Constructing a better future

Will Arnold, Head of Climate Action at the Institution of Structural Engineers, talks about the role construction materials play in climate and ecological breakdown, and proposes the next steps for a sustainable built environment.

In an era of heightened environmental awareness, the responsibility for mitigating the impacts of construction materials lies squarely on the shoulders of all those involved with their specification, production and use.

Society is now well-aware that climate and biodiversity breakdown is real, human-induced, and of significant consequence – and are now looking to industries like ours to provide the solutions to regenerating our environment and climate. After all, if we are aware of the damage that human activity is causing to our environment, and choose not to act, then how will we possibly answer to our children when they question what we were doing at this moment in time?

What role have construction materials played in climate and ecological breakdown, how do they affect society, and how can we play our role in ensuring that, in the future, our use of construction materials is wholly positive?

Creating the built environment

Humanity’s ever-growing collection of buildings and infrastructure exists to support human wellbeing. We have built towns and cities full of homes, schools, hospitals and offices, connected together with a network of transport and energy infrastructure, to keep everything running smoothly.

We have done this with materials that are strong, durable, plentiful, economical, beautiful, and can be used in a myriad of different ways – and so, we have filled our world with them.

When we need more, we create more. When something old and less useful stands in our way, we discard it and build something new. We do this with good intentions, but we have become so efficient at this that, according to one study published in Nature, the total weight of all human-made material on Earth is now greater than the total weight of all the trees, animals, vegetables, and other living things on the planet combined.

Assessments vary as to what proportion of this is due to the construction materials used in the built environment, but my estimate is just short of 98% – after all, there are few things as heavy as a building, bridge or road!

There are benefits to this – build a road, and you connect communities. But there are also downsides – you generate emissions, destroy habitats and disrupt communities.

And the balance of impact depends on the situation. If we use a small quantity of resources to create a road to join a disconnected community to the amenities of a large town, we transform people’s lives with little environmental impact. However, if we use a far larger quantity of resources to upgrade a small road into a seven-lane highway, perhaps the balance shifts.

Creating a much-needed building might support human wellbeing at that location, but the built environment as a whole is only supporting global wellbeing if it is taking care of the entire global ecosystem that humanity is a part of. This means understanding and reversing emissions, biodiversity loss and societal damage all over the world.

Impacts

According to the UN 2022 Global Status Report for Buildings and Construction, in 2021, around 15% of global greenhouse gas emissions came from the production and use of the ‘big five’ construction materials (concrete, steel, aluminium, glass and brick), with nearly 5Gt of CO₂e resulting each year from the construction of buildings, and another 3Gt from infrastructure.

These figures are not expected to decrease any time soon. My analysis of the UK steel and cement industries’ decarbonisation roadmaps indicates emissions reductions of 25% by 2030, far short of the 50% reduction called for by the Intergovernmental Panel on Climate Change for the sector to align with a 1.5°C trajectory.

Of even larger concern, though sadly less well-understood at present, appears to be the built environment’s impact on biodiversity loss. The World Economic Forum highlights that the built environment is helping to endanger 29% of species that are already threatened or near-threatened around the world.

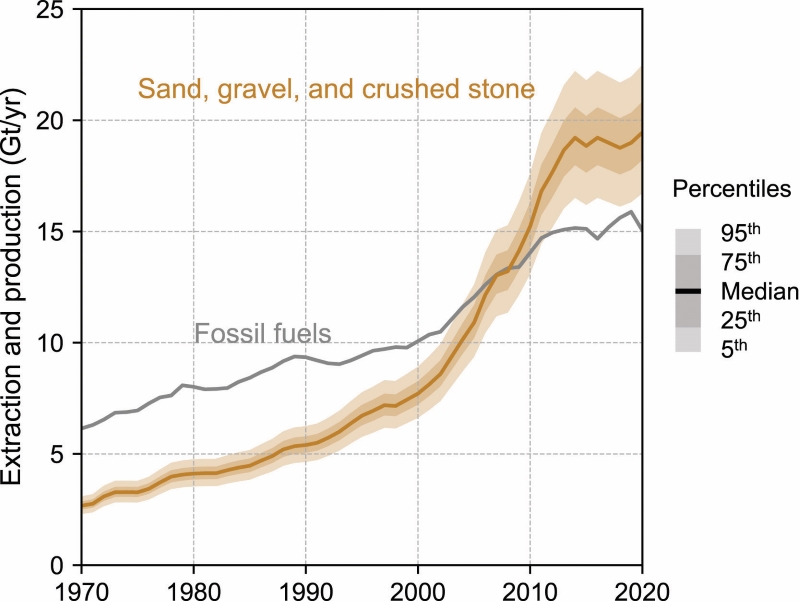

This is not a surprising statistic from the most material-intensive sector in the world – the image below shows how the extraction of aggregates alone has outpaced even the extraction of fossil fuels for over a decade now.

