Microbial weaving produces textiles

UK biotechnology company Modern Synthesis has developed a biomaterial using bacterial fermentation that it believes offers a low-carbon alternative to traditional clothing fabrics.

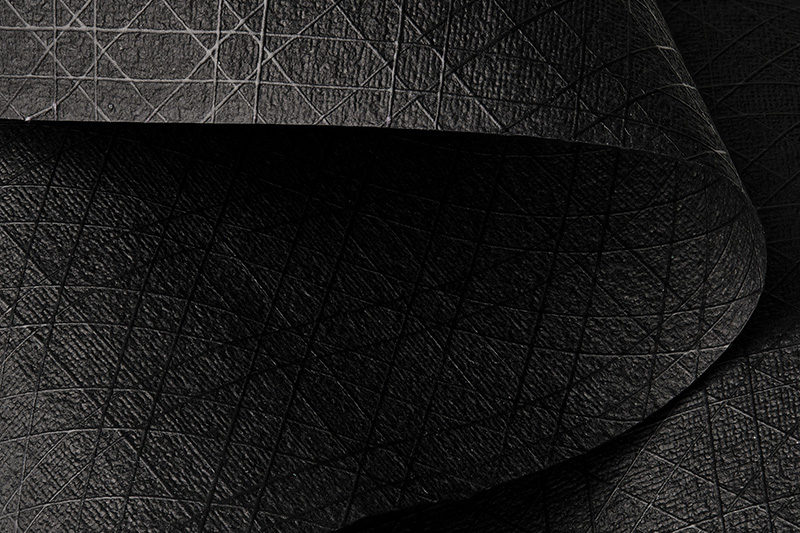

Based in London, the firm was inspired by the natural growing behaviour of a bacteria called K. rhaeticus. In the product, they grow nanocellulose on a framework of thread using bacteria that consumes sugar byproducts from other industries. A warp pattern or scaffold, created using robotic yarn or fibre placement, enables the bacteria to grow nanocellulose around it for a new type of fabric that exploits nanocellulose’s well-proven strength and stiffness coupled with light weight and low density.

The bacteria K. rhaeticus is reported to produce cellulose at such a small scale that the fibres are strong and bind to each other naturally. This reduces the need for chemical crosslinkers currently used by industry. The firm explains that it is unusual for a textile to be both lightweight and extremely strong, opening up applications within industry (e.g. aerospace etc).

Sarah West Young, Head of Growth at Modern Synthesis, says, 'The nanocellulose fibres produced by the bacteria have a unique strength…and ability to bind to themselves to form strong nanostructures without the use of harsh chemicals or synthetic binders.

'We are uniquely able to form these nanofibre structures around a natural textile scaffold (usually hemp, linen or lyocell) to create an entirely new class of natural nonwoven materials.

'Similar to how rebar is used to reinforce concrete, the textile reinforces the nanofibre matrix but also enables a huge range of flexibility in the final material’s look and feel.'

The resulting textile, the company says, can be processed on the same equipment as conventional textiles and naturally derived coatings can add functionality.

Modern Synthesis points to a number of benefits of using bacteria for this purpose. These include efficiency of production. Unlike other cellulosics (like cotton), which grow in fields over months or years, they explain that the bacterial nanocellulose can be grown in bioreactors in days, with very few inputs. This evolving biotechnology platform means materials could be ‘tuned’ to meet the needs of a variety of product applications and aesthetic preferences.

Young says, while they have not yet done a full lifecycle assessment (typically done at manufacturing stage), a preliminary third-party assessment suggests greenhouse gas emissions could be up to 65 times lower than leather, and up to two times lower than petrochemical-based textiles.

She notes the microbes can digest any kind of agricultural waste feedstocks. 'Our textiles reduce input waste and enable a decentralised manufacturing system' that takes up less space than farms or chemical plants.

Modern Synthesis stems from co-founder Jen Keane’s Master’s project at the University of Central Saint Martins in London.

During this work, she met co-founder Dr Ben Reeve, who discovered and sequenced the strain of bacteria they now employ to produce the biomaterials.

They have just created a class of microbial biomaterials that they say can mimic a wide spectrum of textiles.

Their focus over the next three quarters will be generating more materials for trials with leading brands to optimise characteristics for specific product applications. They are also looking to scale production capacity.