Composite combines high electrical and low thermal conductivity

A flexible composite is reported to display the unusual combination of high electrical conductivity and extremely low thermal conductivity.

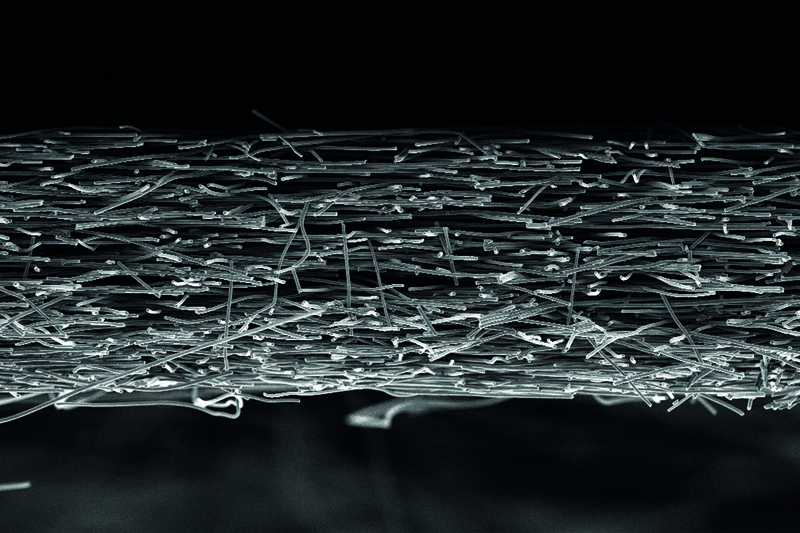

The nonwoven fibres, created at the University of Bayreuth, Germany, are made from an electrospun carbon and silicon-based ceramic. The team thinks they are attractive for areas such as energy technology where multifunctional materials that have good electric with low thermal transport are in demand.

The material is made of a commercial polyacrylonitrile copolymer and an oligosilazane precursor, and the team believes it can be manufactured and processed cost-effectively at scale.

Achieving high electrical conductivity and low thermal conductivity has previously been a major challenge for flexible and foldable materials. Normally, high electrical conductivity is associated with high thermal conductivity, and low thermal conductivity with low electrical conductivity.

This material consists of fibres with a ‘sea-island type’ nanostructure, which are 500-600nm in diameter. Each fibre contains a carbon matrix in which nano-sized ceramic phases are homogenously distributed, and the particles form tiny ‘islands’ in the sea of carbon. While the carbon matrix enables electron transport and high electrical conductivity, the nano-sized, silicon-based ceramic prevents thermal energy spreading.

Corresponding author Dr Seema Agarwal notes that they have achieved thermal conductivity of 19.8 ± 7.8mW/m/K (cross-plane, lower than air) and 31.8 ± 11.8 mW/m/K (in-plane), and an electrical conductivity of 4.2S/cm (in-plane).

She explains that this is because the interface between the two materials is 'very high' due to the large surface area caused by the nanostructure. The pores of the nonwoven fibres are meanwhile small, leading to a scattering of phonons – the smallest physical units of vibrations triggered by thermal energy. As such, continuous directed heat flow does not occur.

Agarwal adds, 'These nonwovens have good fatigue tolerance, sufficient mechanical resilience and foldability. A 5,000-cycle folding-unfolding process did not break the fibres and introduced a negligible change in the electrical resistance variation. When we light a LED lamp by using our flexible nonwovens as an electric conductor, the brightness of the LED lamp visually did not change during bending, twisting and folding operations.'

A limiting oxygen index test determines the relative flammability by burning a sample of the material in a contained environment with oxygen and nitrogen gases and reducing it until combustion cannot be sustained. The researchers report their nonwovens as being non-flammable as they can withstand a 100% O₂ atmosphere.

The unusual combination is highlighted by a comparison with more than 3,900 materials – including ceramics, natural materials, carbons, polymers, metals and various composites. Electron transport and thermal energy insulation were found to be the most linked in the new composite.

First author Dr Xiaojian Liao comments, 'Our electrospun nonwovens combine highly attractive multifunctional properties that are usually distributed among different classes of materials: high electrical conductivity, thermal insulation familiar from polymer foams, and the non-flammability and heat-resistance characteristic of ceramics.'

'We are convinced that our new fibres are suited for several application areas – for example, in the fields of energy management, battery-powered electromobility, smart textiles, or aerospace,' says Agarwal. She believes scaling up is eminently feasible as electrospinning is a continuous and industrialised production method for nonwovens.