Magnetically modifying metamaterials for extra strength

The mechanical properties of a metamaterial are being reprogrammed by applying a magnetic field.

By increasing geometrical complexity and decreasing material complexity, researchers from the École polytechnique fédérale de Lausanne (EPFL), Switzerland, say the material can display a range of physical properties, like stiffness and strength, so that the materials do not have to be replaced.

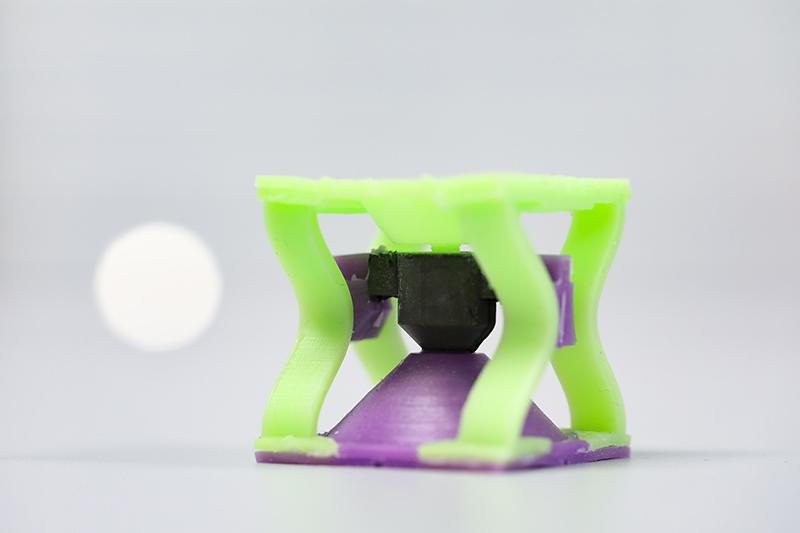

Made of silicone and magnetic powder, the cells within the structure behave like an electrical switch.

The internal geometry is designed to achieve three things: 1) Change the unit cell geometry between two states through an external magnetic field. 2) Make the state change stable, i.e. when the field is turned off, the change stays. 3) The two states exhibit significant differences in mechanical quantities.

‘Therefore, we included a magnetorheological elastomer (MRE), as well as a bistable shell in every unit cell,’ says Tian Chen, Scientist at EPFL.

‘The magnetic field, when turned on, exerts a force through dipole interaction on the MRE within each unit cell. This pushes or pulls the bistable shell to another state. To reverse this, we just reverse the current on the field.

‘In this work, we in a sense go beyond traditional metamaterial design,’ he adds. ‘With [previous] metamaterials, once fabricated, their properties can no longer be changed. Instead, we provide a template material whose properties can be programmed on-the-fly and repeatedly.

‘You can activate and deactivate individual cells by applying a magnetic field. That modifies the internal state of the metamaterial and, consequently, its mechanical properties,’ says Chen.

The programmable material is analogous to computer devices, which contain bits of data that can be written to and read from in real time. Chen explains that the cells in the metamaterial, called m-bits, work like the bits in a hard drive – they can be switched on, making the material stiffer, or off, making it more flexible. This would allow researchers to programme various combinations on and off to give the material exactly the mechanical properties they need at any given time.

‘Using running shoes as an example, one typically needs one pair of shoes for indoor running and another for outdoor, yet another for trail running,’ Chen notes. ‘If we are able to adjust the stiffness of the shoe soles, we may be able to reduce this to just one pair.’

Other potential applications include devices where on-the-fly modification of stiffness and energy absorption is a benefit. ‘For example, limp braces or mechanical shock and vibration absorbers. From a boarder perspective, the notion of stable encoding of material properties can be extended to many other domains, for example, attenuation of earthquake waves,’ Chen offers.

The team will now explore micro-fabrication techniques to make similar structures at a much smaller scale with many more unit cells.