Recent studies by Expedition Engineering and the UK Green Building Council highlight the resulting habitat destruction, land use, and pollution across air, soil and water that results from construction materials. The Embodied Biodiversity Impacts of Construction Materials report starkly notes that, “None of the materials or processes were assessed to have significant positive impacts on biodiversity”.

Finally, when it comes to the impact on society, many assume the resulting cities and infrastructure have a positive impact. However, the International Labour Organization states around a quarter of a billion people working in the sector – 7.7% of global employment – meaning there are many instances where the impact on some people is far from positive.

In Sand Stories, Kiran Pereira lays bare the impacts that come from illegal mining operations to extract sand for use in concrete and glass production. Such impacts can extend beyond extraction practices – for example, human rights abuses reported during the Qatar World Cup are still not yet resolved, with thousands of construction workers reported to have died in the country since it was awarded the competition.

These three areas of impact paint a pretty bleak picture. While we have set out to help create a built environment that can benefit society, we are now waking up to the fact that in doing so, we continue to cause significant environmental and societal damage around the world.

Gaining a clearer picture

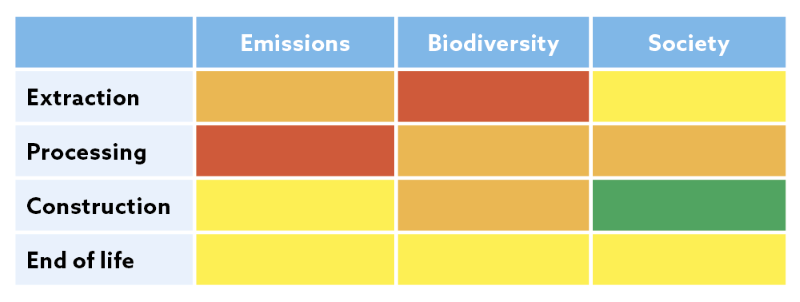

To undo such damage and start to repair and regenerate the world, we must first understand the specifics of how each material impacts climate, biodiversity and society by looking at the four stages of a construction material’s life:

- Extraction of raw minerals and ores

- Processing to create construction materials

- Construction of buildings and infrastructure

- End-of-life waste generation

Further impacts occur due to transportation between each step.

Different materials lead to different types of impact, in different places, at different times. For example, while most biodiversity impacts occur during the extraction of raw minerals and aggregates (stage 1), greenhouse gas emissions are mostly released during processing (stage 2).

A government can protect its own construction workers with the most stringent employment rights in the world (stage 3), but if they send their construction waste abroad, then they lose control over the societal impacts resulting from demolition and waste processing (stage 4).

Such impacts need to be understood and mapped out for each material that we work with so that specifiers and suppliers understand how best to intervene to change harmful stages into helpful ones.

The table below is an example of mapping such impacts for a notional construction material. The person undertaking mapping would be able to identify where emissions can be reduced during processing, and tackle biodiversity loss during sourcing. Similarly, they could then repeat the mapping exercise for changes to their business model – perhaps switching to recycling waste materials, or even using reclaimed materials without processing – to understand how such decisions could improve impacts.

Most specifiers of materials would currently struggle to complete such a mapping due to the complexity of supply chains. Perhaps this is the biggest immediate opportunity for those working in materials supply – to identify and report the impacts (positive and negative) coming from the entire supply chain, transparently and honestly.

From “less harm”…

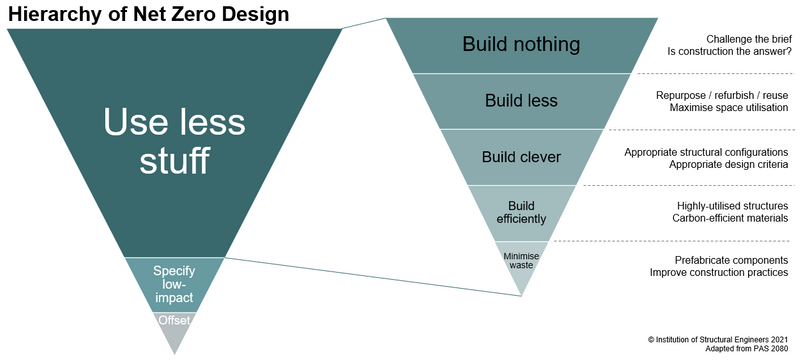

Once we understand the impacts of our materials, we then need to decide what to do about them. The Institution of Structural Engineers advocates that its members focus on a hierarchy intervention based on using less new material altogether, in response to the slow pace of material decarbonisation and the worrying fact that most suppliers have yet to start tackling biodiversity impacts.

