An alkaline hydrogel could heal wounds

A hydrogel with potential healing properties is being made in minutes without specialised equipment and at room temperature. Idha Valeur speaks to the creators.

Calcium carbonate, potassium alginate and carbonated water are the three ingredients in a recipe for an alkaline, wound-healing hydrogel produced by scientists in Japan. Up until recently, it had been widely agreed that slightly acidic conditions are preferable to aid wound healing, but recent research reveals that this is not necessarily the case, explains the team from Tokyo University of Science and the Faculty of Science.

They claim to have created the hydrogel in five minutes without any specialised equipment. The polymer alginate, which is derived from brown algae, reacts with the calcium ions in gelation, while the hemostatic effect of the calcium ions is felt on the wound sites. ‘In this method, the pH of the gel shifts to alkaline because the carbon dioxide volatilises after gelation,’ explains Ryota Teshima, Undergraduate Student at the University.

He continues, ‘The pH of the gel has important effects on wound healing, but it has not been [previously] investigated in detail. Many dressings for wound treatment [offer] acidic conditions. For more than 30 years, in clinical practice, it was believed that a pH of four to six, that is similar to that of normal skin, is favourable for wound healing.

‘Indeed, acidic conditions have been shown to exert anti-bacterial properties in wound sites. However, recent reports indicate that alkaline conditions are more suitable for cell proliferation and viability such as fibroblasts and keratinocytes and reducing interleukin-1a (IL-1a) expression. It has also been clarified that an alkaline environment of pH >7.4 is required for skin transplantation. Based on these facts, hydrogels that can provide various pH environments are necessary for wound treatment.’

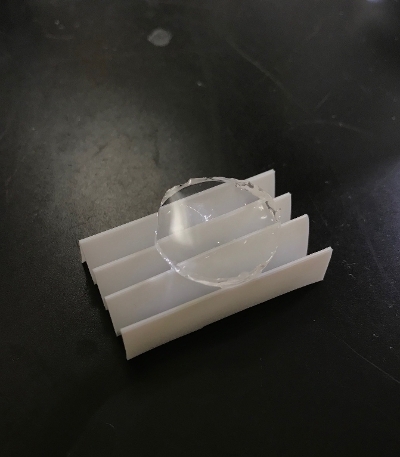

He adds that the new gel has overcome the issue of alginate hydrogels being less transparent while also achieving a short gelation time. As hydrogels can be difficult to store over longer periods of time, Teshima suggests that they should be prepared in situ. He explains that a system is in place in Japan where pharmacists can prepare their own formulations in hospitals, but that requires the gels to be easily manufactured.

‘All of the prepared hydrogels exhibited sufficient transparency for observing the wound site. Moreover, as the calcium carbonate concentration increased, the gelation time decreased, and all hydrogels were prepared within a short time (≤5 minutes), which implies that they can be prepared immediately before use under medical settings. These hydrogels absorb physiological saline. Therefore, these are expected to absorb and maintain exudates at the wound site during in vivo application,’ notes Teshima.

He says that it is the carbonated water instead of an acidic solution that delivers the transparency trick. ‘In fact, calcium carbonate is thought to have been dissolved by carbon dioxide in carbonated water. If this calcium carbonate remains undissolved in the gel, the gel becomes cloudy. We believe that we were able to ensure transparency because the carbonated water contained enough carbon dioxide to react with calcium carbonate.’

The team foresees that if the release time can be controlled and drugs can be stored in the gel, it can also function as a drug delivery system. Teshima states that the research is in the early stages and that the next steps include in vivo trials.