Ceramic origami design bends under pressure

The origami shapes with a soft polymer coating can reportedly transform fragile ceramics into tough, flexible structures.

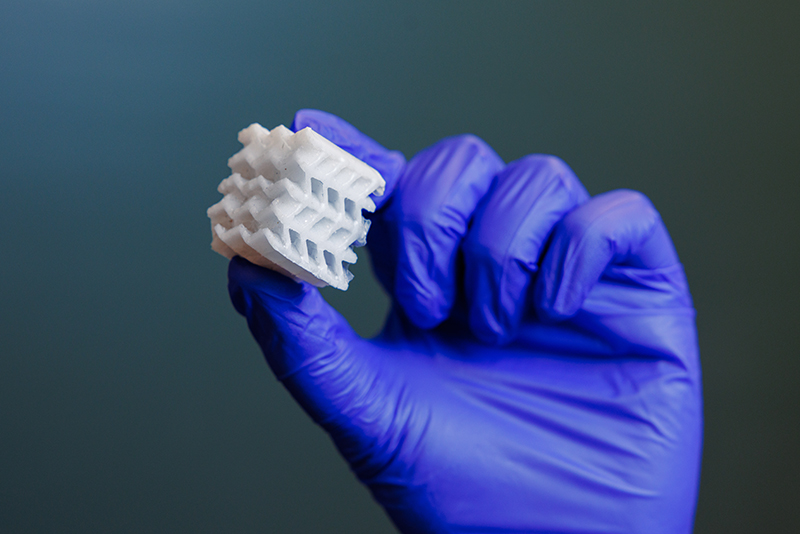

A team at the University of Houston, USA, 3D printed the ceramic structure based on the Miura-ori origami pattern – a way to fold something flat, like paper, so it takes up less space but stays flat – and then coated it with stretchable, biocompatible polymer polydimethylsiloxane (PDMS).

The invention was inspired by the structure of nacre in molluscan shells – mother of pearl.

Nacre combines brittle aragonite platelets with thin layers of soft organic material in between. These soft layers absorb stress and prevent cracks from spreading, allowing gradual failure.

The researchers report the new ceramic design can handle stress in ways ordinary ceramics cannot. It has higher damage tolerance, a graceful failure mode, higher energy absorption and survives multiple cyclic loadings.

Maksud Rahman, University of Houston, says, 'The Miura-ori structure provides geometric toughening, anisotropy and orientation-dependent stiffness.

'The flexible PDMS coating on the Miura-ori architecture arrests cracks, preventing crack propagation within the structure. The coating reduces tensile damage parameters, particularly at the crevices. It distributes stress away from the crevices, preventing stress concentration, thus preventing catastrophic failure.'

He continues, 'The coating in architected ceramic structures is particularly effective in distributing away tensile stress, preventing tensile stress concentrations.'

When compressed in different directions, the coated structures flexed and recovered, while their uncoated counterparts cracked or broke.

The researchers have tested the structures under both static and cyclic compression, and backed up their experiments with computer simulations.

The coated versions consistently show greater toughness – especially in directions where the original ceramic was weakest.

In the X orientation, the uncoated ceramic origami structure endures 1,500N, while the coated material handles 1,696N. In the Y orientation, the uncoated structure endures 2,999N, while the coated material handles 3,192N. Finally in the Z orientation, the uncoated structure endures 7,826N, while the coated material handles 9,253N.

The future of this research would be to achieve maximum possible 2D-to-3D bendability for brittle materials like ceramics, according to Rahman.

They plan to tweak the origami pattern design – adjusting angles and panel sizes, for example – to make the ceramic structures more flexible for specific uses.

They are also interested in using AI-based algorithms to optimise the designs.

The goal is to create customised, lightweight, ceramic structures that can handle stress better, which could be useful in everything from protective gear to aerospace components.

The key challenge in scaling up is the viscosity of the ceramic resin.

The Formlabs ceramic resin is an experimental resin, and due to the silica particles dispersed in it, its viscosity is high. This would make it challenging to print sizeable and complex architectures with this resin, particularly in large volumes. Modifying the ceramic resin or formulating a new ceramic resin is key for future research.

Rahman adds, 'Our group had previously shown that conformal coatings can improve damage tolerance in 3D-printed ceramics. This work advances that idea by combining it with the 3D Miura-ori geometry.

'PDMS-coated ceramic is biocompatible and has many applications in prosthetics and biomedical engineering.'