Reduction in material use and therefore demand might worry those whose companies supply construction materials. They might assume this would lead to a downturn in income and profits, but this doesn’t have to be the case. There are plenty of examples of the exact opposite happening. Take bicycles and smartphones for example – consumers will happily pay more for the lighter, slimmer version of each.

Similarly, structural engineers today are under huge pressure to deliver schemes that result in lower environmental impact – if you can provide them with a solution that reduces material use, the client will likely be happy to pay for this.

The ACORN research project based at the Universities of Bath, Cambridge and Dundee, UK, recently produced a vaulted precast floor slab using less than half the amount of concrete in a typical floor slab.

Similarly, steelmakers that produce higher strength steels, for the same levels of emissions as traditional 355MPa steel, are finding a new market from those looking to use less material for strength-governed structural elements such as trusses and columns.

This is an opportunity for those involved in materials supply chains to work more closely with product manufacturers to transform their businesses in ways that will reduce negative impacts while delivering high-value materials to end-clients.

...to “more good”

Reducing negative impacts is of course a good first step, but is it enough? After all, annual global emissions are 50Gt higher than they need to be by mid-century, and we have lost 69% of our biodiversity in the last 50 years. Can we undo these statistics by doing “less harm”?

When you were younger, you might have been left alone with a free house for the weekend. If like me, you took such opportunities to throw a party, then you probably can remember how it feels to wake up the morning after, to a hangover and a messy house. You realise, in a panic, that your parents are on their way home, and that you urgently need to deal with the mess. In such a situation, I don’t suppose you were proposing a strategy of “making less mess” to your friends. More likely, you turned things around completely and started cleaning up.

Of course, for this metaphor to really make sense, we should recognise that our current situation is more akin to the parents staying home and messing the place up, and waking up in a panic that their children are the ones about to discover what they’ve done. But either way, I think you probably see the point.

There is an ongoing awakening to the reality of climate and biodiversity breakdown. If we are to repair, restore and regenerate the natural world that we inhabit, then we are going to need to turn things around completely and start cleaning up.

It is for this reason that instead of a goal of “do less harm”, we instead need to have one of “do more good”. While more efficient use of materials is an important first step to take, we need to go further. There is a huge business opportunity to create brand new materials for building designers to use – “use less stuff” is soon reversed if the material being used has a wholly positive impact on the environment, ecology and society.

The biggest opportunities lie in a more radical transformation of today’s materials – away from business models reliant on the extraction of raw materials, and towards ones that start to draw down on the millions of tonnes of waste created each year, or models that start absorbing greenhouse atmospheric pollutants.

The industry is beginning to get really excited about new concrete technologies promising to absorb emissions from the atmosphere during their creation, such as Seratech and Brimstone. In Sweden, the world’s first fossil-fuel-free iron was produced in 2022, and producers of bio-based materials continue to focus on the atmospheric benefits of locking CO₂ away for decades in a building.

Another great example of material transformation is the current momentum in the UK built environment to embrace the benefits of a circular economy. At City Place House in London, 1,500t of steel have been recently removed from a building cited for demolition, and are now being cleaned, repainted and recertified, so that they can be used across a number of new projects overseen by the same client.

At the École Polytechnique Fédérale de Lausanne in Switzerland, researchers have built a footbridge over a river using reclaimed concrete from a wall that they cut into discrete blocks. While in San Francisco, engineers are using artificial intelligence and robots to ready reclaimed timber for reuse in new construction projects. The Institution’s guide, Circular economy and reuse: guidance for designers, contains numerous more examples of live projects successfully reusing products and materials.

The RE:CRETE footbridge at EPFL, Switzerland, was built from concrete previously considered ‘waste’

© Devènes, J., Brütting J., Küpfer, C., Bastien-Masse, M., Fivet, C., Re:Crete – Reuse of concrete blocks from cast-in-place building to arch footbridge (2022) Structures doi.org/10.1016/j.istruc.2022.07.012 http://creativecommons.org/licenses/by/4.0Mainstreaming of materials built from waste, regrown materials, or from carbon taken from the atmosphere, could herald a revolution that finally sees construction materials start to do more good.

As investors continue to increase interest in emissions and environmental, social and governance reporting, you can guarantee that it is the material supply chains who embrace these new business models that stay relevant and profitable. Clients want materials that demonstrate removal of emissions, removal of pollutants, increases in nature and societal benefits in the least resilient parts of the world.

If suppliers can provide these new materials, then designers will race to bring them onto projects. The Institution’s new book, The regenerative structural engineer, challenges engineers to design in a way that enables human and other living systems to survive, thrive and co-evolve together. We cannot do this without construction materials that have a wholly positive impact.

We need a material revolution.