UK’s first centre for rare-earth magnet recycling

Rare-earth magnets will be recycled for the first time in the UK at a plant at Birmingham’s Tyseley Energy Park.

The Tyseley plant is being developed with the University of Birmingham and is expected to have a minimum production capacity of 100t a year. This is a £4.3mln project.

HyProMag’s core technology is based upon the patented process – Hydrogen Processing of Magnet Scrap (HPMS), which was originally developed within the University’s Magnetic Materials Group (MMG) to extract rare earth magnets from scrap and redundant equipment and subsequently licensed to HyProMag.

HPMS is used to reduce permanent magnets containing neodymium iron and boron to a demagnetised powder.

Rare earth recycling company HyProMag, which was formed by researchers from the University of Birmingham’s School of Metallurgy and Materials, is to be acquired by Maginito Ltd, in a deal that aims to aid the further scale-up and international roll-out of technology first piloted at the University of Birmingham.

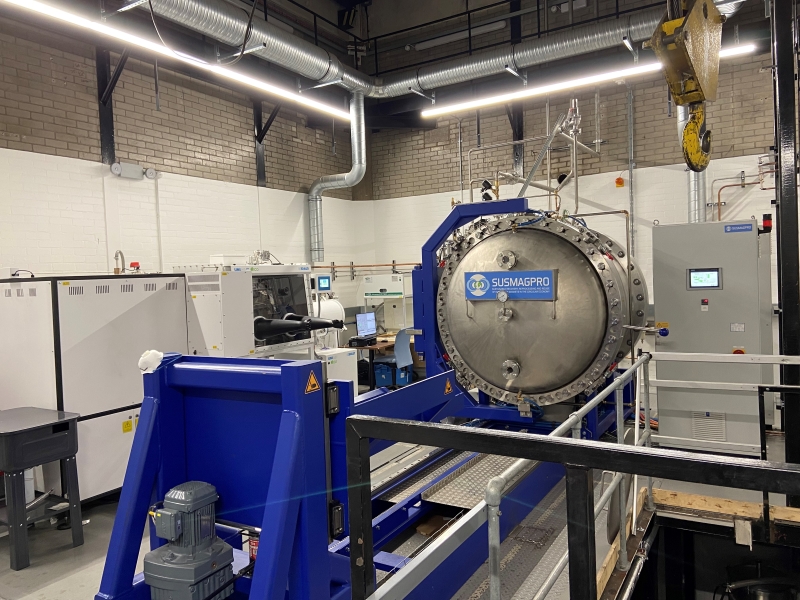

A pilot plant for HPMS recycling opened at the University of Birmingham last year, and work is now underway to build a large scale ‘short loop’ recycling facility at Tyseley and other locations. First production is expected in the UK in 2023 and in Germany in 2024.

Short loop magnet recycling is expected to require an estimated 88% less energy versus primary mining to produce a sintered magnet.

Mkango has partnered with HyProMag since its inception in 2018.

A new US subsidiary, jointly owned by Maginito and CoTec, is expected to be formed to develop rare earth recycling opportunities in the United States.

Recycling rates for these magnets are currently very low (less than 5%).