Plastic-to-oil system reaches UK

A full-scale plastic-waste-to-oil recycling system is coming to the UK with oversight from QM Recycled Energy (QMRE).

Further processing of the oil transforms it back into new and renewable plastic.

QMRE is the first company to introduce the Eagle Technology Vixla system.

It converts 1,000kg plastic waste into 1,000L of pyrolytic oil and will be installed and trialled by QMRE during the first quarter of 2024.

For the past three years, QMRE has been operating a smaller version of the plastic-waste-to-oil system on a test and development basis at its site in Kent.

The lessons learnt were valuable input for Eagle when they started developing Víxla (the Norse word for transformation).

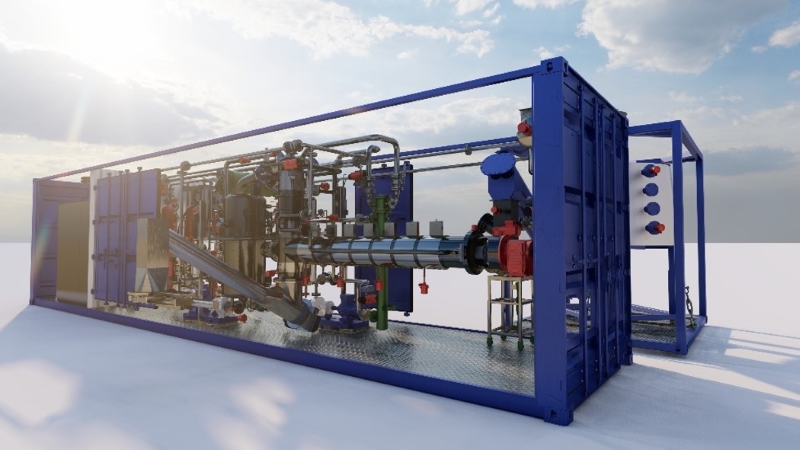

The system is based on Eagle’s Induction Thermal Desorption Unit (ITDU), a pyrolysis plant capable of processing 60t/d of drill cuttings. It uses QMRE’s technical developments that turn the operation into a thermolysis system.

It allows for decentralised processing of plastic waste, reportedly eliminating the need for transportation to large, centralised factories. This approach is said to offer economic advantages and reduces the environmental impact of plastic waste.

The containerised system is scalable to meet varying local needs.

A planned roll-out of production systems, with 5t/d capacity, is scheduled throughout the remainder of 2024 and beyond.

QMRE is introducing a network of Víxla systems throughout the UK and Republic of Ireland.

'We are delighted with QMRE as the partner for our first delivery. With years of operational experience and an experienced and skilled team, we are confident that it will be a perfect place for joint learning to further develop and optimise the system together', states CTO of Eagle Technology, Ørjan Samuelsen.