Ready for a blast - a satellite to track volcanic ash cloud

Over 200 students, over seven years, have been involved in constructing a satellite payload at the University of Bristol, UK, to monitor active volcanoes.

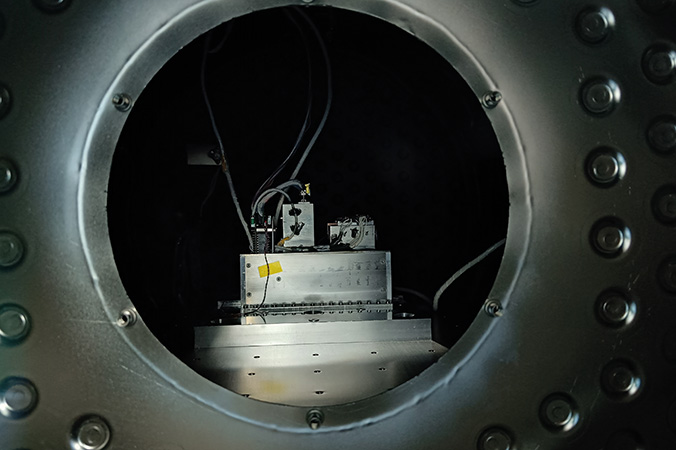

Pathfinder in the thermal vacuum chamber

© UoBSatSarah Morgan caught up with three of the students after the device was tested at the European Space Agency earlier this year.

Students at the University of Bristol, UK, have moved into the fast lane. Their mission? Build a CubeSat payload as a technology demonstrator for detecting and tracking volcanic ash clouds using novel sensing technology. The payload is the part of the satellite that holds the volcanic imaging equipment.

As well as improving our understanding of volcanoes, the information could save the aviation industry millions by helping to keep planes in the air after an eruption. After all, a grounded aeroplane is costly business.

The 3D structure of ash clouds offers vital knowledge as airlines and engine manufacturers move towards airspace management based on a ‘dose-based ash cloud approach’. This means defining an engine’s ash susceptibility based on the ash dose.

But to do that modelling, a satellite first needs to withstand the hostile environment of space, including extreme vibrations during launch, an airless vacuum and temperatures ranging from the very hot on its sun-facing side to the very cold on its space-facing side.

In collaboration with the University’s Engineering, Physics and Earth Sciences Departments, the project is student-led, building on designs made as part of many undergraduate and postgraduate projects from across several faculties, as well as extracurricula work.

The satellite payload has had the support from the Education Office of the European Space Agency (ESA). The result, PROVE – Pointable Radiometer for Observation of Volcanic Emissions – Pathfinder is a potential payload for the University of Bristol’s planned Cubesat mission.

Joining forces

The level of student involvement makes this project special, with 200 students taking part over seven years. They range from first years to PhD researchers, and are supported by a small team of the University’s professors. This was an opportunity for the students to work in an interdisciplinary team, across areas such as aerospace, civil and electrical engineering, as well as physics.

The team size at any one time was about 25 people, all mainly working in the same room and each group had a team lead for their respective areas.

Fourth-year Aerospace Engineering student Tom Snelling acted as Project Manager for the whole team and the Quality Assurance Manager for the ‘vibration campaign’. Third-year Aerospace PhD Student David Reid was the Structural and Thermal lead and acted as the specialist in these domains in the ‘thermal campaign’. And Louis Timperley was Software and Systems Lead and acted as the Quality Assurance Manager for the ‘thermal campaign’. He is a third-year PhD student.

Timperley shares, 'On one hand, my group would be writing the flight software that will be running on the payload, whereas George [fellow student] and his team would be developing the electronics.'

For Snelling, as Project Manager, this meant ensuring that every single sub-team was on track and ready to have the full engineering qualification model built. He recalls it felt like each review stage for testing came upon them fast. 'There was a lot of communication particularly between me and these guys, on a weekly or daily basis.

