Can wearable electronics biodegrade?

Are sustainable, wearable electronics too good to be true?

‘For the first time, we have demonstrated that it is possible to produce sustainable [electronic wearable] displays that are largely based on natural materials with the help of industrially relevant production methods,’ claims Manuel Pietsch, Researcher at the Karlsruhe Institute of Technology’s (KIT) Light Technology Institute, Germany.

‘After use, these displays are not electronic scrap, but can be composted. In combination with recycling and reuse, this might help minimise or completely prevent some of the environmental impacts of electronic scrap,’ adds Pietsch.

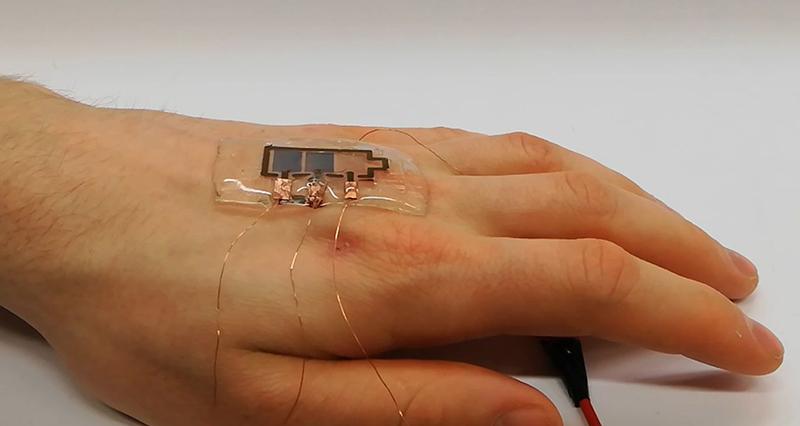

The KIT researchers have fabricated the displays by exploiting the self-adhesive properties of gelatin hydrogel, so it can be worn innocuously on the skin without loss of performance. The team suggests the research has potential for use in optoelectronic systems.

According to the study, Biodegradable inkjet-printed electrochromic display for sustainable short-lifecycle electronics, published in the Journal of Materials Chemistry C, the natural and biocompatible materials used to develop the display include a poly(3,4-ethylenedioxythiophene), polystyrene sulfonate (PEDOT:PSS) electrochromic layer, a gelatine-based electrolyte and gold electrodes deposited on a cellulose diacetate substrate.

The biodegradability is said to have been accredited by the International Standard ISO 14855 and ISEGA, the Research and Investigation Society, Germany. According to the team, the display degrades to an extent of 79.1% after nine weeks, while the reference material only degraded to about 70%.

‘We subjected the display to an independently-conducted biodegradability test according to the international standard ISO 14855 performed in a compost milieu at 25°C…This international standard is the closest to industrial relevant biodegradation methods for solid waste,’ the study reads.

The biodegradation is calculated by giving a ratio between the theoretically expected and the cumulated net-CO₂ production. ‘The CO₂ produced by microorganisms metabolising the organic material is measured over time. Additionally, bioreactors with sole inoculum serve to determine the CO₂ production baseline originating from the compost itself,’ the study continues.

It reports that 20% of the display that has not degraded can be attributed to various materials. A gelatine-based electrolyte has been chosen for its hydrogel configurations and ionic transportation.

‘As an electrochromic layer, we utilised PEDOT:PSS – a material known for its electrochromic properties and outstanding biocompatibility. Complementary, the calcium substrate and gold electrodes are established biodegradable and inert materials, respectively,’ Pietsch notes.

He adds that the display contains 32 individual addressable segments to display time, weather information, battery status and Wi-Fi. ‘Additionally, you have the freedom of design optimised for any special application due to the inkjet-fabrication process. The functionality and performance of the display is comparable to similar electrochromic devices in literature.’

The electrochromic effect results in a change in colour used to display information. The team reports that such displays observe a reversible change between a transparent and a deep blue state with high contrast and fast switching time of 3.0 ± 1.4s.

The researchers aim to enhance device performance by optimising the electrodes and increasing the colour gamut by adding other biodegradable electrochromic materials. Pietsch states, ‘We want to improve the display by adding multiple colours, extending its lifetime under continuous operation and integrating sensors directly to the display.’