Mixing metals with elastomers for new biomaterials

Using metal chelation as the cross-linking mechanism offers a versatile take on biodegradable elastomeric biomaterials.

Initially the team wanted to add copper to the polymeric material, poly(propanediol-co-(hydroxyphenylmethylene)amino-propanediol sebacate), to aid blood vessel formation for tissue regeneration. But researchers have also tested the elastomer with calcium, magnesium, iron, zinc and cobalt. ‘I am confident many others can be used, titanium, chromium, etc’, says Yadong Wang, Professor of Cardiac Assist Technology at Cornell.

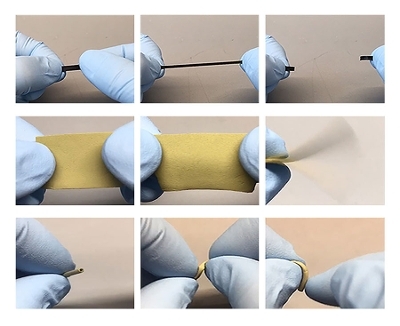

The polymer is cross-linked by metal ions through chelation bonds to form the elastomer, Wang explains. With chelation bonds having a moderate strength and the elastomers having several cross-linking bonds, all the chelating ligands form a strong molecule.

‘It’s a versatile platform’, notes Wang. ‘We just put in different metal ions. […] we used six biologically relevant metal ions for the single

ligand-containing polymer. One can expand this beyond the six metal ions and create many more just based on this single polymer,’ he explains.

‘We tested the mechanical properties and a few of the elastomers show very high elasticity, i.e. low plastic deformation even after 100s of cycles. We tested biocompatibility with tissues just under the skin, the material induced milder inflammation than PCL, a polymer already used in humans.’

He explains that currently the team is focusing their efforts on biomedical applications which include making artificial blood vessels, ligaments and skin. However, he also sees potential for use in food and even the rubber industry.

‘We are exploring different ways to process it. I believe we can soon test its application as a vascular graft,’ Wang shares.

He adds that before large scale roll-out can be achieved, the team needs to demonstrate utility, advantage over existing approaches and scale up the synthesis.