Scientists bridge the human-machine interface with electronic ‘living’ material

Bridging the gap between machines and the human body, a soft electronic ‘living’ material may facilitate medical diagnostics and treatments in real-time through its inherent controlled release of drugs and sensing capacity.

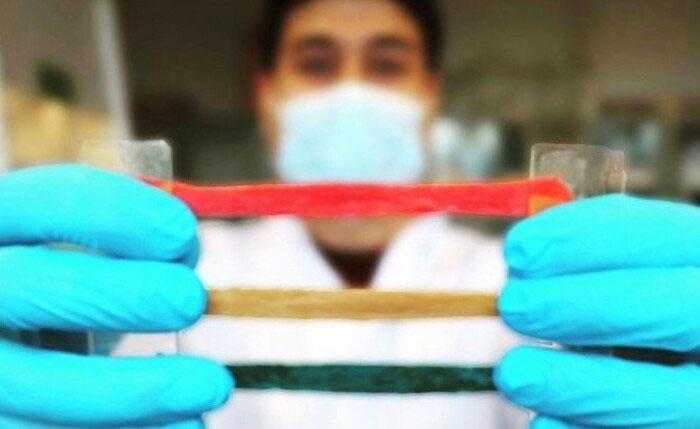

Alireza Dolatshahi-Pirouz, Associate Professor at the Technical University of Denmark, describes the soft material – dubbed CareGum – as a bio-adaptable cyborg sensor that ‘can link or merge synthetic materials and machinery with the human body in a seamless and comfortable manner for both diagnosis and treatment’.

It is fabricated from a polyvinyl alcohol (PVA) polymeric matrix with clay halloysite nanotubes (HNT), and a reactive cross-linker (tannic acid). The HNTs are coated with polydopamine.

Stretchable by up to 30,000%, the material is said to also maintain its electrical properties after 600% strain, self-heal within seconds (both electrically and mechanically), and display strain-sensitivity. It is also printable, mouldable and electrically conductive, add the researchers.

‘We envision that our new material could be used to decipher the complex motion patterns that come into play…[for] real-time monitoring of those who are immobilised because of disease,’ Dolatshahi-Pirouz adds. This could include motor impairment associated with neurological disorders such as Parkinson’s, suggests the team. ‘We have, for example, shown that CareGum can be 3D-printed to a sleeve of stretchable fabric to monitor movements of the hand.’

The team suggests that unlike most of the components employed in today’s cyborg technology, which are based on rigid, non-adaptable and ‘easy-to-break’ electronics, the material exhibits flexibility and self-healing abilities as well as temperature, mechanical strain and perception sensing capacity, describing the material as almost animated. ‘CareGum is not dead material. It is alive. It lives.’

The material, Dolatshahi-Pirouz explains, is also reminiscent of natural tissues. ‘It is ultra-conformable onto curvilinear surfaces like the ones present on native tissues and organs, [and it] displays adhesiveness towards human skin and muscle tissue, while being capable of spontaneously healing itself exactly like natural skin. Despite being one material, the skin tissue displays an incredible portfolio of feats.’

The material is created to mirror the human body both from a mechanical, biological and electromagnetic point-of-view. It operates through ion transportation, like the body.

Dolatshahi-Pirouz states that because CareGum is produced via stirring and mixing of affordable and readily available products, the whole process takes a few minutes making it highly scalable and ripe for commercialisation.

‘In the future, we plan to use CareGum to design devices capable of uniting living tissues with unanimated machinary (cyborganics).’

The team is currently working on the next iteration so it can ‘monitor pH and temperature changes as well as important disease biomarkers’.