'What is different is I, as an undergraduate, would never normally work side-by-side with both graduates and staff.'

Reid adds, 'The benefit of the project, I guess, is you have the experiences that make you stand out from the rest of the candidates when applying for internships and jobs…But it also leads to a downside that people are constantly leaving the project going off to do really cool things.'

Taking flight

Earlier this year, eight of the students went to the ESA’s CubeSat Support Facility in Transinne, Belgium, which is one of the few places in Europe that has the multimillion pound facilities needed to simulate space.

The tests carried out there were the culmination of thousands of hours of research, testing and trial builds at the University of Bristol.

At 20cm x 10cm x 10cm, the payload is around the size of a standard house brick. But its two cameras – one high resolution and one infrared – are capable of tracking and modelling ash clouds in ways that have not been tried before.

At ESA, the students’ payload was shaken with violent vibrations before being plunged into a thermal vacuum chamber and subjected to maximum and minimum rated temperatures at extremely low pressure.

The students had to be selected for the ESA programme before it moved from the theoretical Bristol paper to a practical ESA project for testing. The project that Snelling, Reid and Timperley were involved with was part of ESA’s Fly Your Satellite! Test Opportunities programme.

To be selected, they had to write a roughly 60-page technical application, which Snelling says, 'took up most of my August last year, and I think we heard about the result around the end of October'.

How did it feel to be selected? After a pause, Timperley says, 'very nice'. They laugh. He expands, “We were perhaps maybe a little surprised and naïve. I guess, slight terror.”

Reid adds, 'We had no idea what we were getting into…I daresay most of the things we wrote in the initial 60-page report went out the window fairly quickly. I think the 400 pages of technical specification we ended up producing as part of the opportunity was completely different.'

He explains, 'When we applied for the programme, our design was a [computer assisted design] CAD model. So, over the course of six months, we completely redesigned the model and then went to aluminium bits assembled in front of us to allow us to test it.” He adds modestly, “So I guess that’s my personal contribution.'

Timperley continues, 'Throughout that, we needed to be ready to debug and test our payload…Well, luckily for me, most of the software was already written before we were accepted for testing. So, I ended up writing most of the documentation for it, which is basically specifying what the tests were going to be and then the series of steps that we would follow to carry out the testing.'

Why is ESA a draw? 'They’re kind of the gold standard for what we call systems engineering and just best practice, especially in Europe. And their educational programme doesn’t really have a competitor anywhere,' says Snelling.

'If we had the money to, we could have paid to use a test facility somewhere in the UK. But none of those test facilities would have been able to work with us for six months and meet with us on regular basis to come and do the work and come up with how to do it.

'At ESA, they were very happy to teach us what we didn’t know. Certainly, standards were high.'

He stresses it was a very hands-on project, “Everyone’s got a dedicated role – we can’t waste a minute because time is so valuable. Everything must be done to an exact procedure. Everything must be ticked off, checked, quality inspected, to do the test. But it’s not us asking ESA to do the test and sit back, it’s us as the customer instructing them what to do as the test operator.'

So, inevitably this brought specific challenges, such as the fundamental one of juggling everyone’s degrees at the same time as doing the equivalent of a full-time job for six months. Snelling reflects, “I think that was probably the biggest shock.'

They also highlight technical challenges, 'such as thermal paths for cameras that are designed to work on Earth, where the air moves most of the heat for you. In a vacuum, you don’t get that, so the cameras don’t behave the same way'. There was also the matter of manufacturing considerations and concerns around outgassing.

Snelling says, 'One of the worst things for outgassing includes thermal pastes…It’s terrible because if you have material that outgases, it can coat the lens of your camera in some foggy, cloudy material.'

Meaning you can spend “quite a considerable amount of time and effort and money putting something in space to take a picture of fog and nothing else'.

He explains, 'We had some very funky thermal basic glues, threadlockers for bolts to ensure that things stayed in. We had to meticulously catalogue every single material down to the constituent materials within cameras as best we could and then give that list of approved materials basically to the test facility, because the ESA’s vacuum chamber is very expensive and extremely clean. So, you have to ensure that you don't compromise that.'

