Patent of the month – Wood-free fibre compositions for paperboard packaging

Dr Tahsin Ali Kassam at UDL Intellectual Property discusses a recently granted patent relating to wood-free fibre compositions used in packaging.

Non-wood natural fibres, such as field crop fibres or agricultural residues, are also considered sustainable alternatives for either completely, or at least partially, replacing tree-based fibres as hybrid paperboard compositions.

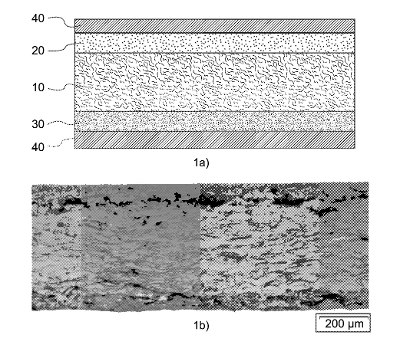

In July 2020, Kimberly-Clark Worldwide, Inc. was granted UK patent GB2557052B titled Wood-free fiber compositions and uses in paperboard packaging, which discloses a paperboard packaging material comprising a top layer (20) including non-wood fibres blended with wood fibres, wherein the non-wood fibres are 50-85wt.% of the top layer. A back layer (30) includes non-wood fibres blended with wood fibres, wherein the non-wood fibres are 50-85wt.% of the back layer. And a middle layer (10) is disposed between the top and back layers. Figure 1a shows a schematic illustration of the paperboard structure.

Optionally, the non-wood fibres are bamboo and/or the middle layer includes 5-100wt.% non-wood filler fibres made from corn stover, straw, other land-based natural fibres or combinations thereof. The straw may include wheat, rice, oat, barley, rye, flax, grass, and combinations thereof, while the other land-based natural fibres may include flax, bamboo, cotton, jute, hemp, sisal, bagasse, kenaf, hesperaloe, switchgrass, miscathus and combinations thereof. The packaging material may include a coating (40) of latex, kaolin clay, or calcium carbonate on the top and/or back layers.

The patent discloses a series of experiments demonstrating the usefulness of bamboo as an alternative natural fibre to conventional virgin long wood fibre in the top and back layers of a multi-layered paperboard structure.

In one example, a control sample of a 1:1:1 layered structure of pine, pre-consumer fibre, and pine was tested against a 1:1:1 layered structure of 50/50 pine/bamboo, wheat straw and 50/50 pine/bamboo made according to the invention. The inclusion of bamboo was found to provide superior mechanical properties as compared with the premium off-the-shelf packaging material with improvements in z-direction tensile strength and stiffness.

In another example, the top layer used 25wt.% Northern bleached Kraft Pulp (NBKP) and 75wt.% bamboo while the back layer used 15wt.% NBKP and 85wt.% bamboo. A significant improvement in the folding strength of the novel material was observed as compared with that of the control sample, and while the smoothness was only half that of the control sample, required specifications were still met. Figure 1b shows a SEM micrograph of another embodiment of the invention – the middle layer is made of bleached chemi-thermomechanical pulp (BCTMP) and the top and back layers include a mixture of wood-based and bamboo fibres.

Read the full patent.