Tailored timber grown in a lab

Scientists at the Massachusetts Institute of Technology, USA, say they can control the properties of a wood-like plant material that is grown in a laboratory.

The team has found that by adjusting certain chemicals during growth, they can control physical and mechanical properties, such as stiffness and density.

Senior author Luis Fernando Velásquez-García says, ‘This research demonstrates that lab-grown plant materials can be customised to have specific characteristics, and researchers could eventually grow wood products with the features required – such as high strength or certain thermal properties for example.’

3D bioprinting also allows the team to ‘grow’ the plant material in shapes, sizes and forms not found in nature or easily produced with traditional agricultural methods.

Research lead, Ashley Beckwith, adds, ‘The idea is that you can grow these plant materials in exactly the shape that you need, so you don’t need to do any subtractive manufacturing after the fact, which reduces the amount of energy and waste.’

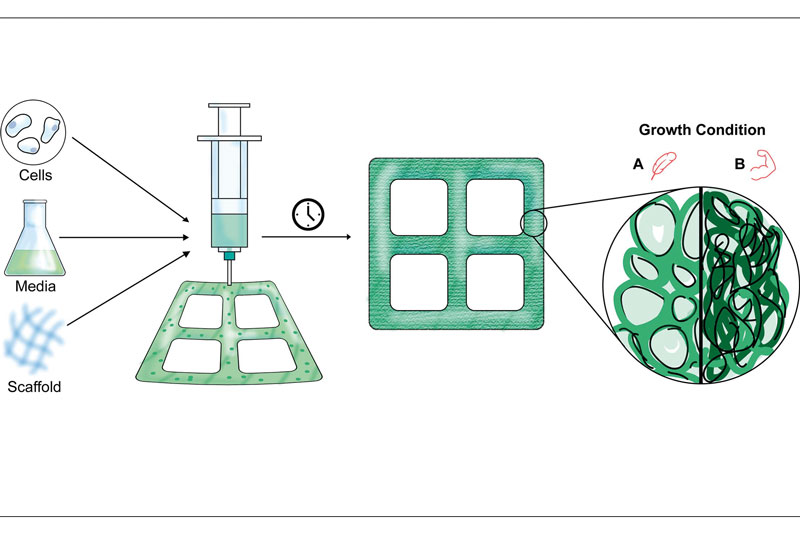

To achieve this, the researchers first isolate cells from the leaves of young Zinnia elegans plants. They culture the cells in a liquid medium for two days before transferring to a gel-based medium, with Xenon as a base, with nutrients and two different hormones, specifically, alpha-naphthaleneacetic acid and benzylaminopurine.

Adjusting the hormone levels at this stage enables tuning of the cells’ physical and mechanical properties as they grow in nutrient-rich broth.

Cultures are maintained in a shaker at 80rpm, and samples taken intermittently.

Velásquez-García says that these growing plant cells behave like stem cells in the sense that researchers can give them cues to tell them what to become.

A 3D printer extrudes the cell culture gel solution into a specific structure in a petri dish that is incubated in the dark for three months. The process, the researchers say, is about two orders of magnitude faster than the time it takes for a tree to reach maturity. The cell-based material is then dehydrated before being evaluated.

Lower hormone levels yield plant materials with more rounded, open cells with lower density, while higher hormone levels lead to a material with smaller, denser cell structures. Increased hormone levels also add stiffness, and the researchers describe producing a plant material with a storage modulus similar to that of natural woods.

Another goal of this work is to study ‘lignification’ in these lab-grown plant materials. Lignin is a polymer that is deposited in the cell walls of plants to make them rigid and woody. The team has found that higher hormone levels in the growth medium enhances lignification, which leads to more wood-like properties.

Furthermore, the cell cultures can survive and grow for months after 3D printing, and using a thicker gel to produce a thicker structure does not impact the survival rate. Initial results published in the paper, Physical, mechanical, and microstructural characterization of novel, 3D-printed, tunable, lab-grown plant materials generated from Zinnia elegans cell cultures, reveals that the cells can survive at more than 8.7mm distance from the gel surface for at least 32 days.

Next steps involve gaining a better understanding and control of cellular development. The team wants to explore how other chemical and genetic factors direct the growth of cells.

The team hopes to transfer their method to a new species as Zinnia plants do not produce wood. If the method was used for a commercially important species such as pine, they say it would need to be tailored to that process.