics and supply chain risks of materials on a national level. Engineering education and skills are also crucial to putting more sustainable design into practice.

The National Engineering Policy Centre (NEPC) commissioned a Review of sustainability teaching in UK engineering higher education. It found sustainable design was far too often treated as an 'afterthought in the design process – something that is checked for compliance at an advanced stage of the design rather than an innate consideration at every stage'.

Similarly, the Design Council reported in 2024 that less than half of UK designers feel they have the skills to meet the demand for environmental design. Incorporating training on resource efficiency and global sustainability would better prepare engineers to reduce short-term critical material demand, and enable cheaper and easier materials recovery in the long term.

Taking these steps also presents the UK with an opportunity to show economic and environmental leadership.

Without a radical change in approach, the UK risks playing catch-up behind the nations and businesses that are improving their materials resilience now.

The NEPC’s full report on Critical materials: demand-side resource efficiency measures for sustainability and resilience, supported by IOM3, can be found online.