Recycling unstuck with dissolvable adhesives

Adhesive residue left on recyclable materials, such as glass and cardboard, can now be dissolved using degradable polymers, say University of Surrey, UK, scientists.

Sticky residue causes problems in the recycling industry, ranging from low-quality products, blocked water systems and even damaged recycling machinery.

The new adhesive, which is similar to that used in commercial packaging tape, has a chemical additive known as thionolactone that makes up 0.25%. This additive allows the adhesive to be dissolved in the recycling process.

The researchers report that labels can also be detached up to 10 times faster when compared to a non-degradable adhesive.

This achievement was possible because of a recent discovery at the University of a method to introduce ‘breakable’ connections into the relevant type of polymer chains using thionolactone.

Dr Peter Roth, Senior Lecturer at the University, says, 'One of the most important types of polymer is made from vinyl monomers and contains only carbon-carbon bonds in the chains. These bonds are stable and give plastics durability. But these bonds are not degradable.

'Commercial labels and tape contain polymer chains that are usually irreversibly connected together in a 3D network. These networks cannot be dissolved in solvent during recycling. Our work introduced a small amount of degradable connections in the polymer network – just enough to allow the network to be decomposed into single polymer chains.'

He continues, 'When the thionolactone reacts with the growing chains in the polymerisation reaction, it uniquely installs sulphur atoms into the chains in a chemical pattern called thioester. These thioester connections in the chains can be broken on demand through chemical treatment. This breaks the intact chains into shorter chains.

'The process used to install degradable connections into chains is called radical ring-opening polymerisation and has been around for several decades. But our thionolactones are the first to install thioesters into polymer chains. A reason that our new method has already attracted attention from other research groups and industry…is that these thioesters can be broken very quickly and selectively, whereas conventional systems require harsh conditions and/or long time.'

Importantly, they 'showed that the degradable connections remain intact during storage (up to four months)…This means the presence of the degradable thioester connections does not influence the behaviour of the adhesive. Only when dissolution is intended and suitable chemical triggers are used, do the thioesters break and the adhesive becomes soluble'.

The adhesives require chemical treatment with substances called thiols that are present in some food. 'In fact, we showed that a non-toxic dietary supplement (called N-acetylcysteine) can be used to dissolve adhesive residue,' says Roth. They now wish to develop adhesives that can be dissolved in even milder conditions.

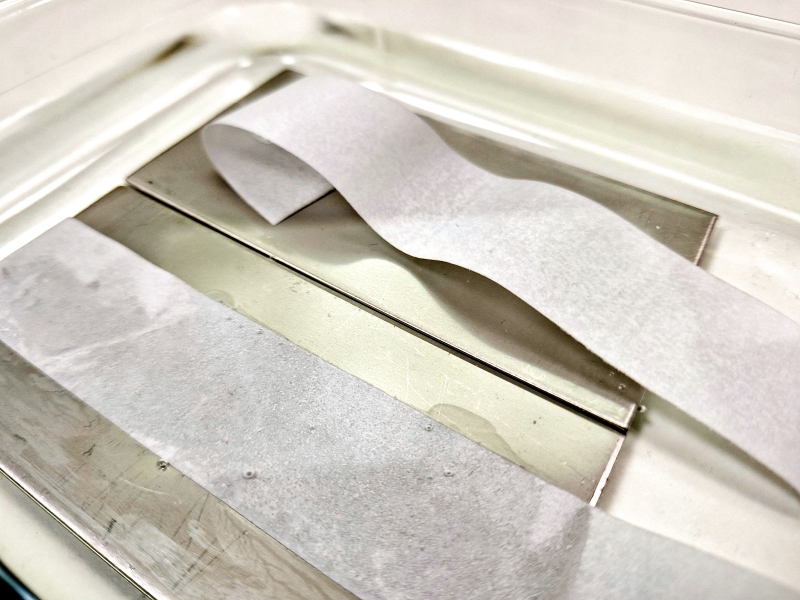

In their study, the degradable adhesives adhere to paper, plastic, glass and metal.

They are now working with industry to push the research further. Roth adds, 'Firstly, while the current thionolactone (called ‘DOT’) works quite well, there are some types of vinyl monomers it is not compatible with. We are working on second-generation thionolactones that have improved properties and can be produced on a large scale.

'Secondly, we are exploring applications of our new thioester-functional polymers. We hope to expand the work on degradable adhesives with industry and plan to explore biomedical applications of the degradable polymers, for example, for drug delivery.'