A digital strategy for materials

A joint workshop between IOM3 and the British Standards Institution discussed a strategy for the digitisation of the materials sector. Dr Norman Swindells CEng FIMMM, Managing Director at Ferroday Ltd, UK, reports.

The increase in digitisation in engineering and manufacturing is creating new demands and new opportunities for the digital representation of materials information for procurement, design, service, recovery and re-use. Objectives described by words such as ‘interoperability’, ‘big data’, ‘smart manufacturing’, ‘Industry 4.0’ and ‘digital twin’ are in frequent use, often without explaining what they mean or how they can be implemented in practice. A global collaboration between most industrial nations, active since 1984, is responsible for a technology based on international standards for the specifications of how to represent digital industrial data to achieve these objectives.

A joint workshop between IOM3 and the British Standards Institution (BSI) Committee AMT/4, held on 5 December 2019, discussed a strategy for the digitisation of the materials sector and is the start of a process to explore what these developments mean for the materials sector. The context for the workshop was a UK national policy for the greater adoption of digital methods, as described in the Made Smarter Review 2017, and a new UK Industrial Strategy under Transforming the Foundation Industries.

The workshop began with a series of short presentations to describe successful applications of the international standards for the digital representation of engineering information and to provide background for the discussions around a digital strategy for the materials sector.

A presentation by Matthew West of Information Junction Ltd emphasised the national importance of the strategic value of digital information and described the efforts being made to create a digital twin for the whole of the national infrastructure. A key remark was that the management of information should have the same importance as the management of money. Both have value and are essential for the wellbeing of a company and its future.

The importance of standard digital information models in managing the complexity of new products and services was described by Karl Devilliers of Airbus. Airbus requires end-to-end overall optimum interoperability, dedicative views, capability for the re-use of information, and collaboration across functions within their supply chain and with their customers. The Association of Aerospace and Defence Industries in Europe has identified a backbone of standards to enable cross-domain interoperability in the aerospace and defence product lifecycle.

A presentation on ISO 8000 Data Quality from Tim King, Babcock International Ltd, emphasised that the concept of quality described in this standard is the same as engineering quality – that is, conformance to a specification.

ISO standards

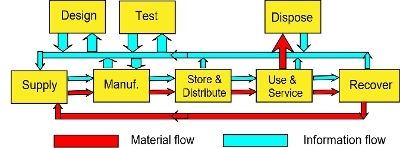

International and regional standards underpin the successful growth and exploitation of mobile phones, graphical and image representations, and many other aspects of the application of modern IT systems. The digital representation of engineering and manufacturing information is no exception. The figure opposite illustrates that there is a flow of information along the product lifecycle in parallel with the flow of material. Specifications based on standards are used to manage the flow of the materials and now standard specifications can manage the digital flow of the information.

Product data

ISO 10303 Product Data Representation and Exchange is the family of international standards that specify information models for the computer-interpretable representation, exchange and archiving of engineering product information, independent from proprietary software. The technology presented in the standards is developed by ISO TC184/SC4 Industrial Data and is known informally as STEP – Standards for the Exchange of Product Data. ISO 10303-1 provides an overview of the technology and specifies the fundamental principles of ISO 10303.

The STEP technology is developed in a global collaboration by most industrial nations and is supported by the main players in aerospace, automotive, process plant, oil and gas. The standards are reviewed and updated frequently to align them with modern systems and practice. The BSI Committee AMT/4 is the UK mirror of the ISO Committee, and many of the most important standards have been developed here.

STEP addresses two problems for digital engineering:

- Interoperability – different computer software systems in the design and manufacturing processes and in the supply chain need to be able to interpret and to process the information that they receive from other systems.

- Sustainability – digital engineering data has to be maintained to still be usable in this form for many years when the originating software is no longer available.

The specifications in ISO 10303 standards describe the digital representation of geometry and topology, processes, properties, dimensions and tolerances, composition, etc. The specifications for applying STEP to specific aspects of engineering are called Applications Protocols (AP). Each AP is a specialisation of a generic core digital model for the representation of all relevant product data, and so the same concepts should have the same digital representation in all applications.

These specifications can also form the basis for the quality control and quality assurance of the digital engineering data, just as with any other engineered product. ISO 8000 Data Quality is also developed by ISO TC184/SC4. Note that the data values are not standardised, only the semantics and the syntax of the digital representation are specified.

