Nanomaterial harvests hydrogen from seawater

A nanoscale material that can split seawater into oxygen and hydrogen, balancing the competing reactions that are critical to electrolysis, could produce hydrogen fuel on an industrial scale and high-purity oxygen for hospitals, say researchers at the University of Central Florida (UCF), USA.

Until now, a host of technical barriers have prevented hydrogen from being harvested directly through seawater electrolysis. The biggest hurdle to overcome, say the scientists, is the electrochemical competition between the oxygen evolution reaction (OER) and chlorine evolution reaction (CER) at the electrode, as they have very similar thermodynamic qualities.

According to the study, published in the journal Advanced Materials, ‘the equilibrium potential of CER and the hypocholorite formation shows pH-dependence in alkaline solution, which competes with OER’, and undermines its Faradaic efficiency and electrolyser cell voltage.

In addition, ‘the poor stability of electrode materials further inhibits the continuous hydrogen production from seawater electrolysis’ – seawater being corrosive to the metal catalyst materials that are conventionally used for water splitting.

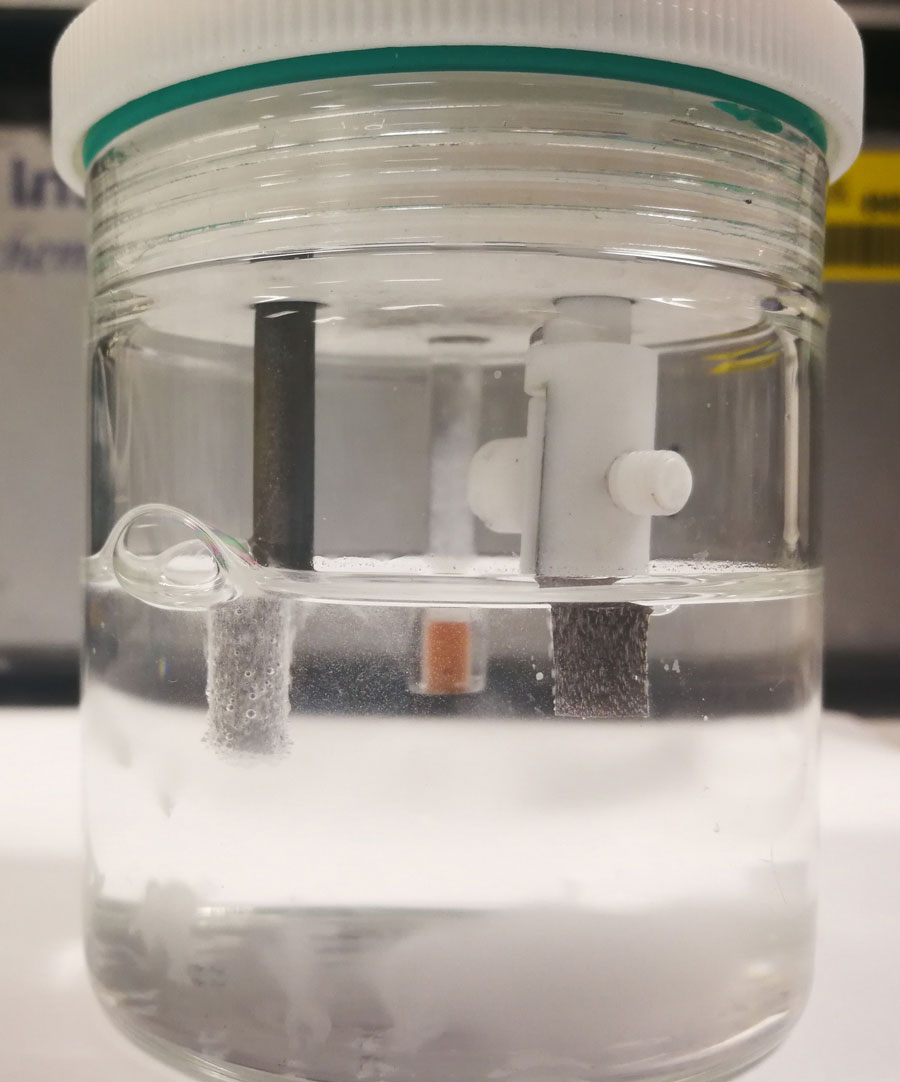

Using a laboratory reactor, the scientists have developed a thin-film material with nanostructures on the surface made of nickel selenide with added iron and phosphor measuring 600nm. The dual-doped nickel selenide nanoporous films – Fe, P-NiSe₂ NFs – are created using chemical vapour deposition apparatus to apply thermal treatment and work as bifunctional catalysts.

The Fe-doping increases the OER activity and selectivity, while the P-doping enhances electronic conductivity and improves the catalyst’s stability.

To test the nanomaterial’s electrocatalytic stability, the scientists have performed chronoamperometry and multi-cycle liner sweep voltammetry (LSV) to demonstrate that the hydrogen evolution reaction (HER) and OER activities are stable for at least 24 hours.

After 5,000 cycles, they find that the LSV polarisation curves for HER and OER show a negligible difference compared to the initial curves.

On testing electrolyser performance, they have found that an industrially required current density of 0.8Acm−2 is achievable at 1.8V for over 200 hours in a practical electrolyser using natural seawater feedstock.

‘The seawater electrolysis performance achieved by the dual-doped film far surpasses those of the most recently reported, state-of-the-art, electrolysis catalysts and meets the demanding requirements needed for practical application,’ claims Yang Yang, Associate Professor at UCF’s NanoScience Technology Center and the study’s co-author.

The scientists plan to build on their work by investigating further improvements in the material’s electrical efficiency, and developing high-performance hydrogen fuel cells and solar cells that incorporate the technology. While the generation of pure oxygen, they say, could meet shortages in supplies at hospitals.

At present, the nanomaterial can only be produced roll-to-roll in a pilot line, but it could be scalable for industrial production, suggests Yang.