Maximising the use of important elements with plasma

Using argon plasma, metal atoms can be dispersed and guided to desired positions without waste.

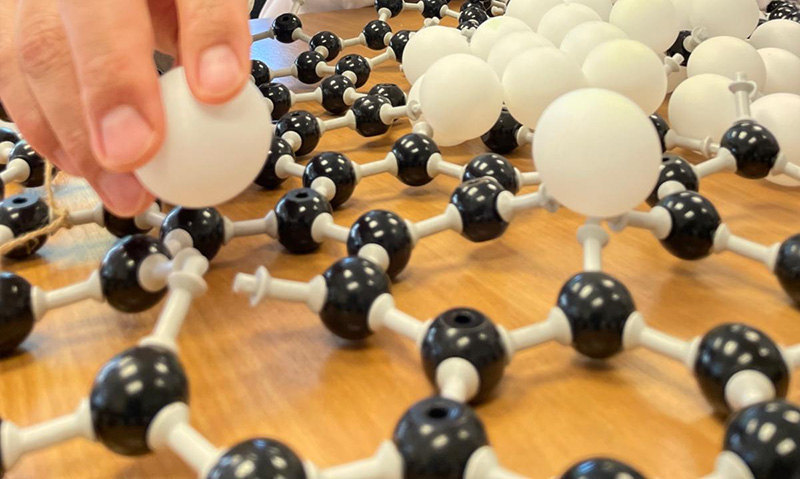

Demonstrating how atoms are guided and bonded to precise locations on a carbon surface

© University of NottinghamIn a study published in Advanced Science, researchers from the University of Nottingham, the University of Birmingham, Diamond Light Source and the EPSRC SuperSTEM demonstrate how using fast argon ions to engineer defects on carbon surfaces allows metal atoms to bind and self-assemble into ultra-thin, single-layer metal clusters, forming unusual 2D metal islands of sub-nanometre size.

Uses for the discovery could include siting metals for catalysis, or critical minerals for the energy transition.

‘Every atom counts,’ says Dr Emerson Kohlrausch, lead experimentalist on the study from the University of Nottingham’s School of Chemistry.

‘Precious and rare metals are vital for clean energy and industrial catalysis, but their supply is limited. We’ve developed a scalable strategy to ensure not a single atom goes to waste.’

Unlike conventional approaches that require element-specific conditions or chemical dopants, the team’s method exploits atomic vacancies, tiny holes created by argon ion bombardment on a carbon surface, as universal binding sites.

These defect sites act as atomic traps that strongly anchor metal atoms, preventing them from forming larger and less efficient 3D nanoparticles.

The method proved effective across 21 different elements, including difficult-to-control metals such as silver and gold. The innovation lies not just in trapping atoms, but in doing so under pristine, solvent- and air-free conditions that prevent site passivation.