A spotlight on self-healing flexible electronics

A stretchable material that can repair itself also illuminates visibly at low voltages. Shardell Joseph finds out how.

A flexible material that holds potential for the next generation of electronic wearables and soft robots is the focus of research at the National University of Singapore (NUS). The durable, low-power, rubber-like material is said to have high visible brightness and resilience to damage due to its self-healing properties.

‘We tested the illuminance, or the amount of light emitted per unit area of the device, under different tensile strengths up to 1,000% – 10 times the original strength,’ says Benjamin Tee, Assistant Professor at NUS. ‘The outcome was that the light emitted actually increased when strained up to about 400%. The device continued to emit light when it started to tear at about 800%, which is quite remarkable.’

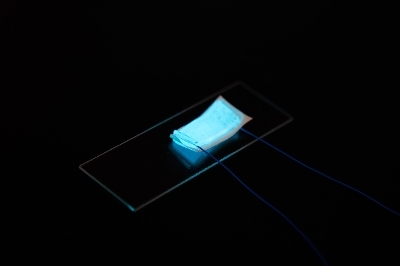

The HELIOS material – healable, low-field illuminating optoelectronic stretchable – is a transparent, electric rubber sheet made up of fluoroelastomer and surfactant, created by dispersing light emitting particles in a synthetic polymer mixture.

‘The material works by making use of a stiff polymer and turning it soft through ionic-dipole interactions,’ Tee explains. ‘We basically “plasticise” the original stiff polymer and turn it stretchable through our process. These ionic-dipole bonds are weak, but with enough of them, they can interact sufficiently to give them the ability to stretch.’

According to Tee, it is the ionic-dipoles that allows the mechanically flexible material to heal, as the bonding can re-attach itself easily at room temperature. ‘We fill the material with a lot of these bonds, making it strong enough that it makes the material rubbery, and yet because the bonds can re-attach easily, it can heal autonomously,’ says Tee.

If a cut is applied to the material, the bonds will quickly find other neighbouring bonds to attach, similarly to automatic nano-zippers – they can automatically zip up by finding neighbouring bonds.

Because the material is highly transparent, much more light can be emitted when powered. It also has high dielectric permittivity – significantly higher than most silicones or rubber material – allowing it to store more electronic charges at lower voltages and enables a higher brightness when used in a light-emitting capacitor device. The material can therefore light up when the voltage alternates.

Tee explains that the invention could be useful in illuminated textiles for safety or emergency purposes such as disaster zones. ‘Newer forms of soft robots that can be used in urban farming can use such materials to illuminate and tell whether a fruit is ripe, even in the dark, and harvest it at the right time,’ he adds.

Because the material is soft and stretchable, it can conform and be applied to curved surfaces such as foldable phones. It is also suitable for wearables as it can be applied to clothes easily without fear of breakage.

The team claims the material can be scaled up for manufacturing. ‘We are able to make the material printable, and hence it can be manufactured using existing production lines that do screen printing,’ says Tee. ‘The raw materials that we are using are also available and do not need special synthesis.’