Self-folding origami honeycombs for protective packaging

A low-cost method to make paper sheets fold themselves into honeycomb structures has potential for tailor-made protective packaging for fragile goods, including electronic components or vegetables, as well as protective gear such as helmets.

Japanese scientists have developed the technique using nothing but paper, a cutter and an inkjet printer, inspired by origami.

Honeycomb structures are widely used in materials engineering with attractive properties, including low weight, high porosity, heat insulation, and excellent mechanical shock absorption.

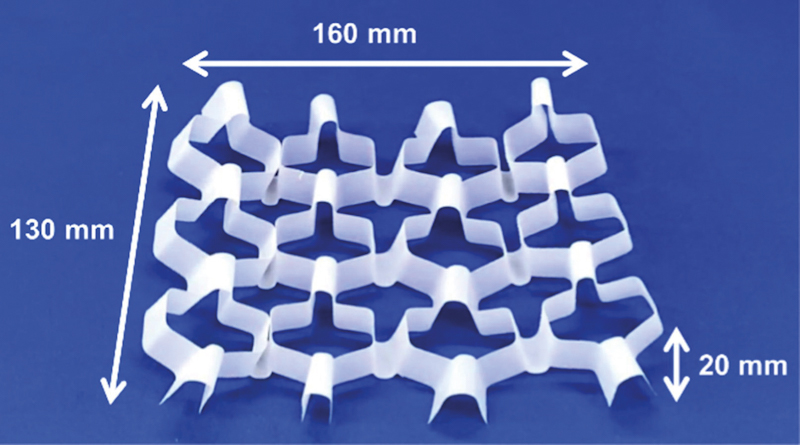

Through this new technique, 'a paper origami honeycomb structure has been developed that can withstand a force of 500N and achieve an energy absorption of 8,249N-mm', says Associate Professor Hiroki Shigemune at the Shibaura Institute of Technology (SIT), Japan.

Shigemune’s team recognised one of the most difficult aspects of using origami in practical applications is finding a convenient, cost-effective way to fold the sheets of material into the desired shape. The process can be particularly challenging for either very small or very large origami structures.

The key to this is to take advantage of the physicochemical interactions between the paper and the printed solution. So, the structure is formed autonomously by a reaction between the printing solution and the paper.

The researchers first cut out a grid of rectangles on a flat paper sheet and then use the inkjet printer to apply the printing solution in a carefully devised pattern. This results in the honeycomb structures folding themselves in a matter of minutes. The paper structure becomes lighter and stronger through the honeycombing process.

The team has analysed how various parameters of the cutting and printing patterns affect the structural and mechanical properties to find a set of optimal parameters. Then they tested additional ways to improve the mechanical performance.

The first was by stacking multiple honeycomb layers on top of each other, which increases the cushioning performance with negligible height changes.

The second involves pre-straining the honeycomb structure, essentially applying a strong compressive force before use to eliminate the compressive force peak that occurs the first time a brand new self-folding origami honeycomb structure is compressed. This is a phenomena that could damage the protected object.

The team notes that an advantage is that the structures are made from paper, a material that requires less storage space and can be processed quickly at low cost.

'The material used is the paper itself, which is cheap. The production equipment is also compact, so the initial cost of introduction becomes low,' says Shigemune.

The researchers propose that it could be considered a ‘green technology’ as they are made from nontoxic materials using very little energy.

Potentially, the tailor-made feature of the system is promising, 'as it allows for the immediate fabrication of an appropriate structure depending on the size and weight of the object,' suggests Shigemune.

He explains that the origami technologies are scalable and can apply to micro and macro scales. Improvements will be made in the future to develop more application-oriented structures.