Mechanically imprinting dislocations in electroceramics

Dislocations are being mechanically imprinted into single-crystal bulk ceramics to enhance their electromechanical properties.

Researchers from the Technische Universitat Darmstadt, Germany, suggest that such dislocations effectively interact with ferroelectric domain walls on an atomic scale, as well as affecting the macroscopic domain structure and increasing the piezoelectric coefficient.

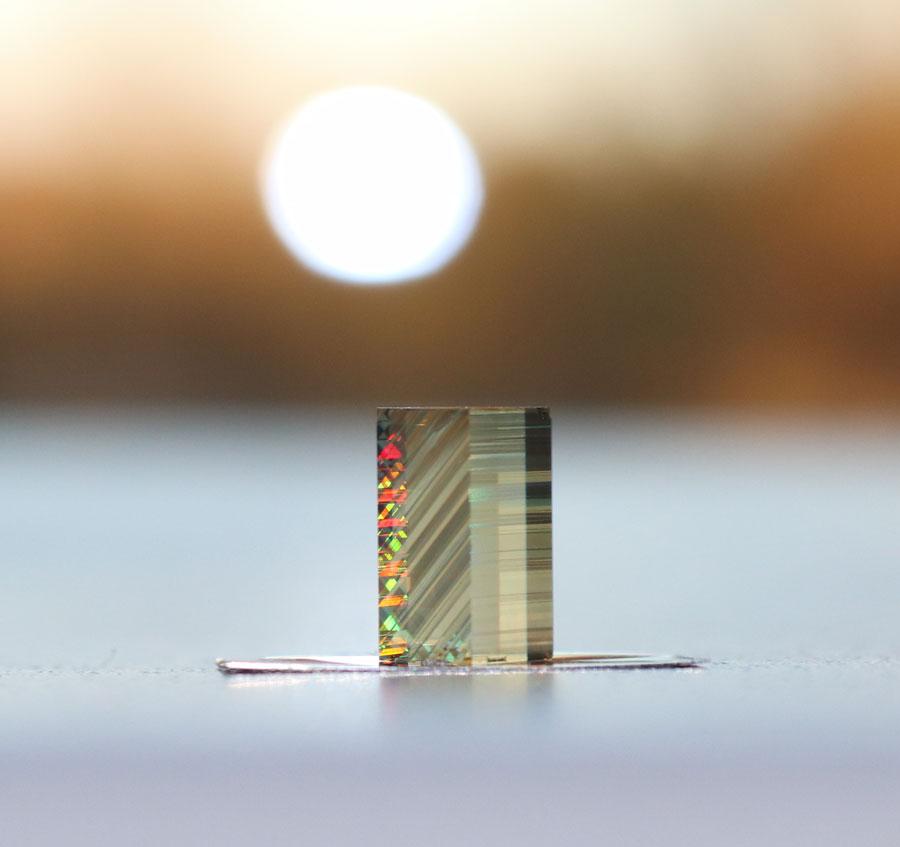

They have tested this on barium titanate (BaTiO₃) as it allows dislocations to be introduced into the material, limited by the available and active slip systems, while also having a non-centrosymmetric structure for piezoelectric behaviour.

‘The location and distribution of the dislocations in the material (and thus of the atoms) is based on the existing slip systems, which in ceramics are limited by ionic and covalent bonds…The basic idea was to find a new method to modify the motion of the ferroelectric domain walls, since this is crucial for the electromechanical performance of the material,’ says Marion Höfling, Researcher at the University.

‘The concept is based on the mechanical imprinting of dislocations into the ceramic, which is a new approach in the field of functional ceramics.’

The ceramics are mechanically deformed under controlled pressure and temperature conditions so the displacement can be imprinted. The team explains that, until now, it was largely deemed impossible with ceramics because of their hardness and brittle surface. To overcome this, a mechanical imprint is made at 1,150°C in a single crystal in a previously calculated optimised orientation.

This method now allows a well-ordered field of newly occupied atomic rows. These series control the local polarisation – the load dislocation – in the material. In the operation of electroceramics, the material areas now delimited by the series (displacements) take up certain charge shifts, and as these material areas do not change under high operating conditions, no energy is converted by internal friction and the material behaviour remains stable.

Höfling continues, ‘Modification of electromechanical properties in functional ceramics such as piezoelectric and ferroelectrics is usually based on point defect doping or chemical modifications, which are 0-dimensional defects. Therefore, considering dislocations as possible stabilising defects in a material commonly considered ‘brittle’ is a new perspective. In contrast to point defects, dislocations have the advantage of being more temperature stable, exhibiting good cycling stability, and requiring less complex chemical compositions due to the fact that line defects are intrinsic defects.

‘The basic concept of dislocations (Burgers vector, screw and edge type, etc.) is the same as in metals with the difference that the dislocation core can be charged and that they may have a charged space charge zone in the surrounding.’

Höfling explains that the mechanical dislocation imprint for functional property modification is inspired by plastic deformation in metals, creep studies in geology, and defect engineering in piezoelectric and ferroelectric oxides.

She notes that electroceramics fabricated using standard approaches often have some drawbacks in performance or secondary requirements such as cycling and temperature stability.

The scientists have tested the dislocations with transmission electron microscopy and phase field simulations. They are currently seeking to implement it in polycrystalline materials to allow easier transfer to real applications.

Höfling concludes, ‘The goal of this basic research is that in the future materials can be modified to replace some of the commonly used toxic piezoelectric materials with even better properties.

‘A five-times increase in dielectric properties and almost 20-times increase in piezoelectric performance, enables [us] to make more efficient (and thus smaller) dielectric capacitors and piezoelectric motors.’