Shed microplastics in the wash no more

A team of researchers at the University of Toronto, Canada, have designed a solution to reduce the amount of microplastic fibres shed when washing synthetic fabrics.

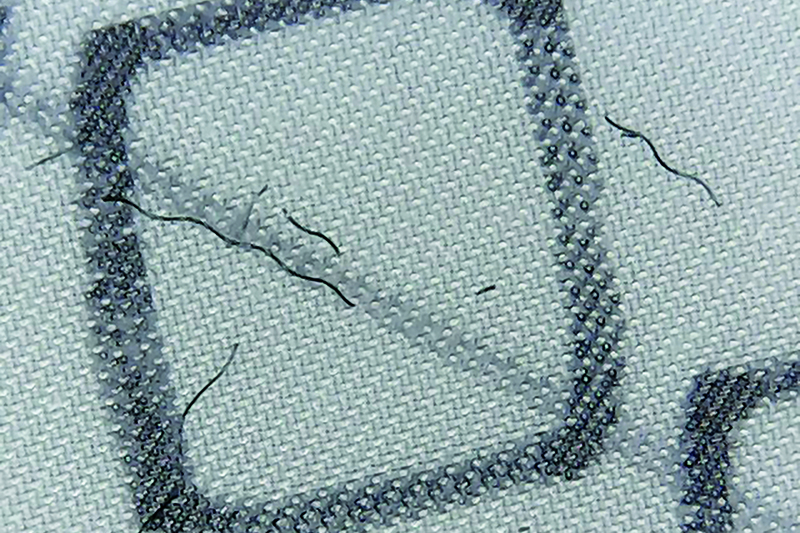

The friction caused by cleaning cycles in the washing machine produces tiny tears that release microplastic fibres – measuring less than 500µm in length – that make their way down laundry drains to enter waterways, where the particles can be difficult to remove and take decades or more to fully break down.

A silicone-based organic polymer coating, found in many household products, could offer a solution.

Professor Kevin Golovin and his team have created a two-layer coating made of polydimethylsiloxane (PDMS) brushes, which are linear, single-polymer-chains grown from a substrate to form a nanoscale surface layer.

Golovin says, 'The silicone coating we have studied for many years in all sorts of industrial applications…And more recently we discovered our silicone has a very low coefficient of friction, so it was the natural choice for the microplastic-preventing application on apparel. The primer was selected to strongly bond to both silicone and nylon, using techniques borrowed from textile dyeing.'

He continues, 'There is likely 10-100 times more silicone than primer on the finished fabric, but that’s an estimate based on our results on flat surfaces like glass. The primer is applied from a solvent solution, similar to how most apparel is finished. The silicone is applied as a gas, where vapours of our precursor molecules condense and react with one another and build the layer onto the textile conformally. However, we are currently working on waterborne formulations for both the primer and silicone layer, as these would be easiest for textile mills to adopt.'

Neither the primer nor the PDMS brushes work separately to decrease microplastic-fibre shedding, but together, they have created a strong finish that is said to reduce the release of microfibres by more than 90% after nine washes.

The team has tested the coating over 10 washes with no loss of performance (40°C water, each for an hour) as well as a ‘harsh’ wash at 60°C for 24 hours, again with no loss in performance. 'So at the moment, the coating appears quite robust and it isn’t clear when reapplication would be necessary,' says Golovin.

The team recognises that silicones are neither biodegradable nor compostable from a chemical standpoint, but they are also environmentally benign and non-toxic to humans. 'Because our coating is so thin (almost molecularly thin), negligible mass remains. And so from an industrial classification standpoint, the coating is both biodegradable and compostable, but again this is more of an issue with how industry classifies these things.'

He says the PDMS doesn’t affect the fabrics’ other properties because it is so thin.

The primer they have developed is specifically for nylon. Golovin says, 'Slightly different primers would need to be designed for other fabrics like cotton, wool, regenerated cellulose, etc. We’ve started on this already.'

This material cannot, however, replace waterproof layers. Golovin adds, 'We are able to get some oil repellency using the PDMS coating, but not as well-performing as perfluoroalkyls (PFAs). There’s still more work to be done in this area for sure.'

Golovin concludes, 'When we look at what governments around the world are doing, there is no trend towards preventing the creation of microplastic fibres in the first place. Our research is pushing in a different direction.'