Up to standard - fire safety testing

Juliane Fitz at NETZSCH explains how materials are passed fit for fire safety.

Given the potential risk to life, preventive fire protection is always important.

If materials are designed in such a way that they do not burn or are very difficult to ignite, disastrous fires can be effectively prevented. Preventive fire protection therefore begins with the selection of suitable raw materials and goes on to the production, testing and constant optimisation of individual materials and products, from that of building materials to the interior design of vehicles and airplanes, various textiles, and cables and conductors.

It is not only the manufacturer of individual materials that are interested in testing the quality and burning characteristics of their own products, numerous testing and certification institutes, as well as colleges and universities, are interested in fire testing devices for test and teaching purposes.

The most important burning characteristic in nearly all fire tests is the flammability of the tested material or components in general. Fire tests aim to identify how long it takes until a material ignites under defined conditions. The flame spread and smoke development as a function of time, as well as the amount of heat released during the burning process, are monitored.

The primary aim is to determine how much time is left before the fire spreads. This is of particular importance to save lives. In addition, enormous amounts of smoke in the event of a fire can severely impair extinguishing and rescue work and also cause smoke poisoning.

In class

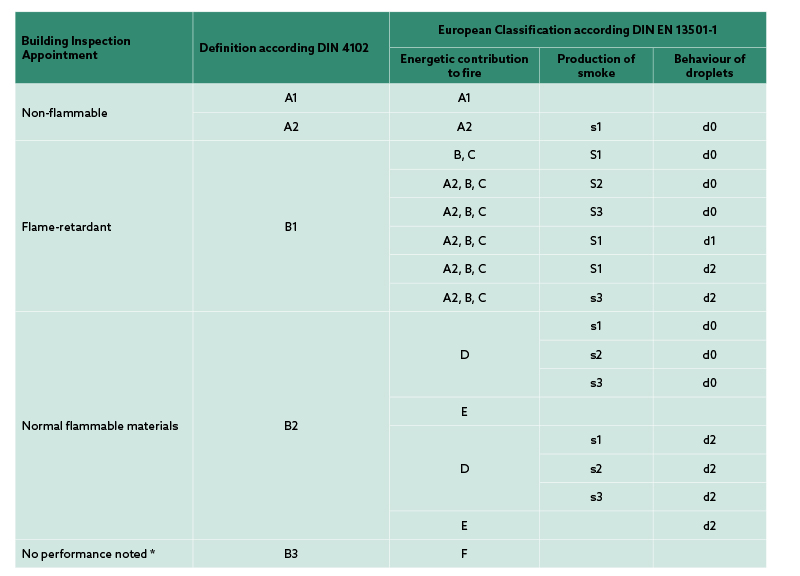

All these characteristics ultimately lead to the classification of successfully tested products – the so-called Euro Classes according to DIN EN 13501-1/-5 (see table opposite).

The classification of a product indicates how flame-retardant the material is and, at the same time, how much smoke, heat and burning droplets are generated in the event that it does ignite.

Fire test regulations require new and constantly improving quality standards, contributing to a safer world with the use of appropriate test equipment.

Building a picture

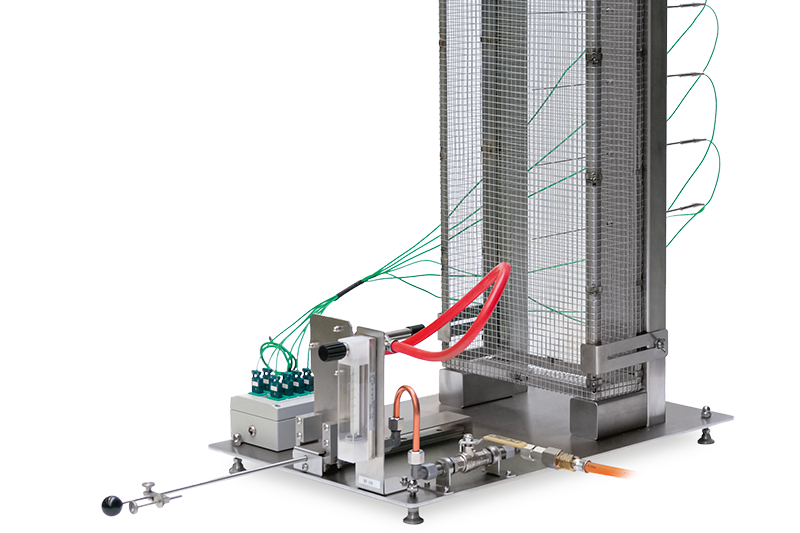

When testing cables, it is important to measure the heat release and smoke production during flame spread tests on vertically mounted bunched cables and insulated wires, in accordance with standards EN 50399 and IEC 60332-3-10.

The reaction of building products to fire when exposed to thermal attack by a single burning item is carried out in accordance with EN 13823. Here, end-use typical wall structures are arranged as test specimens at a right angle, and a room fire starting in a corner is simulated. In this test, examination of the combustion gases plays a major role in classifying the product.

An extra classification is required for floor coverings. Here, we can simulate the probable degree of stress that is exerted on a floor in a corridor using the thermal radiation imposed on the sample by the radiator. Flames and/or hot gases are assumed to be present in the early phase of fire development in an adjacent room or section. The results of this test are particularly relevant for the use of floor coverings in public buildings, such as hotels.

There is also a corresponding fire testing device for fundamentally non-combustible material, identifying which building products contribute very little, if anything, to a fire’s progression.

Based on these results, the appropriate building product for a structure is selected. Testing of non-combustibility serves for classification into the European fire classes A1 and A2.

Heat release

Analysis of the heat release rate and the dynamic smoke production of a product is essential in fire testing, and is based on the principle that the amount of heat released by the burning sample is directly related to the amount of oxygen consumed during forced combustion.

The amount of heat produced by a material is therefore directly related to the severity of a fire, expressed, for example, by its rate of spread. The ability to monitor the development of a fire from a very early stage means we can predict fire behaviour on a real scale, enabling safe evacuation of buildings, airplanes, cars and boats in case of emergency.

The integrated SIEMENS gas analysis forms a symbiosis with the NETZSCH devices and enables a precise examination of the combustion gases. In large fire testing systems, not

only is the composition of the combustion gases considered, but it is important to know the smoke density. Measuring the transmission by means of a white light measuring section or a laser light measuring section serves to establish those values.

A selection of smaller benchtop fire testers are mostly used to pre-test materials such as building materials and vehicle interiors for their flammability.

End-user

In addition to the safety of the material to be tested, the safety of the user and ease of use are the main priorities in device development. In-house, integrated software solutions that move with the times make operating the fire testing devices a real experience in addition to the test itself.

Preventing fires entirely will probably remain an unattainable goal, but designing and using materials as safe and flame-resistant as possible to gain time to save lives and substance is becoming within reach with preventive fire testing.