Alan Glanvill Award

The Alan Glanvill Award is presented annually for published work of particular merit in the field of polymers.

Eligible papers must have been published 2 years before the award is presented in a relevant IOM3 Journal, such as:

- Interdisciplinary Science Reviews

- International Materials Reviews

- Materials Science & Technology

- Plastics, Rubber & Composites: Macromolecular Engineering

The winner will receive a certificate and £450.00

Award judges

Past winners

2024

Effect of Zn-nanoHA concentration on the mechanical performance and bioactivity of 3D printed PEEK composties for craniofacial implants

Dr Faisal Manzoor, Dr Atefeh Golbanga, Prof Alistair Mcllhaggera, Prof Eileen Harkin-Jonesa, Dr Daniel Crawford, Elena Mancuso

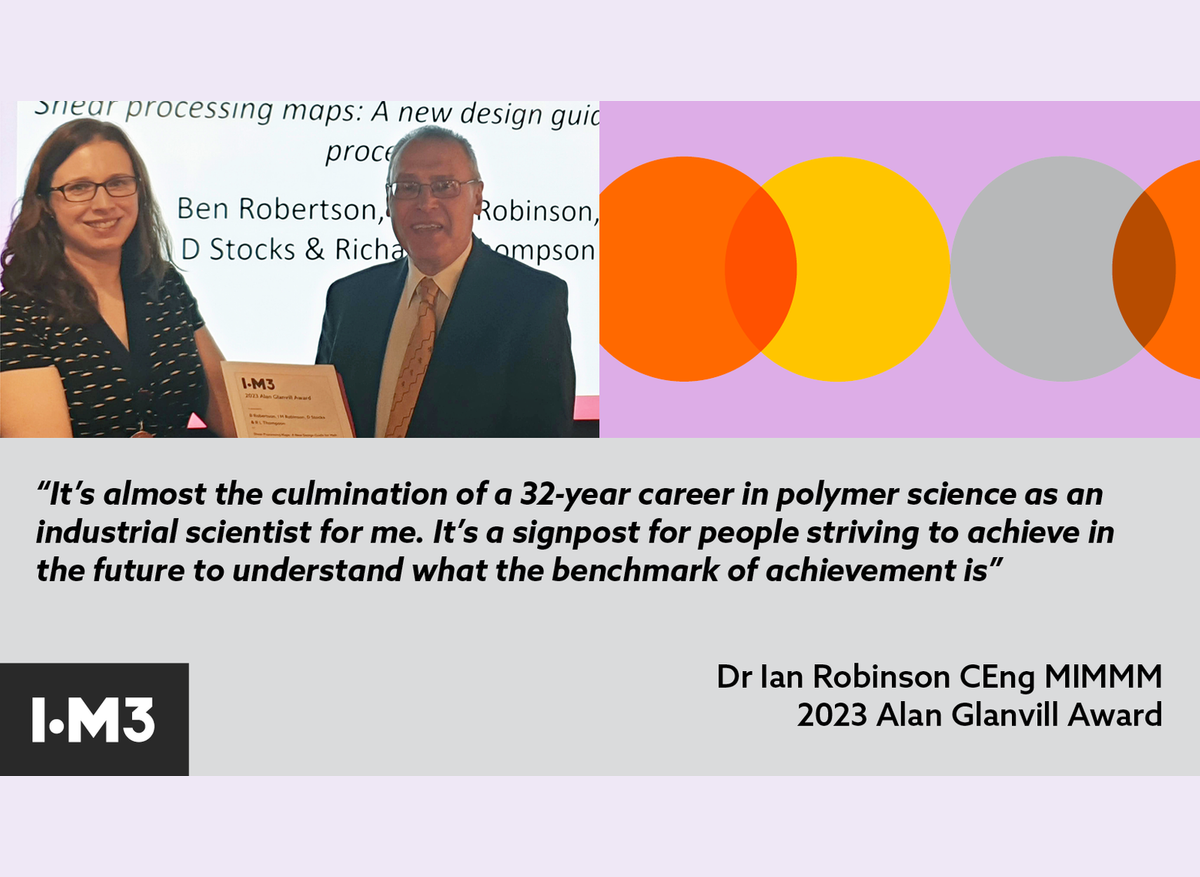

2023

Shear Processing Maps: A New Design Guide for Melt Processors

Ben Robertson, Ian M Robinson, D Stocks, & Richard L Thompson

2022

Flexible piezoresistive strain sensor with high sensitivity based on carbonised waste thermosetting resin

Lei Wang, Dong Xiang, Wanqiu Zhu, Chunxia Zhao, Yuntao Li, Hongchang Han, Ping Wang & Jie Wang

2021

Not awarded

2019

Highly stretchable and sensitive strain sensors using nano-graphene coated natural rubber

S Tadakaluru, T Kumpika, E Kantarak, W Sroila, A Panthawan, P Sanmuangmoon, W Thongsuwan & P Singjai

2018

Evaluation of commercial Mg(OH)2, Al(OH)3 and TiO2 as antimicrobial additives in thermoplastic elastomers

M Pittol, D Tomacheski, D N Simões, V Ferreira, R R Marlene & C Santana

2017

Three-dimensional finite element method simulation study of fusion screw geometry

P. Kubik, M. Zatloukal, J. Vlcek & T. Womer

2016

Effect of processing temperature on structure and properties of microinjection moulded thermoplastic polyurethane/multiwalled carbon nanotube composites

D. Li, T. Zhai, Q. Gong, G. Fei & H. Xia

2015

Pyrolytic carbon: factors controlling in-rubber performance

C. J. Norris, M. Hale & M. Bennett

2014

Properties, morphology and structure of BPDA/PPD/ODA polyimide fibres

S B Huang, Z Y Jiang, Y Ma, X P Qiu, Y F Men, L X Gao & M X Ding

2013

Characterisation and analysis of microchannels and submicrometre surface roughness of injection moulded microfluidic systems using optical metrology

G Tosello, F Marinello & H N Hansen

2012

Preparation, structure, performance, industrialisation and application of advanced rubber / clay nano-composites based on latex compounding method

Dr L.Q. Zhang et al

2011

Evaluation of replication properties on moulded surface by ultrasonic injection moulding system

A Sato, H Sakaguchi, H Ito & K Koyama

2009

Macro- and microdispersion of carbon black in liquid silicone rubbers

H Le, S Ilisch, H Radusch & H Steinberger

2008

New technology for thermal processing of poly (vinyl alcohol)

N Chen (Sichuan University), L Li & Q Wang

2007

Industrial applications of gas assisted injection moulding: numerical prediction and experimental trials

A Polynkin, J F T Pittman & J Sienz

2006

Microstructure and kinematic aspects of blown film extrusion process: II. Numerical modelling and prediction of LLDPE and LDPE

L K Hendrichsen, A J McHugh, S S Cherukupalli & A A Ogale

2005

Mesoscale modelling of processing rubber-toughened acrylic polymers

Dr K Porfyrakis & Dr H E Assender

2004

Effect of process variables on melt velocity profiles in extrusion process using single screw plastics extruder

R Rasid & A K Wood