Sustainable solution to ‘red mud’ mining waste enters final testing stage

A technology that could rehabilitate mine waste back to useful soil is entering full-scale trials at two Queensland refineries.

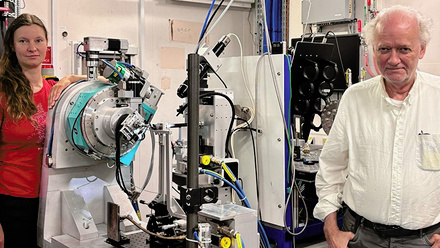

Researchers at The University of Queensland’s Sustainable Minerals Institute (SMI), Australia, developed the bio-engineering technology in partnership with Rio Tinto and Queensland Alumina Limited (QAL).

SMI Professor Longbin Huang says the process would transform the bauxite residue known as ‘red mud’ into a soil-like material capable of hosting plant life.

‘This project demonstrates how transformative industry-academia partnerships can be – Rio Tinto and QAL have supported the research for the past eight years, from proof of concept to full field trials,’ says Huang.

There are more than four billion tonnes of red mud stored in dams around the world, with Australia the second largest producer of the mineral waste by-product of alumina refining.

’The salinity and alkalinity associated with the minerals in red mud means rehabilitation can be challenging,’ Huang adds.

‘The process we have developed…involves eco-engineering the mineral and organic constituents of the red mud into material that is more hospitable to plant life.

‘It is a more sustainable and cost-effective way of managing red mud compared to traditional methods, which require companies to excavate and transport metres of topsoil from other locations to cover thousands of hectares of waste.’