'We did have to get support from industry – Polymer Systems Technology Limited – for the thermal paste because the specific thermal paste is really expensive because of such a small use case for them. We were a bit more fortunate with glues because there’s a bit more of a defined market for those because it just happened to be easier to keep them within tolerance, but specific tests to validate unusual material properties are expensive to run.'

He observes, 'It’s a very interesting area of material science that I never considered', until faced with it on this project. 'It also ramped costs up and makes it even harder from a budget perspective for the University and me as the Project Manager.'

Safety first

They were all given free rein to do testing. However, this was within strict parameters such as those they were already familiar with from university procedures. Which, while it slowed down the testing process, ensured a safe project, where they reported no issues.

Reid says, “Our methods within the University are very rigorous for a reason.”

Some work was during the pandemic, which Timperley says was 'difficult'. He continues, 'It was part of the reason I guess why our structures only existed in CAD is that it was very hard for us to start working on physical hardware. This slowed everything down…The hardware was [also] too expensive for us to ship around the world, so that people could work on it in a remote setting.'

On a wider level, Snelling said he was confronted with a perplexing issue in working internationally and crossing customs lines with an export-restricted camera. He says, 'When we flew into Luxembourg [to the ESA], communicating with the Luxembourg border force that speak French, and only French, that you have this thing in a box and there’s a lot of wires hanging out is very questionable, and convincing them that it’s for a Space Agency project for university students and not something else was difficult!'

Golden opportunity

Having access to the ESA’s state-of-the-art facility was an inspiring opportunity for the team and one they do not take for granted. They are fully aware that standard access costs serious money.

Timperley says, 'ESA is by far the largest customer for any space projects performed in Europe. So for employability for the students, it is great to get exposure to ESA’s procedures and ways of going about things. If you end up with a job in the space industry, you will probably end up working with them again.'

They see their futures in this type of work, with Reid saying, 'My PhD is on Martian dust storms. So eventually, any submissions we make are what I want to end up working on.' He hopes to be working with ESA specifically in the future.

The immediate project remains 'really exciting', says Snelling. Their knowledge is ever evolving. Reid adds, '…in terms of actually going and doing the testing, we had to create various numerical models of the payload. So, one to simulate structural testing in vibration and one to simulate the thermal behaviour of it in a vacuum, and it's safe to say they were quite different to what we saw in the testing. But that lets us then update the models to make them better.'

Reid concludes, 'We just need to make sure we maintain momentum…If and when we get it in orbit, and we can start getting data back, that’s when our Earth Sciences Department will start to get a lot more involved.'

The geologists, while having a smaller role at this stage of the project, steered the initial parameters.

Satellite testing is ongoing. They hope to launch it in 2024.

Professor’s perspective

Lucy Berthoud, Professor of Space Systems Engineering at the University of Bristol, UK, is supporting the students. She says, 'Few UK universities build satellites. This payload is really ambitious. If it’s successful, it will improve our understanding of ash clouds.

'This is a student-led project, so it wouldn’t exist without the students. They are pushing research forward that normally wouldn’t happen without funding or investment.

'To do this, the students have been learning hands-on skills to build and test a satellite which will equip them well for positions in the space industry when they finish.

'They are a delight to work with. We give them full responsibility and just try to support them with things like buying some hardware and paperwork.

'There is a diverse range of experience in the team and this is one of the delights – we have third-year PhD students working with first-years.'

She finds, “They are busy sometimes on coursework and during exam season and so the work can ebb and flow a little. Also, we keep having to recruit and train new students as some of them graduate each year. There are never any problems recruiting students to the project as space is inspiring and exciting for so many different disciplines.

'Every day I learn something from the students, it is one of the joys of this job.'

Finally, the most memorable aspect of the work for her were, 'the pizza evenings' she jokes.