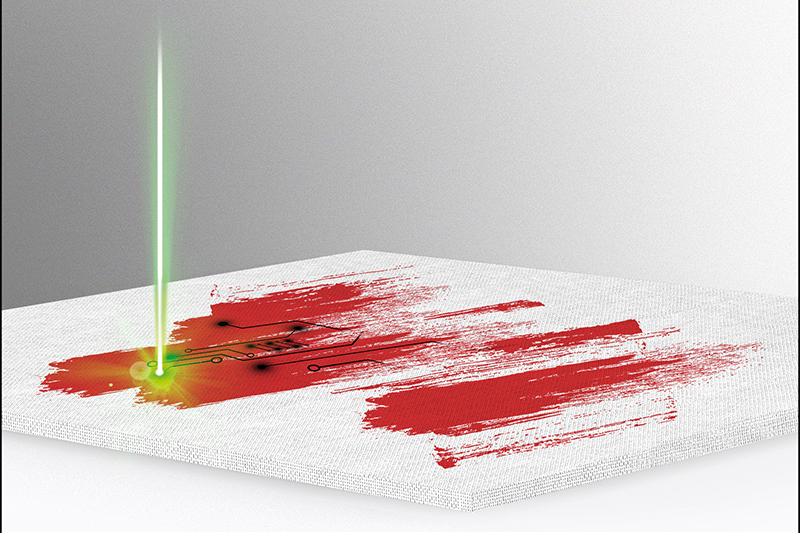

The thin red electric line

An electrical circuit has reportedly been created using only a red marker pen and a laser beam.

As part of the European project 5DNanoprinting, a research group has used a laser beam to transform the ink into a porous and conductive carbon called ‘laser-induced graphene’ (LIG).

This upends previous assumptions that LIG could only be obtained from certain plastic materials and polymers, claim the researchers from Sant’Anna School of Advanced Studies, University of Florence, and the Center for Colloid and Surface Science (CSGI) in Italy, as well as Graz University of Technology, Austria.

The red marker pen contains a specific dye called Eosin, which the group says has a chemical structure similar to graphene and is highly temperature stable.

Alexander Dallinger, post-doc at the University of Graz, observed the strange behaviour of the ink when irradiated by a laser by chance.

'I was trying laser writing on other materials, without success,' Dallinger shares, 'none of them were transformed into conductive graphene. I had written the name on one with a red marker to recognise it. By mistake, the laser beam passed over the writing – right at that point I saw a black trace appear. Intrigued, I immediately analysed it. The trace was conductive, and it was graphene.'

The experience in colours and pigment chemistry of scientists at the University of Florence and CSGI was essential when analysing the inks’ composition, and in identifying which dye was responsible for the graphene’s formation.

To transform the colour into a circuit, the team defines the design on a computer and traces the colour on a surface of their choice – such as a sheet of paper, coffee cup, or a pair of glasses.

The laser machine traces the design onto the coloured surface, and when exposed to the laser, the Eosin dye chemically transforms into graphene.

Until now, this ‘paint and scribe’ approach was thought to only work on polymeric precursors, explains the group.

The team believes this approach of ‘writing’ circuits directly onto any surface could boost applications in sectors such as printable electronics, biomedical sensors, robotics, automation and environmental sensors.

They have started studying other dyes from natural materials, with the aim of creating ‘green electronics’.