Soy side-stream breeds bioplastics

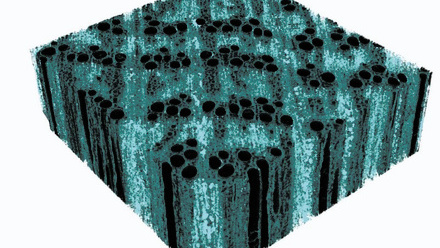

Four Finnish companies have collaborated to produce what they claim is the first compostable bioplastic made from food and feed production side-streams for application in thermal insulation in buildings or truck bodies.

Thermal insulation manufacturer, Finnfoam, biosourced materials company, Brightplus, VTT Technical Research Centre, and food processing company, Nordic Soya, are exploring the use of soy molasses (soy processing side-stream) as a raw material for fermentation and polymerisation to polylactic acid (PLA).

‘The process developed as an outcome of this cooperation project is the first in the world to produce an ecological lactic acid polymer from the side-streams of soy production. This way we can offer a sustainable alternative to sugar- and corn-based PLA,’ says Henri Nieminen, CEO of Finnfoam. Unsuitable for food production, soy molasses are typically disposed of through incineration.

The production process combines synthetic biology, chemistry and material technology. It consists of four stages – the team pre-treats the soy molasse using only pH control. Secondly, it ferments with genetically modified yeast to produce lactic acid, followed by a downstream process/purification. Lastly, Brightplus executes lactic acid polymerisation to PLA. Tiina Nakari-Setälä, Vice President of Strategy and Business Intelligence at VTT, notes that fermentation and purification have been achieved in 1,000L working volume, however, ‘the scalability of the full process to tens and hundreds of thousand litre-scale needs to be proven.’

The companies are launching a pilot plant project in Uusikaupunki, Finland, in connection with Nordic Soya Oy, the largest soy protein concentrate processing plant in the EU. The full-scale plant is expected to be operating by the end of 2023.