In full measure - the Metrology Technician apprenticeship

With the first group of apprentices having completed the Metrology Technician apprenticeship, we scope out the course’s delivery.

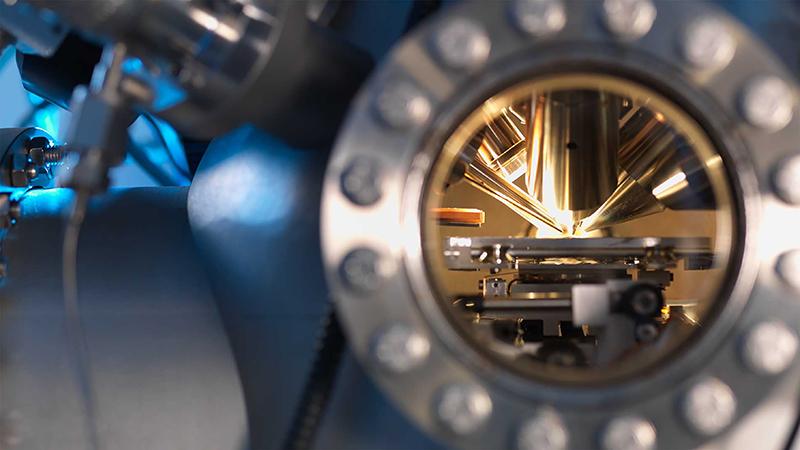

Metrology – from the Greek words metron and logos – is the essential scientific study of measurement. Metrology skills are in high demand, with 75% of managers in industry telling a National Physical Laboratory (NPL) survey that they would use an apprenticeship in measurement to recruit, train and develop their employees.

It is a reason why, in 2017, the first ever Metrology Technician apprenticeship curriculum was developed by the UK’s NPL and delivered by manufacturing trade body Make UK. ‘NPL ran numerous courses in metrology, but there was never a recognised standard,’ notes Neil Ellor, Industrial Training Manager at Make UK.

Following input from employers across the manufacturing industry, NPL developed the apprenticeship curriculum to enable a new pipeline of sought-after talent to employers, contributing to the long-term success of the metrology profession and the economy. The first cohort of nine apprentices have since graduated from the course, which runs for two and a half years.

The Standard was created to give apprentices both the knowledge and skills to undertake a career in metrology.

Ellor explains, ‘We have found that this apprenticeship works best for [people] who are already in engineering and want to broaden increase their skills. The standard is very broad, so after the apprenticeship, the apprentices could work in a variety of engineering fields using their skills to check the quality of products for a wide range of companies.’

There are 18 units to be completed and these are delivered one day a week with projects also carried out in the workplace. Units cover a breadth of topics including health and safety, Système international units, units of measurement, measurement uncertainty, calibration and traceability, statistical process control, and measurement system analysis.

One of the students, David Taylor, says, ‘I was given the opportunity to take part in the first metrology apprenticeship course hosted by Make UK. The course was mainly classroom-led, but we got the chance to do our own experiments and even visit NPL. The beginning of the course was tough going, as metrology covers a lot of different subjects. With the help of the tutors, things started to fall into place. I especially enjoyed doing my own Type A and Type B R&R studies – this helped me get a better understanding of Process Performance and Capability (Cp, Cpk, Pp and Ppk). Overall, even though the course was difficult, I'm glad I took part as I feel more confident as a measurement technician and pleased to have the qualification behind me for life.’

Make UK now hopes to become the centre of excellence for metrology in the Midlands. NPL has also developed free e-learning taster courses for future apprentices.