Divertor takes the heat for future tokamak fusion machines

Scientists at the UK Atomic Energy Agency (UKAEA) claim to have successfully tested a divertor that removes excess heat to enhance the durability of future tokamak fusion machines.

Dr Andrew Kirk, UKAEA Lead Scientist at the Mega Ampere Spherical Tokamak (MAST) Upgrade project, explains that the Super-X divertor, made from carbon for its hard-wearing and robust properties, reduces the heat from a blowtorch level down to that produced by a car engine. ‘This could mean it would only have to be replaced once during the lifetime of a power plant. What we have done with the Super-X divertor is to make the exhaust pipe longer. This means the excess heat travels further and has time to cool down to acceptable levels by the time it comes into contact with the surfaces in the divertor.

‘We also inject a gas in the divertor to spread the heat out over a wider area. A combination of these two things produces the effect we are looking for.’

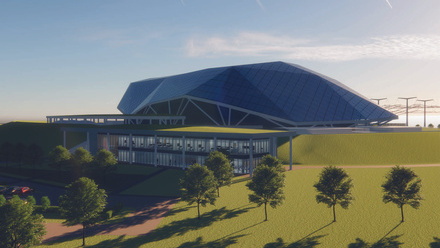

UKAEA is currently designing a prototype fusion Spherical Tokamak for Energy Production (STEP) – this MAST Upgrade device will be a key component. Kirk adds, ‘Via its STEP programme, UKAEA is now designing a spherical tokamak power plant with the target of producing electricity by the early 2040s. The early results from the Super-X divertor indicate that it could be used as an exhaust system for STEP, which is positive news.’

The MAST Upgrade – the UK’s national fusion experiment – is located at Culham near Oxford, UK, and is demonstrating the novel exhaust system to make compact fusion power plants commercially viable. The results reported have been a long time coming, explains the team behind it.

The MAST Upgrade device is an evolution of the MAST spherical tokamak, which UKAEA operated between 2000 and 2013. MAST Upgrade uses a similar design but is said to be capable of much higher performance.

In March 2014, the rebuild began and the machine was complete and ready for commissioning in 2018. The first ‘plasma’ test was achieved last autumn, with these first results from the Super-X divertor this year.

For a plasma typically 100mlnoC, the team has measured the heat arriving at the divertor in a conventional configuration and in a Super-X configuration.

‘We run tests at MAST Upgrade numerous times a day – every 20 minutes or so – and each test or ‘pulse’ lasts for between 1-5s. After each pulse we can measure the heat load that has gone on to the divertor surfaces, which gives us a good indication of how effectively the exhaust system is working,’ says Kirk.

He explains that the measurements show that the heat arriving at the surfaces in a Super-X configuration are reduced by at least a factor of 10, relative to the conventional configuration. ‘This was exactly in agreement with the modelling predictions that we had used to design the machine.

‘We will continue to investigate the benefits of the Super-X divertor and explore ways of improving the technique still further, including looking at different materials. We will combine experimental data with modelling to allow us to improve our predictions for future devices.’

At the time of writing, the initial list of sites being considered for the STEP plant were published. Assessment has now begun of the proposed sites. Many sites have adjacent operations, bringing mutual dependencies if STEP were to be developed in those locations. The shortlisting phase will take place in the autumn.

A final decision is anticipated around the end of 2022.