Aerogel sensor uses AI to enhance formaldehyde detection

An aerogel sensor uses artificial intelligence to detect formaldehyde at concentrations of 8ppb using little energy.

The device, developed at the University of Cambridge, UK, reportedly displays sensitivity beyond that of conventional indoor air quality sensors.

The sensors are made by precisely engineering the shape of holes in aerogels to detect formaldehyde at room temperature – pre-existing technology requires heating. The researchers have incorporated machine learning algorithms into the sensors to detect the ‘fingerprint’ of different gases to isolate formaldehyde.

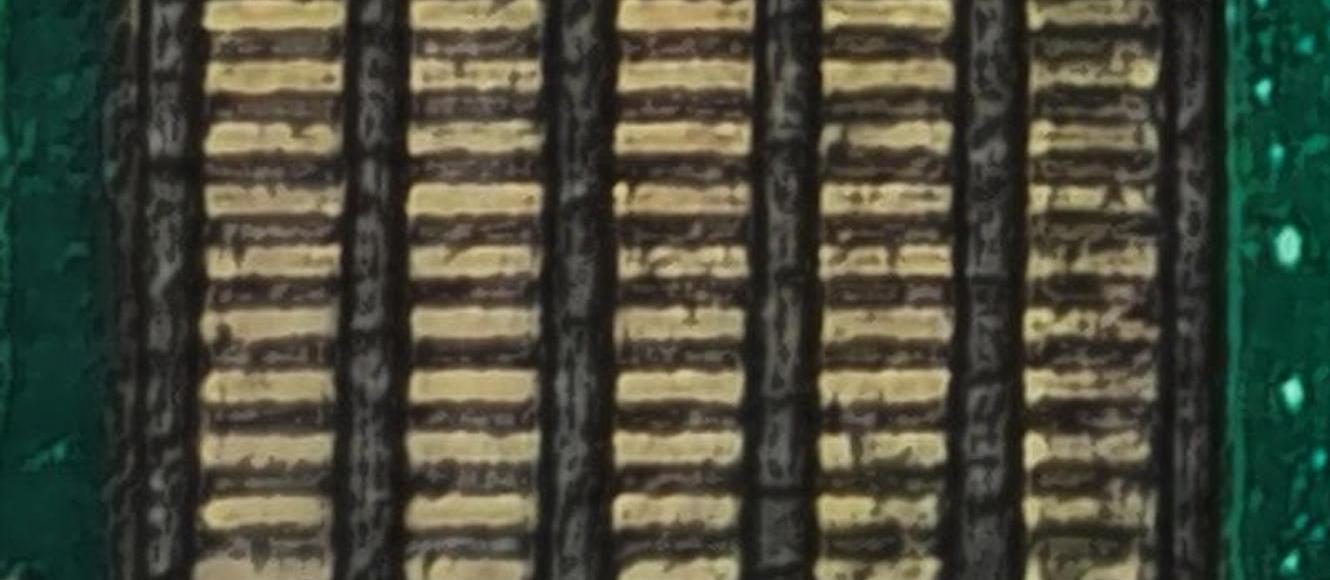

The sensor is fabricated by extrusion-based 3D printing of reduced graphene oxide/quantom dot ((rGO)/QDs) hybrid inks.

Researchers Zhuo Chen (first author) and Tawfique Hasan explain, 'The hybrid materials are first synthesised by a surfactant-assisted hydrothermal growth process, which results in tin oxide (SnO2) QDs uniformly distributed onto the GO sheets…The hybrid and formulated inks are then extruded through a nozzle on a moving stage and freeze-dried to fabricate aerogel filaments of engineered size and surface porosity.

'Additionally, different metal doping of the QDs can be achieved through a liquid-phase ligand exchange strategy by immersing the freeze-dried aerogels in a metal salt solution (CuCl2, NiCl2, CoCl2) in ethanol and then washing with hexane.'

They continue, 'Higher surface porosity favouring gas diffusion can be achieved by choosing an appropriate extrusion speed for a given nozzle size with crosslinked inks having an appropriate rheology.' This promotes faster sensing with enhanced sensitivity.

The hexane washing step removes residual organic ligands and crosslinking agents created after fabrication, exposing the QDs’ surfaces to gas molecules and making it more sensitive.

A subsequent annealing step oxidises the ligand-exchanged metal ions to metal oxide without affecting the aerogel structure.

The team says, 'The formed p-type [copper oxide] CuO dopant on n-type SnO2 QDs contributes to higher sensitivity to formaldehyde through the catalytic effect of CuO and larger resistance modulation of the p-n junction.'

They add, 'The aerogels are fabricated in ultrathin filament form [three times the width of a human hair] instead of thin films to allow for highly efficient gas diffusion.'

Reducing the filament diameter, while ensuring stable and smooth printing, can achieve a higher gas concentration inside the aerogel. 'Combined with optimised surface porosity, this leads to a superior change in their electrical resistance upon gas exposure.'

The detection range is attributed to the high sensitivity of aerogel-filament-based sensors and the high signal-to-noise ratio. 'Our optimised porous structures of aerogel filaments favour fast gas diffusion, while the QDs decorated on the aerogel surface enable highly sensitive response to target gas molecules.

'The chemical signals from gas molecules are transduced to electrical signals and then transmitted by the highly conducting rGO aerogel skeleton with minimum electrical noise. We further enhance the noise resilience of the sensor by designing dynamic-feature-based algorithms that effectively filter out background electrical noise.'

The World Health Organization has set an indoor air quality guideline of 0.1mg/m3 (0.08ppm) for formaldehyde for both short- and long-term exposures, applicable to each 30-minute period during each day over a lifetime.

So, 'ensuring a detection limit at the parts per billion level is essential', say Chen and Hasan. 'More importantly, real-time recognition of formaldehyde from the interference gases is critical for reliable monitoring in complex environments. This constitutes the other highlight of our work, which achieves real-time, noise, and baseline drift resilient recognition of formaldehyde, enabled by dynamic-feature-based intelligent algorithms.' It is reportedly possible to trace formaldehyde’s source and trigger an alarm if concentrations exceed safety limits.

The minimal power required means they can be powered by batteries or indoor lights and installed on demand. The team is now expanding the materials used and developing algorithms to monitor more volatile organic compounds in complex environments accurately.