Anglo unveils prototype hydrogen-powered mine haul truck

Anglo American has unveiled a prototype of what it describes as the world’s largest hydrogen-powered mine haul truck designed to operate in everyday mining conditions.

The pilot for the nuGenTM Zero Emission Haulage Solution is a hydrogen-powered ultra-class mine haul truck. It’s an ambitious project that marks the first time a truck of this size and load capacity (a 220t truck with a load capacity of 290t = a total laden weight of 510t) has been converted to run on hydrogen that will be produced on-site in hybrid combination with a battery

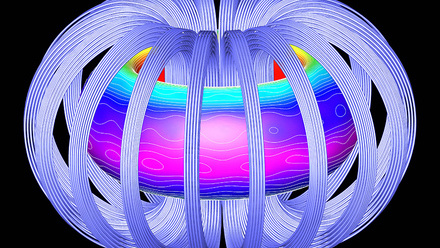

© Anglo American PlcThe 2MW hydrogen-battery hybrid truck, generating more power than its diesel predecessor and capable of carrying a 290t payload, is part of Anglo American’s nuGen Zero Emission Haulage Solution (ZEHS). It provides a fully integrated green hydrogen system, consisting of production, fuelling and haulage system, with green hydrogen to be produced at the mine site.

Duncan Wanblad, Chief Executive of Anglo American, says ‘[This]is] changing the future of our industry. With diesel emissions from our haul truck fleet accounting for 10-15% of our total Scope 1 emissions, this is an important step on our pathway to carbon neutral operations by 2040. The mining industry is playing a considerable role in helping the world decarbonise, both through our own emissions footprint and the metals and minerals that we produce that are critical to low carbon energy and transport systems.’

Developing the prototype involved –

- Designing, building, and testing a 1.2MWh battery pack, as the haul truck system uses multiple fuel cells that deliver up to 800kW of power, combining to deliver a total of 2MW of power.

- Designing and implementing a software solution to safely manage power and energy between the fuel cells, batteries, and vehicle drivetrain.

- Develop the power management and battery systems from the ground up, enabling tailoring the system to each mine and improve overall efficiency by designing in energy recovery as the haul trucks travel downhill through regenerative braking.

- Building a hydrogen production, storage, and refuelling complex at Mogalakwena that incorporates the largest electrolyser in Africa and a solar plant to support the operation of the haul truck.

Hydrogen Valley

In South Africa, the Department of Science and Innovation (DSI) and the South African National Development Institute (SANEDI), in partnership with Anglo American, Bambili Energy, and ENGIE, are looking into opportunities to create a Hydrogen Valley. The proposed hydrogen valley will stretch approximately 835km from the platinum group metals-rich Bushveld geological area in Limpopo province, along the industrial and commercial corridor to Johannesburg and to the south coast at Durban.