Skin deep – robotic finger points to biomedical advances

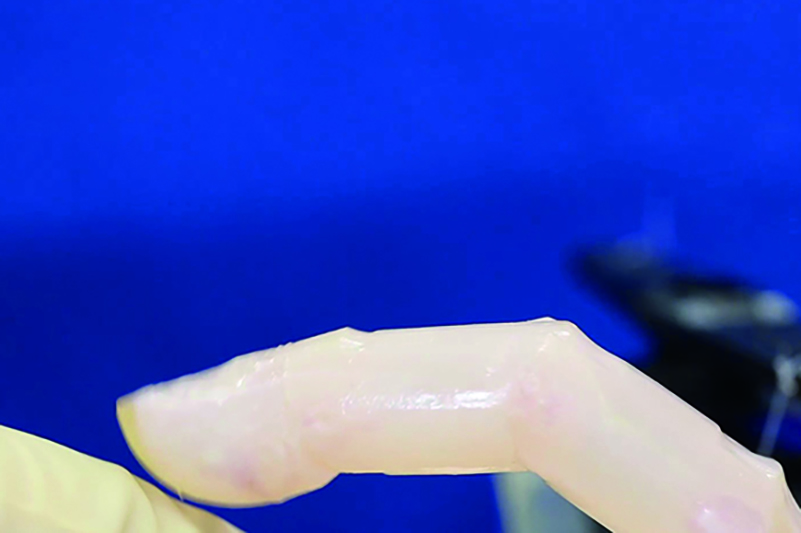

Researchers at the University of Tokyo, Japan, have created a controllable robotic finger coated with living skin tissue.

The aim of the research is to aid medical research on deep wounds and burns, as well as advance manufacturing.

Professor Shoji Takeuchi says, 'We have shown that living skin tissue can be used as a coating material for robots. This result has the potential to make robots look more human-like and have the ability of self-healing.'

The synthetic skin is made from a lightweight collagen matrix known as a hydrogel, within which several kinds of living skin cells called dermal fibroblasts and epidermal keratinocytes are grown.

The skin is grown directly onto the robotic component, requiring specially engineered structures to anchor the collagen matrix.

Takeuchi says, 'The technology is to cultivate skin in accordance with the 3D aspect. We found that we could adapt the skin to the curved 3D surface shape by culturing it on site, rather than making it elsewhere and attaching onto the surface. By installing an appropriate anchor structure, the entire surface could be covered.

'Previous methods of fabricating living skins can only achieve planar-shaped skin sheets. It would be very difficult to use these planar sheets to cover 3D objects with uneven surfaces like the body of robots – you have to have the hands of an artisan who can cut and tailor with skills. We established a tissue moulding method to direct mould skin tissue surrounding the robot, which resulted in seamless skin coverage on a robotic finger with an uneven surface. We are surprised by how well the skin tissue conforms to the robot’s surface.'

He continues, 'Currently, the layer is 1.5mm thick and made only of epidermis and dermis, so it does not look perfectly like skin – there are no sensory neurons, hair follicles, nails, sweat glands and hypodermis, etc. However, as the robot moves, the skin stretches and contracts, revealing wrinkles – my personal impression is that it is much more realistic than silicone.'

The researchers note that there are three benefits of using living cells as a coating material for robots. (1) By using the same skin material as humans, a more human-like appearance can be achieved. (2) The biological properties of cells can be used to provide robot skin with multimodal and multichannel sensing capabilities, self-repair capabilities, and metabolic capabilities that are difficult to achieve with artificial materials alone. (3) By using biological materials, robots can be made more environmentally friendly.

Takeuchi believes that the finger will be useful where in situ repairability is important as well as dexterity and light touch. He says, 'One of the challenges is that there is no circulatory system built within the skin so the skin cannot last long after being taken out from the culture medium. We are conceiving strategies to build circulatory systems within the skin.

'Another challenge is to develop more sophisticated skin with skin-specific functions by reproducing various organs in the skin, such as sensory neurons, hair follicles, nails and sweat glands. Also, scaling up our current method to cover larger structures would also be a challenging next step.'

The long-term goal is to open up new possibilities in advanced manufacturing industries where currently only a human being can operate a control. Other possible fields include cosmetics, pharmaceuticals and regenerative medicine.