Fortifying wood with nano-iron

Infusing red oak with ferrihydrite reportedly strengthens the material at the cellular level, without adding weight or altering flexibility.

Scientists at Florida Atlantic University, USA, suggest it offers an alternative to steel and concrete in some applications. The treated wood reportedly retains its natural behaviour but gains internal durability.

The researchers claim few studies have investigated how treated wood performs at different scales, and none have successfully strengthened entire pieces of wood by incorporating inorganic minerals directly into the cell walls.

Dr Vivian Merk, Assistant Professor at the University, says, 'In contrast to many other chemical modifications, this approach targets the wood cell-wall instead of the larger macropores (lumina). Notably, there are fairly few chemical modification methods that have been successfully implemented in bulk wood.'

The team has focused on ring-porous hardwood, which comes from oak, maple and walnut. They have specifically studied red oak, a common hardwood in North America.

They formed ferrihydrite in situ within the cell wall to reinforce it. They mixed ferric nitrate with potassium hydroxide to produce ferrihydrite.

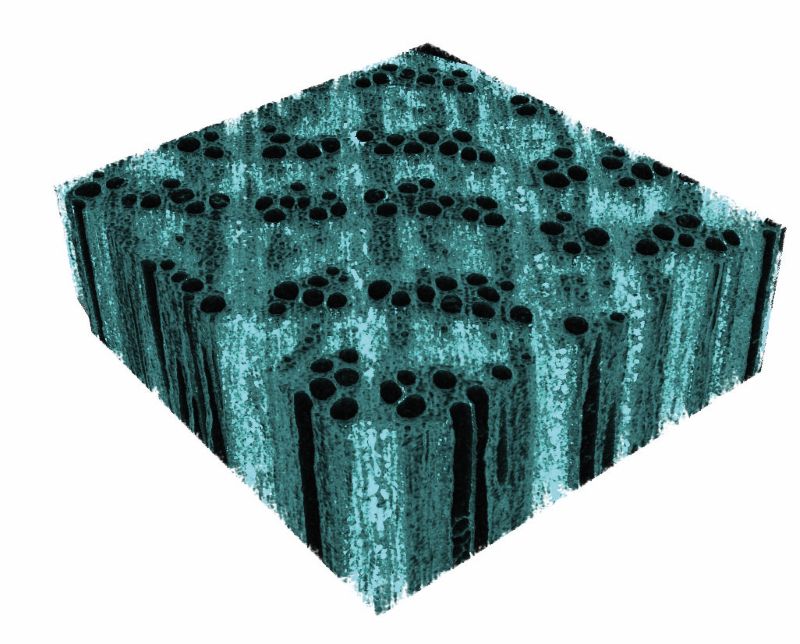

The nanocrystalline iron oxyhydroxide was introduced into the wood’s xylem through a chemical reaction that can strengthen the tiny pores within the cell walls while adding a small amount of extra weight.

So far, they have tested the protocol for balsa and oak wood. Merk says, 'The two wood species differ dramatically in density; therefore, we are confident that the modification method is suitable for many different wood species.'

The researchers used atomic force microscopy and nanoindentation to measure stiffness and elasticity. They achieved a precise view of how the wood’s cell walls were altered after being treated with minerals.

Additionally, the team conducted nanoindentation tests within a scanning electron microscope and performed mechanical tests – such as bending both untreated and treated wood samples – to evaluate its overall strength and how it broke under stress.

Merk says, 'At the cell-wall level, we achieved a reinforcement of a factor of three compared with pristine wood. However, we did not see such a significant improvement in bulk bending tests. This could be due to residual hygroscopic salts (e.g., KOH, KNO3) retained in the cell wall after washing that could increase the relative equilibrium moisture content, or an impairment of the compound middle lamella that holds two adjacent cells together.'

The weight gain reportedly depends on the sample size, geometry and wood species. For instance, a weight gain of 2.83% was determined for samples measuring 100mm × 5.5mm × 19mm, which is on the order of a veneer.

Merk adds, 'It is possible that some wood components (e.g., extractives in oak wood) leach out during the chemical treatment.'

Researchers report that they took inspiration from hybrid composites in nature that are based on a polymer scaffold, such as chitin, and ultra-hard iron-oxide minerals.

Merk explains, 'An important design criterion was that the chosen mineral is insoluble and extraordinarily hard.'

Ferrihydrite naturally occurs in many soils and sediments. The chemical reaction of ferric nitrate and potassium hydroxide occurs in water at ambient temperature without producing harmful by-products. It is also part of the ferritin core of many living organisms. Merk asserts, 'We tested in a previous study that little iron leaches out of the composite.'

They are interested in upscaling the process and finding an industrial application. They believe the modification is scalable due to the low cost of the chemicals, the straightforward modification procedure and water as a solvent.