Patent - Expansive cement for borehole applications

Dr Tahsin Ali Kassam at Murgitroyd summarises a recently granted patent relating to expansive cement

Cement used in downhole applications is susceptible to shrinkage during and after setting, causing small gaps known as ‘microannuli’ at interfaces, such as those between the cement and casing or borehole formation wall.

Cement systems that expand slightly after setting are a proven means of preventing and/or sealing the microannuli, thereby improving primary cementing results including effective zonal isolation.

In the restrained downhole environment, therefore, the cement can expand to eliminate voids, reducing internal porosity. However, additive compositions added to cements such as Portland cement rely on elevated temperatures to achieve sufficient expansion.

In September 2021, Halliburton Energy Services, Inc. was granted UK patent GB2543712 titled Expansive Cement.

The patent claims an expansive cement composition comprising a Portland cement; 0.5-8.0wt.% of a calcium aluminate cement; 0.001-0.50wt.% of a lithium compound; 1-15wt.% calcium sulphate; 0.1-3.0wt.% calcium hydroxide; and 0.01-1.00wt.% sodium bicarbonate.

The expansive cement composition may result in at least a 10% increase in volume when setting occurs at a temperature below 38°C.

The patent discloses that expansion is provided by the formation of ettringite, which results from the calcium aluminate and calcium sulphate. The lithium compound is postulated to enhance the expansion, such that it can be achieved at relatively lower temperatures as compared with conventional compositions.

The patent also claims an expansion additive composition for use in Portland cements comprising 5-50wt.% of a calcium aluminate cement; 0.01-5.00wt.% of a lithium compound; 1-20wt.% calcium hydroxide; and 0.1-5.0wt.% sodium bicarbonate. Optionally, the composition includes 50-8wt.% calcium sulphate.

The patent further claims a method for cementing a casing in a wellbore having a borehole wall, comprising the steps of placing a cement slurry composition between the casing and the borehole wall.

The composition comprising a Portland cement; 0.5-8.0wt.% of a calcium aluminate cement; 0.001-0.50wt.% of a lithium compound; 1-15wt.% calcium sulphate; 0.1-3.0wt.% calcium hydroxide; and 0.01-1.00wt.% sodium bicarbonate, wherein the borehole wall and casing are at a temperature below 38°C.

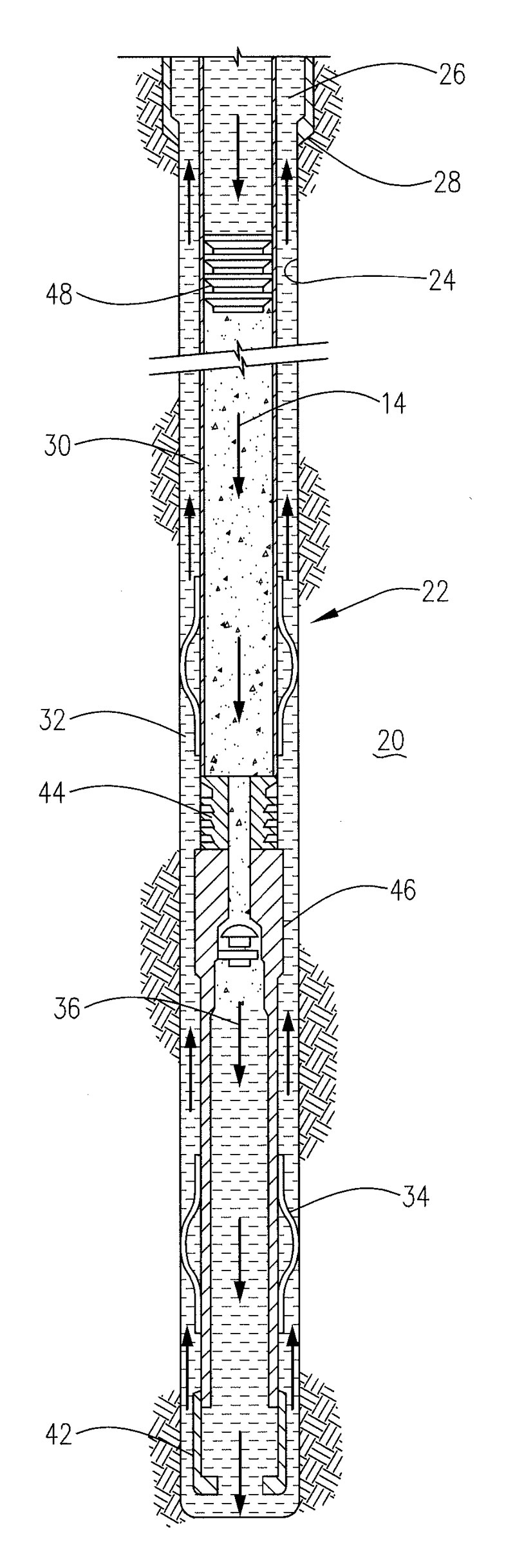

In the illustrated example, the cement composition (14) is placed into a subterranean formation (20) – a wellbore (22) having walls (24). A surface casing (26) inserted into the wellbore may be cemented to the walls by cement sheath (28). Additional conduits (30) may be disposed in the wellbore. An annulus (32) is formed between the casing and the walls and/or the surface casing. Centralisers (34) are attached to the casing (30) to centralise it in the wellbore prior to the cementing operation.

The cement composition may be pumped down the interior of the casing, through the casing shoe (42) at the bottom of the casing and up around it in the annulus – this may form a cement sheath that supports the casing’s position. Displaced fluids (36) may exit the annulus via a flow line (38) before being deposited in retention pits. A bottom plug (44) may be introduced into the wellbore ahead of the cement composition, and as it reaches the landing collar (46), a diaphragm ruptures to allow the cement composition through. A top plug (48) may also be introduced into the wellbore behind the cement composition.

The patent discloses results of tests performed on six cement additive samples that were cured in expansion moulds at 12.8°C over a seven-day period. All of the samples showed greater overall expansion relative to a Portland cement control sample. The sample containing 0.2wt.% lithium carbonate provided both the highest rate and overall expansion.

Read the full patent here: bit.ly/3p1rWqy