Following protocol

ISO 10303-45 Materials and Other Engineering Properties is one of the generic core models of STEP that defines a material property as a type of property of a product where the meaning and value of the property depend on the method and conditions by which it was measured – the concept of the dependent data environment. First published in 1995, subsequent editions of ISO 10303-45 have extended the types of property value to include mathematical values and extended the dependencies to include the product dimensions.

The Application Protocol ISO 10303-235 Edition 2 Engineering Properties and Materials Information (AP235) extends ISO 10303-45 to describe the product, its history, composition and internal structure, together with the processes, their properties and the resources used in measuring the property value – with additional capabilities such as tolerances, locations and the representation of property values as mathematical expressions. The information model in AP235 is built from the relevant generic models that are used in the rest of STEP.

Materials information is therefore digitally represented in the same way as the representations of engineering product data that are already in use in the main industrial applications of other STEP standards. STEP standards can therefore provide a complete description of a product in a computer-understandable form that is independent from proprietary software. An illustration of the scope of ISO 10303-235 to represent some aspects of the characterisation of a product is shown in the diagram overleaf.

AP235 was originally developed to meet a business need by aerospace for a traceable audit trail showing the origins of material property data values used in a design, particularly for a part that failed in service. The resulting standard has a wider capability to represent all of the data for any property of a product resulting from a process, such as a testing method or manufacturing process. The whole product lifecycle can be represented, and this collection of information can be digitally traceable.

Integrated workflow

These ISO standards could provide new opportunities and business models for the application and presentation of materials information. A rigorous management of digital information should have high priority in any company’s business and the standards described here can support the tools to achieve this objective.

An important benefit from digital specifications based on common information models is that several standards can be combined to provide opportunities for new business models and new methods of working. Several have been combined to form an integrated system for manufacturing by machining, for example.

A 3D CAD model of a part forms the basis for the design of the tool path. This tool path is the basis for the machine control instructions. Data on the assembly of the cutting tool and its exact dimensions can improve the tolerances and avoid collisions. These STEP standards have then been integrated with other standards for the output of the machining data and the quality assurance of the result to provide a digital twin of the machining process. AP235 could provide more opportunities to integrate materials information into digitally controlled machining and other manufacturing processes.

Big data is a common theme for a new opportunity in the new digital era, but it comes with constraints and is characterised by

the following:

- Variety – the collection of data arises from several sources

- Velocity – the speed with which the data can be generated poses problems for its management

- Variability – inconsistencies in the data can hamper its combination

- Veracity – the quality of the data can vary, and this will influence the reliability of the outcome

- Complexity – if the data comes from different sources, then they have to be able to be combined in a way that enhances the value of the whole collection

It is this last point that controls the whole feasibility of the Big Data theme. There is an obvious benefit from a standardised representation that defines the same semantics and syntax for each item of information to be combined.

For the development and exploitation of new materials, new users will need full information to have confidence in their use for new applications. This information will be generated in many different locations and will not be confined to simple properties. AP235 provides the resources that would enable information on new materials from different sources to be represented by the same specification and to be collected together.

New business models arising from use of STEP standards could therefore include:

- Dynamic information management – data management throughout the lifecycle

- Blockchain monitoring – to conserve data integrity

- More effective recovery and recycling – to conserve resources

- Lifetime identification of products – for repair and modification

- More complete information for new processes – such as additive manufacturing.

Challenges and opportunities ahead

The workshop between IOM3 and BSI identified some of the challenges facing the wider adoption of STEP standards as the basis of a digital strategy for the materials sector:

- How to show the benefit to more companies of digital interoperability, traceability, sustainability, and quality management for the whole product lifecycle. Innovation is faster in the knowledge economy.

- How to involve more companies and people in the development and exploitation of this technology and to include software developers and vendors.

- How to move AP235 from testing processes to applications in the wider scope of manufacturing

- How to impress budget managers and senior executives of the financial benefits of this technology.

- How to generate a ‘pull’ for the technology so that it could be implemented in more software systems

The main aims and objectives of the workshop were achieved in what was the first discussion of this subject in recent times within IOM3. Several challenges were identified and some actions to address these were agreed. The digital representation of the properties of engineered products based on STEP standards will now allow for the direct association of valid digital property data with an actual product and provide a new opportunity for this association to be maintained and augmented for the whole product lifecycle. The possibility to combine the standardised representation of materials data with other STEP standards for engineering information would provide opportunities for new business models and new methods of working.

The recommendation to IOM3 was that this workshop should be the start of a larger effort to develop and promote a digital strategy for the materials sector.