Hybrid Steel reported to resemble stainless steel

Steel manufacturers Ovako in Sweden report results from laboratory tests that suggest their Hybrid Steel product shares similarities to stainless steel, despite its unusual make-up.

The tests, including electrochemical measurements, have found commonality in terms of passivity, breakdown and pitting to a low-alloyed stainless steel. This is despite the level of chromium being well below that of a traditional stainless steel.

Aluminium and nickel in Hybrid Steel has been found to enhance the role of chromium in forming a spontaneously passive and protective surface, leading to 'exceptional corrosion resistance in acidic and chloride-containing solutions', says the firm.

Dr Steve Ooi, a Group Technical Specialist with Ovako and based at Cambridge University, UK, conducted the tests.

He reveals that Hybrid Steel’s surface oxides remain robust even beyond the Cr(III)-to-Cr(VI) redox potential, distinguishing it from other stainless steels. This demonstrates the potential for stainless steel with high-strength properties without needing to be under the previous conventional minimum threshold of 10.5% chromium. Ovako’s three variations of Hybrid Steel all contain 5% chromium.

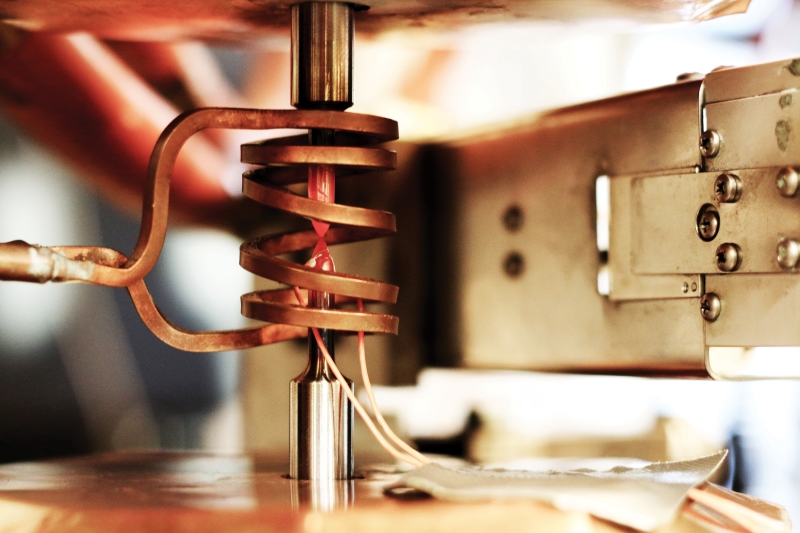

Hybrid Steel was introduced in 2017 to combine two well-established hardening mechanisms – carbides and intermetallic precipitations. The aim was to meet the demands of high-stress, elevated-temperature applications where mechanical and fatigue strength are critical.

It is an alloy steel with chromium, aluminium, nickel, vanadium and molybdenum added to achieve its mechanical and corrosion properties.

Hybrid Steel reportedly develops its full properties after tempering at temperatures of around 500-600°C with low distortion. Ooi explains how manufacturers can eliminate production steps with materials such as Hybrid 50, which does not need to be soft annealed for machining because of the low amount of carbon added. He notes that it also does not need to be reaustenitised after the machining process and can be aged to increase the steel’s strength to above 1,500MPa with minimal distortion.

'Even though the microstructure is considered martensitic in as-forged/as-rolled conditions, it is soft enough and is suitable for machining. The ageing process induces the precipitation of nickel-aluminium intermetallic that strengthens the steel. Hybrid Steel 55 and 60 would require hard machining to reduce process steps,' adds Ooi.

'Typically, the Hybrid Steel (55 and 60) is supplied in soft annealed condition for our customers. After machining, the steel can be hardened to the required strength via austenitisation, air cooling and tempering.'

Hybrid Steel is made from recycled iron and steel, and Ooi suggests that due to its elevated temperature microstructure stability, it is expected to have a longer lifespan.

Also see Materials World, July/August 2023, for an article on how Ovako is switching to hydrogen.