Recovering high-purity silicon from waste solar panels

A method for extracting high-purity silicon from solar panel waste for use in lithium-ion batteries has been developed by NTU in Singapore.

Existing methods are reportedly energy-intensive and involve multiple highly toxic chemicals, making them expensive and limiting their widespread adoption.

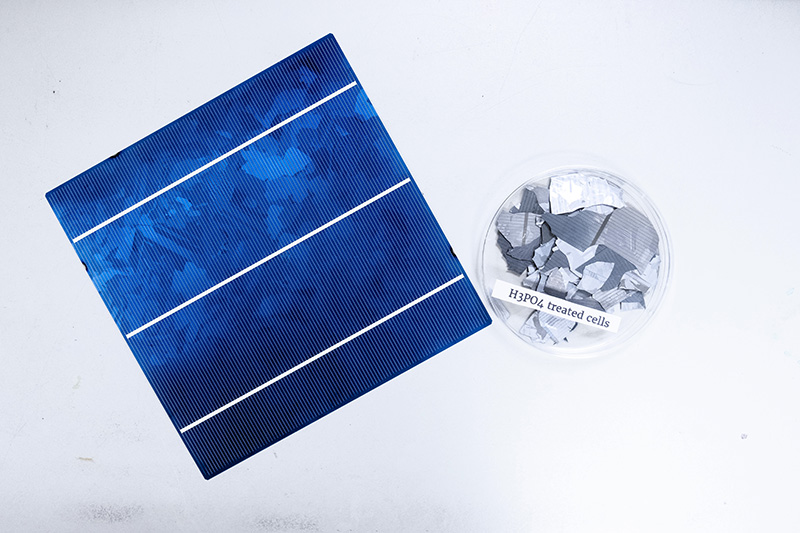

The NTU extraction method using just phosphoric acid is said to overcome these challenges. Their approach reportedly demonstrates a higher recovery rate and purity than current technologies.

Dr Sim Ying of NTU says, 'Generally, multi-step procedures are used to recover silicon from an end-of-life solar cell. The steps include treatment with acid like nitric acid and/or base like potassium hydroxide.

'Such approaches will require a washing step in between to minimise cross-contamination. Even so, the anti-reflective coating (ARC) is not removed from the surface. High-temperature annealing with etching paste or further complex treatment needs to be performed for the ARC removal.'

Here, 'instead of going through multiple steps with specialised chemicals, our team devises a simplified single-reagent approach to directly recover silicon'.

Ying explains, The cell is placed into a heated phosphoric acid solution (approximately 75°C) to first dissolve the aluminium back contact and partial detachment of silver contacts. Once the aluminium back contact is completely removed from the cell, the cell is retrieved and dipped into a fresh solution of phosphoric acid for further removal of the ARC. The cell is lastly rinsed thoroughly with deionised water and dried in an oven overnight to recover >99% purity silicon.'

The idea of using phosphoric acid came about after examining the potential of other inorganic acids. Ying shares, 'The team started off with exploring the potential of different common acids such as methanesulfonic-, phosphoric- and acetic-acid. These acids are either organic acids or milder acids that align with the team’s objective to develop environmentally friendlier strategies. After all the trials and testing, we observed that phosphoric acid not only dissolves aluminium, it also attacks the ARC and diminishes the blue surface of solar cells.

'The reaction of acid with ARC will also aid the detachment of silver from the surface, enabling recovery of silicon.'

Ying explains how the technique was trialled at different temperatures. Additionally, the acid concentration was also varied to find the optimal point for full removal of aluminium, silver and the ARC to recover silicon. The optimal condition requires the first step with 14 molarity (M) acid and then 8.5M acid.

The economics are still under study. Ying says, 'We foresee that it will be less costly due to the use of only one chemical, which also avoid additional washing needed between different reagent treatments.'

They are 'actively reaching out to connect with interested parties to validate this developed process with us at a larger scale…We are positive that the process will work with some fine tuning on the operational conditions'.