Ultra-light material energises solar potential

A non-toxic printed ink can absorb more sunlight than a silicon solar cell.

The non-toxic nanomaterial made from sodium bismuth sulphide (NaBiS2) can absorb sunlight far more strongly than conventional silicon solar cells, but is 10,000 times thinner, claims the joint UK-German collaboration behind its production.

Printed from an ink, the material could offer an alternative, lightweight source of photovoltaic solar panels, easing transportation to remote locations and providing novel aerospace applications.

Led by Imperial College London, with input from Cambridge University, Oxford University and University College London (UCL) in the UK, alongside Helmholtz-Zentrum in Germany, the scientists were inspired by research into silver bismuth sulphide (AgBiS2) cells.

Silver and bismuth share the same crystallographic site, leading to the cation disorder effect. Sodium has the added benefit of being cheaper and less toxic than silver.

Dr Robert Hoye, at Imperial College London, explains how AgBiS2 demonstrates excellent light-harvesting abilities and uses ultra-thin layers. 'By controlling the level of cation disorder, very high absorption strengths can be achieved. But, at the same time, the strength of absorption slowly increases from the absorption onset, namely the bandgap. We wanted to explore more broadly cation-disordered materials, and whether we can achieve materials with stronger absorption onsets.'

Seán Kavanagh, co-first author and PhD student in research groups at Imperial and UCL, comments, 'Disorder has long been seen as the enemy of solar cells…Rather if we can understand and control this disorder, it can present a powerful tool to tune material properties.'

To produce the material, chemicals with Na, Bi and S are dissolved in an organic solvent (oleyamine) and then heated, creating small nanoparticles in a crystallised form. By varying temperatures, nanoparticle sizes can be tuned, from 5-20nm.

'We then need to purify these NaBiS₂ nanoparticles out of the solution by adding some polar solvents...and centrifuge the mixed solution to precipitate these nanoparticles,' explains Yi-Teng Huang at the University of Cambridge.

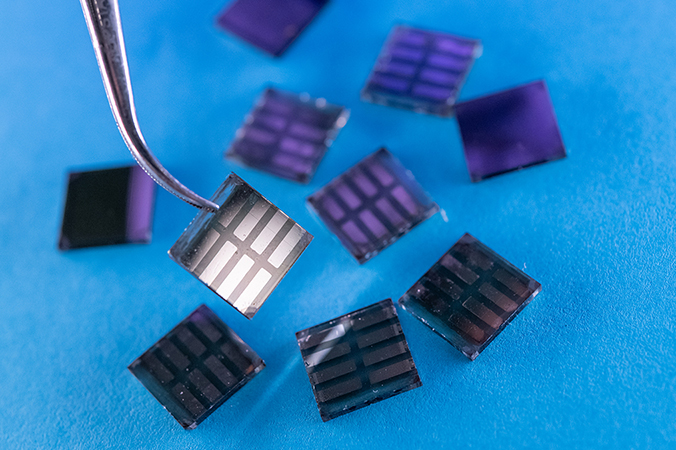

The purified nanoparticles are then redissolved in a hexane solution, which can be dropped or spun onto a glass or another substrate to produce NaBiS2 films. X-ray diffraction patterns confirm the material’s crystal spacing and structure.

Huang says the team uses a spectrometer to evaluate the films’ absorption strength and bandgap. The absorbed light, from ultra-violet to near-infrared region, can also be calculated.

Ultrafast spectroscopic measurements are then performed to better understand what happens when the films absorb light. The disorder has a significant and unusual effect on the transport of photogenerated charges in the material.

'These techniques shine an excitation light pulse into our material and monitor the excited carrier populations with another weak light pulse arriving [after] the first one,' Huang continues.

'Since NaBiS₂ can strongly absorb the excitation light pulse, many charge carriers will be generated after that, leading to a change in transmission rates or conductivity. The weak [second] light pulse won’t further change these features but can be used as an indicator for carrier population when comparing with the features before excitation.'

The material’s ultra-strong optical absorption is ideal for use in ultra-thin solar cells, note the researchers. They believe it is plausible to manufacture solar cells tens of nanometres thick.

The next step is to better understand the limitations identified in the material’s power-conversion efficiency.

'Defects in the material produce electron traps, which prevent electrons from escaping as electricity...Improving our understanding of this trapping behaviour and the chemical properties that this favour will allow us to engineer further improved ultra-thin solar cells...potentially even overtaking silicon as the dominant solar cell technology.' says Kavanagh.

The NaBiS2 material was found to be stable in air for the span of the 11-month test without any encapsulation required.