Real-time analysis of ceramic sintering

Morgan Advanced Materials conducts real-time ceramic sintering research at Diamond Light Source.

The company reports the completion of high-temperature, X-ray diffraction (XRD) research, to further understand the firing behaviour of alumina ceramics at the critical point of sintering.

The purpose was to see what phases are formed through the sintering temperature range of one of their alumina grades with the aim of understanding the sintering behaviour in relation to temperature.

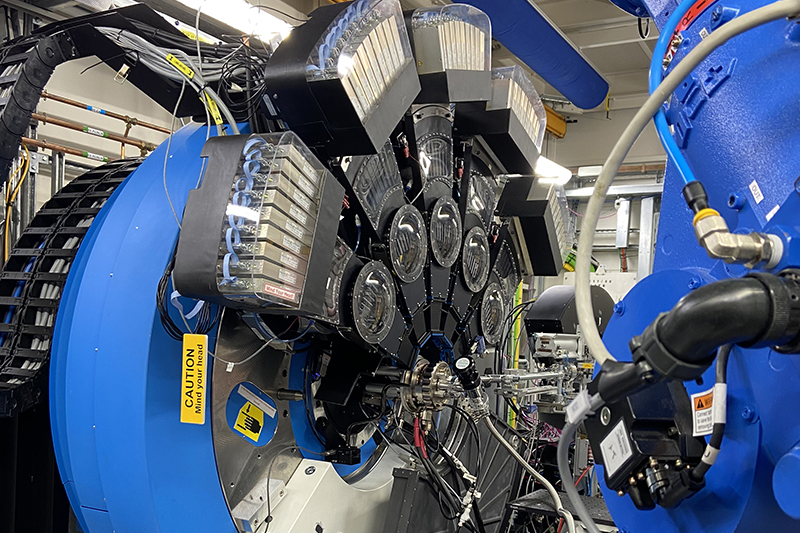

The Morgan Technical Ceramics team at Stourport, UK, used the XRD facilities at Diamond Light Source facility to complete the research.

The research was conducted over two 'beam time' sessions, using diffractometer equipment that gathers data at an accelerated rate, as 30 minutes beam time is the equivalent of one month's acquisition time on other XRD machines.

Dr Yi Cui, Senior Materials Engineer at Morgan Technical Ceramics, says, 'The results have uncovered a new phase, which appears during the sintering process, and this has underpinned our understanding of the firing temperature limit which has to be applied to this material.'

This is the first time the company has conducted real-time analysis through the sintering range for ceramic materials.