A carbon boost for computers

Transistors fabricated entirely from carbon wires could increase our computers’ processing speeds and reduce their power consumption.

‘It is the first time that we can intentionally create an ultra-narrow metallic conductor – a good, intrinsic conductor – out of carbon-based materials, without the need for external doping,’ says Felix Fischer, Professor of Chemistry at the University. ‘That has been one of the key things that has been missing in the big picture of an all-carbon-based integrated circuit architecture.’

Similar to traditional silicon-based architectures, current carbon-based transistor technology still requires some form of metallic interconnects that allow for communication between individual transistors or other circuit components. Fischer explains that manufacturing these architectures becomes easier if you can make the metal wire and the transistor out of the same material, i.e. carbon.

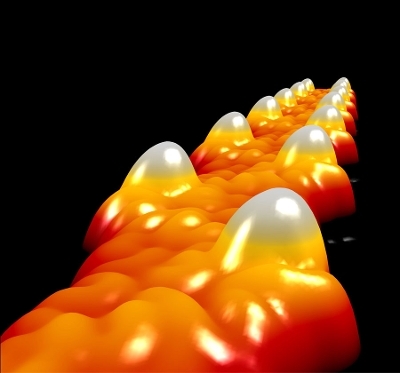

The new wire – based on a graphene nanoribbon (GNR) – is intended to conduct electrons between semiconducting nanoribbons in all-carbon transistors.

‘The technology we are developing in collaboration with our partners in the Departments of Electrical Engineering and Computer Science and the Departments of Physics at UC Berkeley is based on new architectures that have the potential to reduce the power consumption of integrated circuits by a factor of 103 while increasing the speed of computations by a factor of 104 to 105,’ Fischer notes.

‘Rather than relying on thermionic emission where electrons have to jump over a semiconducting barrier to get from the source to the drain electrode, we use a principle where the electrons can just tunnel through the barrier if the conditions are just right.’

Michael Crommie, a UC Berkeley Professor of Physics, explains how the metallic nanoribbons are built by assembling them from smaller identical building blocks, labelled as a bottom-up approach. Each building block contributes an electron that can flow freely along the nanoribbon.

‘Nanoribbons allow us to chemically access a wide range of structures using bottom-up fabrication, something not yet possible with nanotubes,’ Crommie says. ‘This has allowed us to basically stitch electrons together to create a metallic nanoribbon, something not done before.’

The team believes that if they are successful in demonstrating that the carbon-based GNRs can outperform current advanced silicon-based semiconductor technologies in the next 10-15 years, then there could be an incentive to integrate them into everyday devices.

‘Think about the possible impact of a mobile phone with comparable performance to the fastest desktop computers but with a power consumption that requires you only to charge it every other month,’ says Fischer. ‘There are still a handful of grand challenges along the way to see the realisation of this vision, but with this paper we made a huge step forward in that direction.’

Fischer states that in the shorter term, the next two-to-three years, the team is expecting to see the materials integrated into biomedical and environmental sensors. ‘The translation of this technology into an integrated circuit is still a steep and [winding] road ahead, but we are confident that following a proof-of-concept that validates the predicted performance, the field will attract many more expert research groups and an increased federal and industrial backing to support this effort.’