Scalable process upcycles polyethylene into polypropylene

A proof-of-concept study for upcycling waste polyethylene (PE) into virgin polypropylene (PP) could lead to high-value recycling of PE and circular plastic use, say the US researchers.

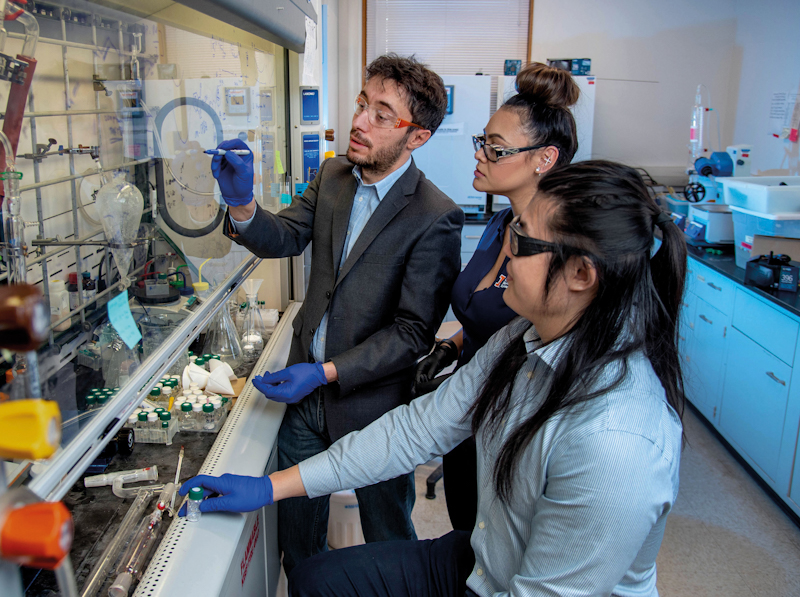

The method was developed by a team from the University of Illinois Urbana-Champaign, the University of California, Santa Barbara, and the materials science company Dow.

This builds on a 2020 study by the Illinois team, which predicted how olefin metathesis and excess ethylene and isomerisation could convert PE into propylene.

'The earlier theoretical study established that the reversible nature of the tandem reactions – ethenolysis and isomerisation – require either very high ethylene pressure in a closed vessel, or ambient ethylene pressure in a flow reactor to produce PP selectively from PE,' explains Professor Susannah Scott at UC Santa Barbara.

Scott explains that this research performs the reaction at ambient pressure in a flow reactor with a heterogeneous catalyst that makes it more viable for large-scale reactions.

For proof-of-concept, they found a compatible 'suite of catalysts' to transform PE into PP with more than 95% selectivity, and designed a semi-continuous reactor.

'Previously, we used a similar reactor for a completely different reaction for which we needed a solvent that would not evaporate,' explains Professor Damien Guironnet at the University of Illinois, USA.

'We decided to use a polymer for this purpose, which gave us the idea of using the same reactor set-up to depolymerise PE, where ethylene is fed continuously to the reactor and the low molecular weight product (a gas) that forms leaves the vessel. We had to optimise the rate of addition, the temperature and the catalyst loading.'

Scott explains that high molecular weight PE is a very inert material which melts to give a highly viscous liquid, and so, taking this into consideration, the team started with more tractable materials to evaluate the catalysts and the rector design.

In this study, a catalyst removes hydrogen from the PE, creating a reactive location on the chain. Next, the chain is split in two at this location using a second catalyst, which caps the ends using ethylene. In the final step, a third catalyst moves the reactive site along the PE chain so the process can be repeated. In the end, only a large number of propylene molecules are left.

The study’s semi-continuous approach offers the additional advantage of creating a product stream with a composition similar to that obtained in steam cracking – the current process for producing ethylene and propylene, add the researchers.

'This means the infrastructure to separate propylene from ethylene is already well-developed, which is a major benefit for the future implementation of our technology,' says Guironnet.

Before their method can be scaled up, further work is needed. 'In addition to the need to improve catalyst activity and stability, a challenge faced by all chemical recycling strategies is the purity of the plastic waste stream,' says Scott.

'The coupled reactions we demonstrated will work exclusively on PE – other polymers will not react. However, additives and other components can poison the catalysts and this means that plastic waste sorting and cleaning will be extremely important.'